Electro-Thermal Multiphysics Simulation

Couple electrical losses and heat flow to predict temperature and reliability.

This application note demonstrates how EMWorks electro-thermal FEA is used to design and optimize magnetic pulse welding of aluminum–steel sheets with a one-turn E-shaped coil. By analyzing current density and temperature distribution, engineers can fine-tune process parameters to achieve reliable, high-quality solid-state joints for automotive, aerospace, and industrial applications.

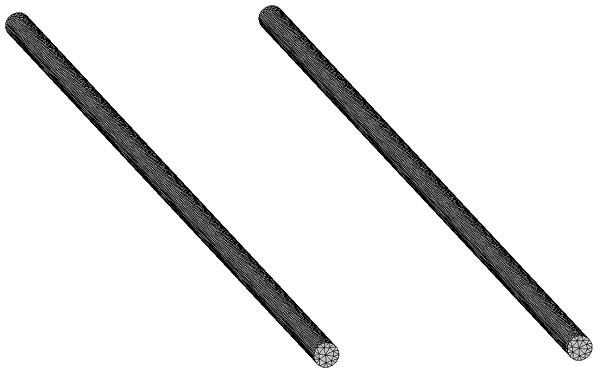

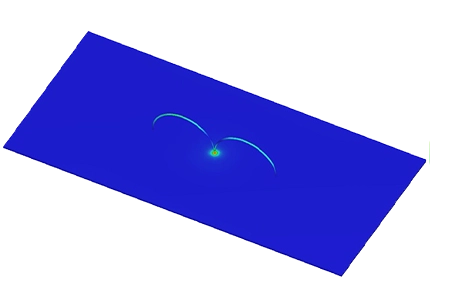

This example uses two parallel current-carrying wires to demonstrate EMWorks’ coupled transient magnetic and thermal analysis. A pulsed current excites the conductors, and the solver computes time-varying magnetic fields, induced currents, solid (ohmic) losses, and the resulting temperature rise, allowing you to verify accurate energy transfer between electromagnetic and thermal domains.

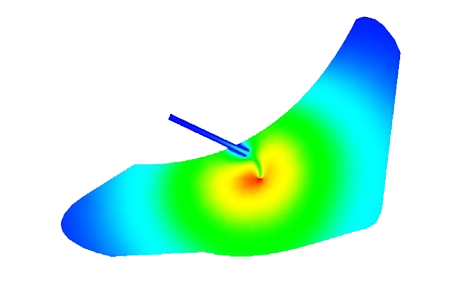

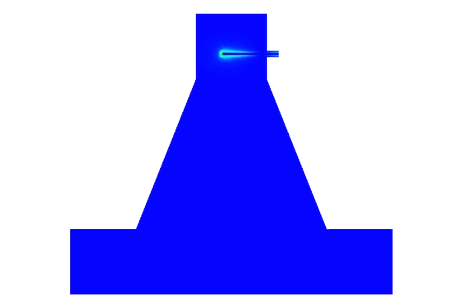

This application note presents a 2.45 GHz open-tip coaxial antenna for RF microwave ablation of the soft palate to treat snoring and OSA. Using EMWorks RF & Microwave, you can predict electric and magnetic fields, tissue temperature rise and heat flux to size the applicator, set input power and exposure time, and improve treatment safety and effectiveness.

This note analyzes two 2.4 GHz Wi-Fi antennas—a Biquad radiator with a metallic reflector and a B-shaped dual loop over FR-4—using EMWorks electromagnetic simulation. It reports return loss, gain, radiation patterns, and basic thermal behavior to support practical wireless antenna design.

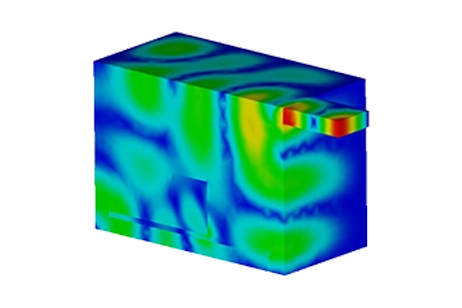

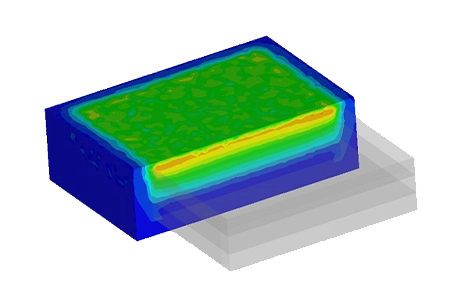

This note models microwave heating of a coal sample in a 2.45 GHz rectangular cavity, solving coupled electromagnetic and thermal fields to quantify power absorption, loss distribution and steady-state temperature. The study reports coal volume losses, wall surface losses and temperature profiles for a 500 W excitation.

This note models RF heating of soybean flour placed between parallel plate electrodes in a 6 kW, 27.12 MHz system. The study uses finite element analysis to compute electric and magnetic fields, dielectric and conductor losses, and the resulting temperature distribution across three flour layers and supporting polystyrene components.

This application note studies microwave heating of asphalt mixtures using a coaxial-fed pyramidal horn antenna in the 700–1300 MHz band. A first study characterizes the antenna in air through return loss and gain patterns; a second study includes an asphalt sample and couples electromagnetic and thermal analyses to compute electric field distribution, volume loss density and temperature rise under 800 W excitation.

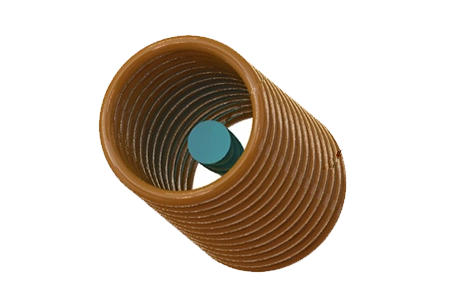

This application note studies induction brazing of a cylindrical copper workpiece using 3D coupled electromagnetic–thermal finite element analysis. A 13-turn copper coil operating at 75 kHz with a peak current of 300 A is modeled to quantify magnetic field distribution, eddy current density, ohmic losses and resulting temperature rise in the workpiece. The results show surface-concentrated currents due to the skin effect, non-uniform temperature between 26°C and 28.24°C after 1 s, and clear links between field distribution, power loss and thermal response, providing a basis for refining induction coil and process parameters.

-Techniques.webp)