A short description of the device and its operating conditions

Electromagnetic Simulation and Design Services

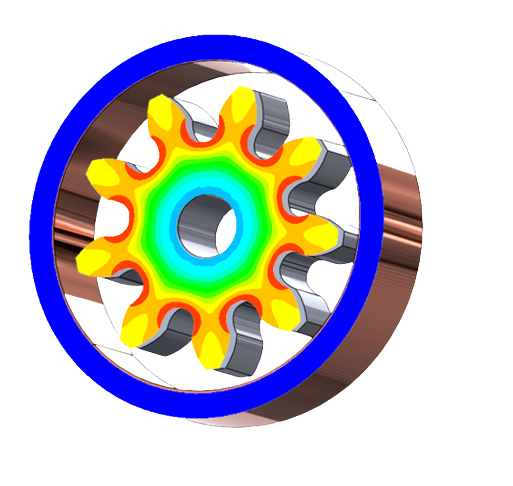

Electromagnetic simulation and design support for motors, transformers, busbars, inductors, sensors, actuators, wireless power systems and RF components.

EMWorks Design and Consulting Services

EMWorks provides electromagnetic design and simulation services for teams that need help with specific projects or additional analysis capacity. Using EMWorks software, we build and run models for devices such as motors, transformers, inductors, busbars, sensors, actuators, wireless power systems and RF components. You keep the models, reports and data so your team can reuse them in future work or continue the studies internally.

Typical Work

Most service projects fall into a few practical categories

Concept and pre-prototype studies

Design comparison

Performance verification

Issue investigation

Design updates

Model setup and handover

Inputs We Typically Need

To scope a project, we usually need a few basic items.

Any existing CAD or simplified geometry

Target performance metrics or a clear statement of the problem

Any available measurements or test data

If some of these are missing, we can still start from an approximate description and refine the details as the work progresses.

Industries and Device Types

We most often support:

- Motor, generator and actuator manufacturers

- Power electronics and power distribution equipment suppliers

- Automotive, aerospace and transportation systems

- Industrial and process equipment

- Medical, sensing and non-destructive testing devices

- RF, antenna and communication hardware

These examples are not limiting; projects outside these areas can be discussed case by case.

Tools and Methods

Projects are carried out using EMWorks software based on finite-element analysis, with 2D and 3D models used as appropriate. Depending on the task, we may:

- Use steady-state, frequency-domain or transient solvers

- Include motion, thermal or structural coupling when needed

- Calibrate models against available measurements before running design variants

Engagement and IP

Project scope, timelines and deliverables are agreed in writing before work starts. Models and results created for your project remain available to your organization for internal use. We work under a non-disclosure agreement so that geometry, materials, operating conditions and results are treated as confidential.

When Our Services Are a Good Fit

Our services are usually a good fit when

- You have a specific device or problem in mind, not just a general interest in simulation

- There is at least one clear question to answer (for example, what torque, loss, temperature, field level or safety margin to expect)

- You have, or can provide, basic geometry and operating conditions

- The results will influence a design decision, test plan or customer discussion

They are usually not a good fit when

- The goal is only a generic benchmark of several tools

- There is no defined device, operating point or deadline

- You are looking to outsource an ongoing engineering role rather than a defined project

Example Projects

The details of each project are confidential, but typical examples include

These examples are representative rather than exhaustive; similar work can be scoped for other devices and applications.

Discuss a Potential Project

Have a project in mind? Share a brief description of your device and operating conditions, and we will suggest whether a project makes sense and what a first step could look like.