Induction Heating Simulation

Optimize Induction Heating Systems

Induction heating uses high-frequency magnetic fields to heat metal directly. EMWorks predicts coil inductance, magnetic flux density, and heating behavior for induction cooktops and power applications.

Explore how cooking evolved from open flames to modern induction cooktops that heat only the pan, not the surface. See how electromagnetic and thermal simulations help optimize power transfer, temperature distribution, and EMF levels for safer, more efficient cooking.

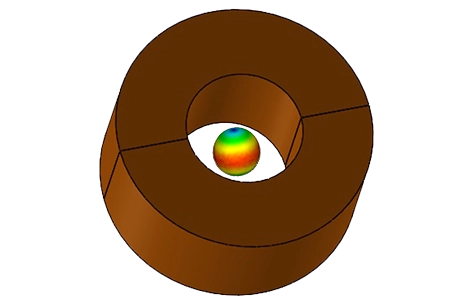

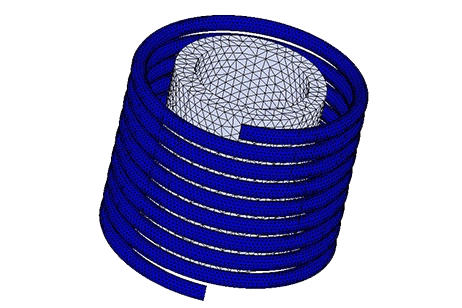

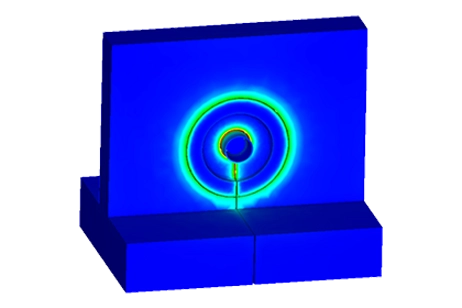

This example uses EMWorks’ Transient Magnetic study coupled with thermal analysis to simulate induction heating of a spherical workpiece inside a multi-turn coil. The solver computes magnetic flux density, eddy current distribution, and temperature evolution so you can study heating rates, penetration depth, and hardening profiles without physical trials.

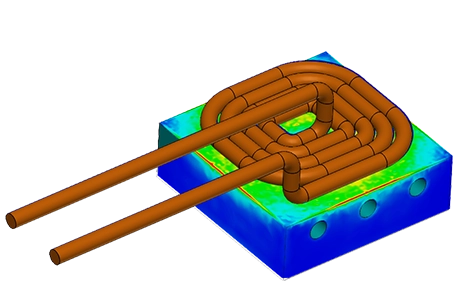

This example uses EMWorks to simulate induction heating of a graphite crucible driven by a multi-turn copper coil. An AC Magnetic study coupled with transient thermal analysis captures frequency-dependent fields, eddy losses, and temperature evolution using temperature-dependent graphite properties.

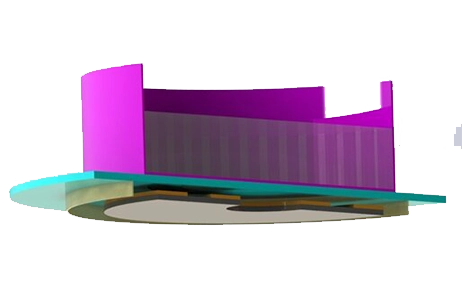

This example uses EMWorks to model magnetic pulse welding of aluminum tubes with a one-turn coil and field shaper, predicting magnetic flux, eddy currents, and temperature rise in the tube during the first current impulse.

EMWorks AC Magnetic and transient thermal analysis compare 3D and 2D induction coils for mold plates, predicting surface temperature distribution and validating results against experiment

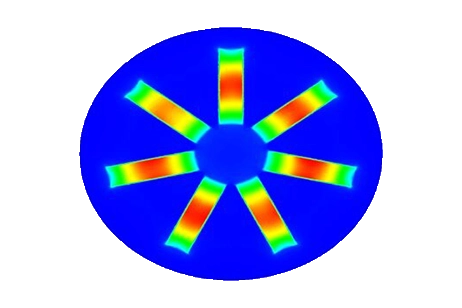

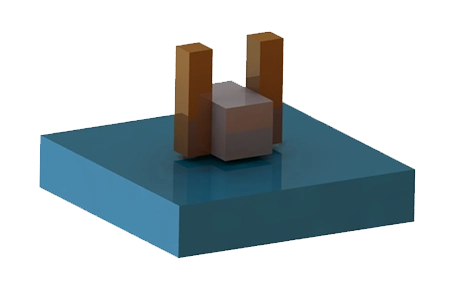

A magnetizer (magnetic flux concentrator) focuses magnetic flux into a target region of a workpiece. Using EMWorks, you can model ferrite magnetizers to boost induction heating efficiency and confine temperature to critical areas.

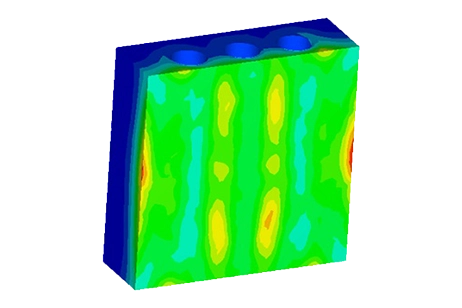

High-frequency proximity heating uses induced currents on facing mold plates to achieve fast, selective surface heating in injection molding. EMWorks couples AC magnetic and transient thermal analysis to predict current density, temperature distribution, and coil settings for precise mold temperature control and shorter cycle times.

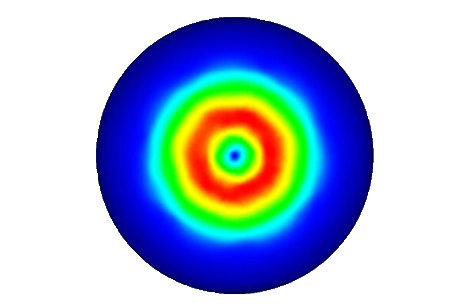

Simulation study of an induction cooktop to find pan material properties and thickness that maximize thermal power under skin effect constraints.