Cooking History

Cooking has evolved from open flames to advanced appliances, enhancing taste and safety since prehistoric times. The 20th century saw major advances, with microwaves and induction cooktops speeding up and greening cooking. This piece delves into using EMS technology for creating sustainable, health-focused induction cooktops, showcasing the blend of modern convenience and eco-friendliness in cooking technology.

Figure 1 - Induction cooker

Electro-magneto-thermal coupling in EMS

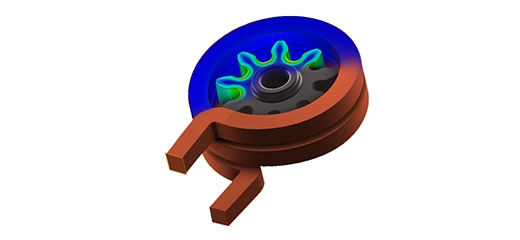

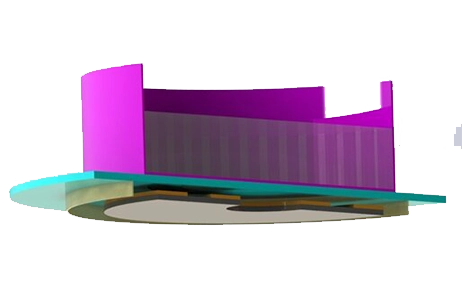

Induction heating intricately combines electromagnetic and thermal processes. In this sophisticated technique, an alternating electric current creates an electromagnetic field, which then generates eddy currents in the material being heated. These eddy currents transform into heat, ensuring even distribution throughout the material. Tackling this complex interaction is challenging for engineers. However, EMS technology facilitates this by allowing for the integration of electromagnetic and thermal analyses. Conducting AC magnetic studies along with thermal analysis provides essential information, including magnetic flux density, applied and eddy current densities, inductance values critical in power electronics, and details on temperature and heat flux. This demonstrates the application of these principles in designing efficient induction heating systems, exemplified by a CAD model of a commercial induction cooktop.

.

Figure 2 - The work coil situated at the bottom of the table

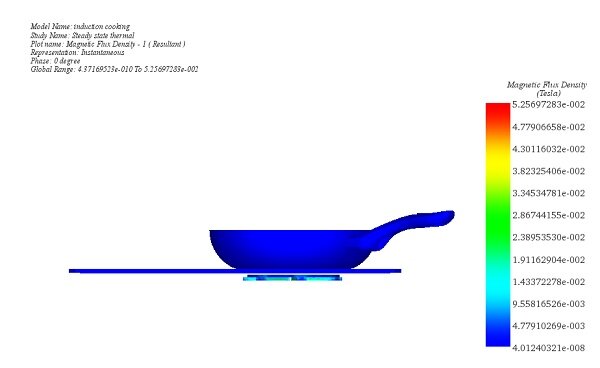

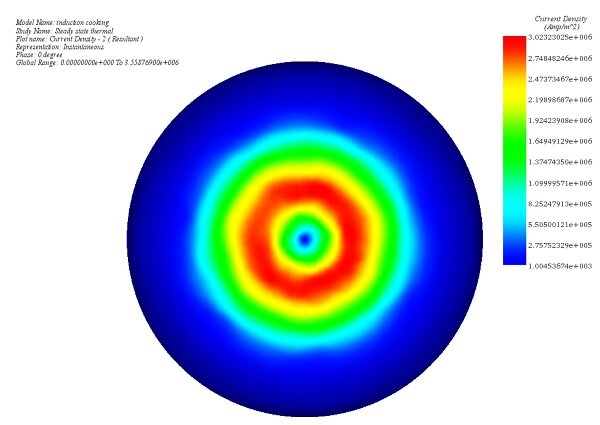

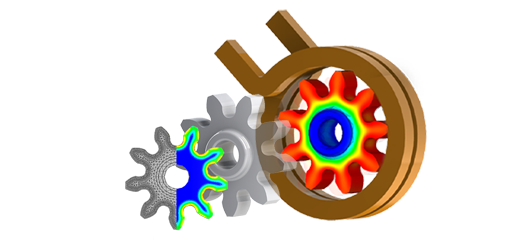

Figure 3 illustrates how the magnetic flux in induction cookware is focused primarily on the iron cores. Meanwhile, Figure 4 highlights the presence of eddy currents at the bottom of the pan, showcasing the underlying principles of induction cooking technology. This visualization helps in understanding the efficiency of induction cooktops in concentrating heat where it's most needed, offering insights into the advanced mechanics of modern cooking appliances.

Figure 3 - Magnetic flux density around the cooktop

Figure 4 - Eddy current density generated in the pan, fringe, and vector plot

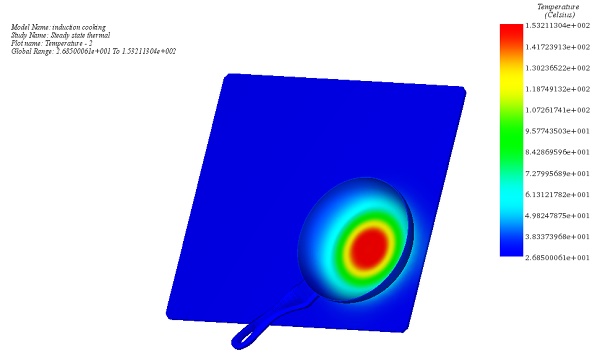

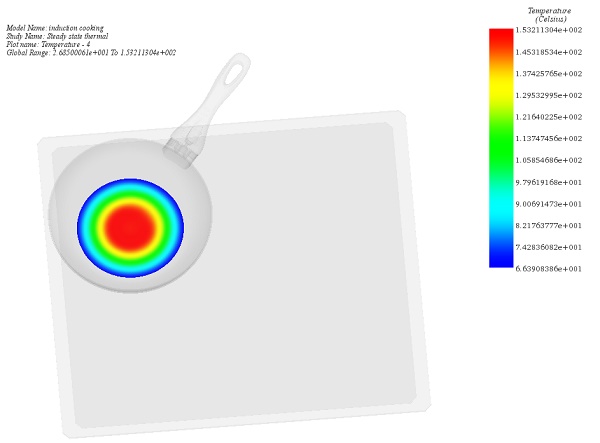

Figures 5a and 5b provide a clear visualization of the temperature distribution across the entire cooktop and within the pan, respectively. These images offer valuable insights into how heat is uniformly dispersed in induction cooking, demonstrating the precision and efficiency of this modern cooking technology.

Figure 5 - Temperature distribution, a) in the whole model b) in the surface of pan

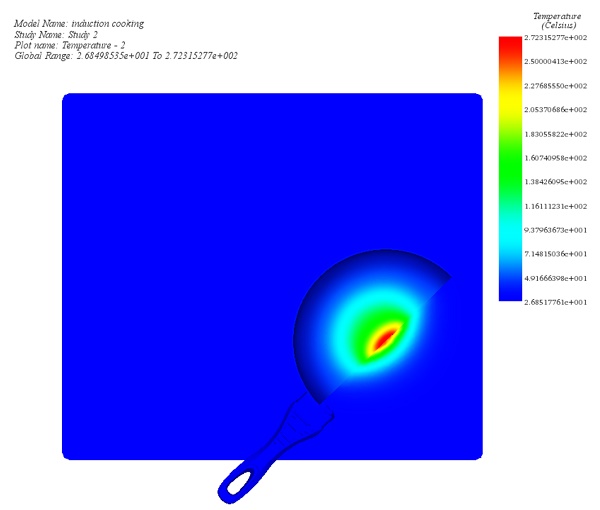

Figure 6 - Temperature in half a pan (it shows that the heat is located on the pan)

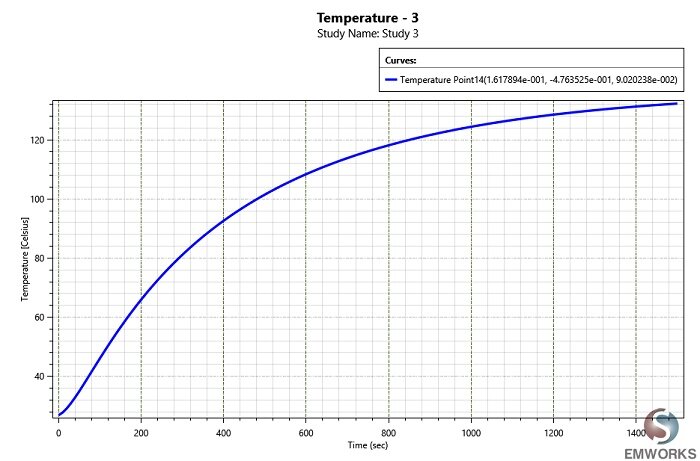

The figure presented below captures the changes in temperature over time at a specific point on the bottom of the pan. This visualization offers a detailed look at how heat evolves during the cooking process in induction cookware, highlighting the precise control induction cooking technology provides over temperature.

Figure 7 - Temperature variation in the bottom of the pan

What is the Induction cooking risk?

Every cooktop has its risks, from electric burn hazards to gas leaks. Induction cooktops raise safety concerns over electromagnetic fields (EMFs) affecting health. Yet, precautions like using suitable cookware and maintaining distance can minimize exposure. EMS technology helps engineer safer induction cooktops by limiting EMF exposure, ensuring they meet safety standards for minimal risk to users with specific health conditions.

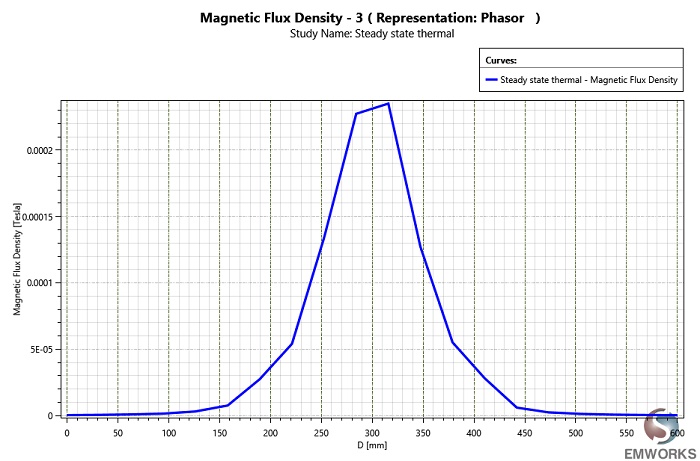

Figure 8 - Variation of magnetic flux density in a circle of 30 cm radius

Conclusion

This application note explores the evolution of cooking technologies, focusing on the transition from open flames to advanced induction cooktops, which represent a significant leap in culinary efficiency, safety, and environmental sustainability. It highlights the role of EMS technology in the development of modern, eco-friendly cooking appliances that prioritize health and convenience. By leveraging electro-magneto-thermal coupling, EMS enables the intricate integration of electromagnetic and thermal analyses essential for the efficient design of induction heating systems. This approach allows for detailed simulations of magnetic flux density, eddy currents, and temperature distribution, providing valuable insights into the functionality and efficiency of induction cooktops.

The visualizations presented, including the focused magnetic flux in cookware and the generation of eddy currents at the bottom of the pan, underscore the precision of induction technology in targeting heat delivery. Moreover, temperature distribution models demonstrate the uniform heating capabilities of induction cooktops, showcasing their advantage in cooking precision and energy efficiency.

However, the note also addresses safety concerns associated with induction cooking, particularly the potential health risks posed by electromagnetic fields (EMFs). It outlines how EMS technology can aid in designing safer induction cooktops by minimizing EMF exposure, ensuring they conform to safety standards, and pose minimal risk to users.

-(1).webp)