MEMS Simulation with EMWorks

Design, analyze, and optimize MEMS sensors and actuators.

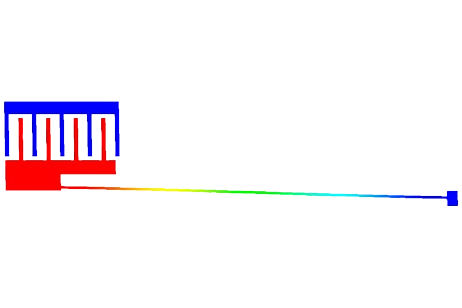

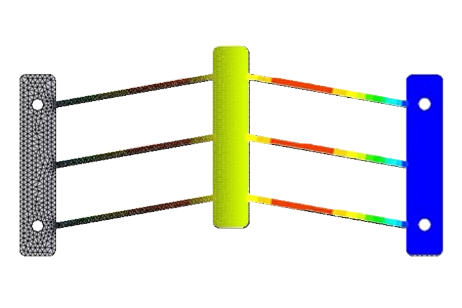

This example models a PolySilicon comb-drive actuator in EMAG, applying fixed voltages and structural constraints to compute electrostatic force, displacement and spring restoring force for validating MEMS actuator performance.

This case study models an electro-thermal MEMS micro-gripper in EMWorks, using coupled electrical, thermal, and structural simulation to predict temperature rise in the hot arm and tip displacement under low DC voltage.

This case study uses EMWorks to simulate a low-voltage polysilicon MEMS thermal actuator. A coupled electrical–thermal–structural model predicts temperature rise in the hot arm and resulting tip deflection, matching published reference results.

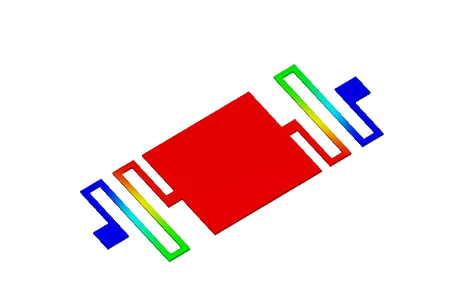

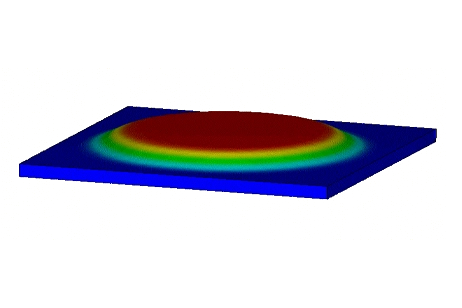

This example uses EMWorks to model a MEMS microsensing membrane formed by two square electrodes and serpentine springs. The electrostatic–structural simulation predicts membrane deflection versus applied DC voltage and validates the results against reference data.

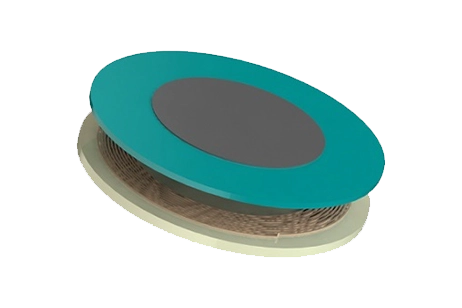

This note shows how EMWorks simulates a 4×4 magnetic micro-actuator array with PDMS membranes, micromagnets, and coils to predict actuation force and tip deflection for tactile haptic feedback.

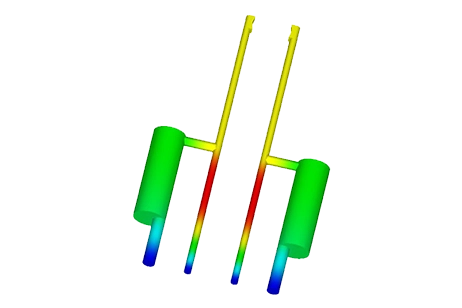

EMWorks simulates a MEMS V-beam thermal actuator using coupled electrical, thermal, and structural analysis to predict resistance, temperature distribution, and shuttle deflection under DC excitation.

This note shows how EMWorks models a MEMS valveless micropump driven by electromagnetic actuation, computing magnetic force and PDMS membrane deflection for microfluidic applications.