Micro-Electro-Mechanical Systems

MEMS drives micro-scale device exploration, notably in biomedical sectors with embedded microfluidic devices. Micropumps, crucial for drug delivery and chemical analysis, rely on electromagnetic actuation. Valveless-actuated micropumps are common in this field, reflecting the evolving microfluidic landscape.

Micro-valveless-actuated pump

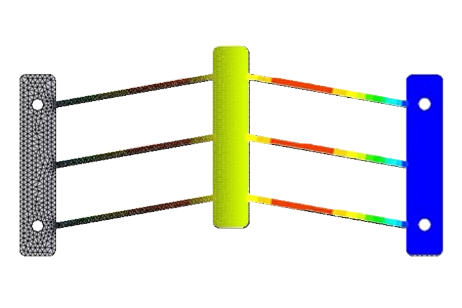

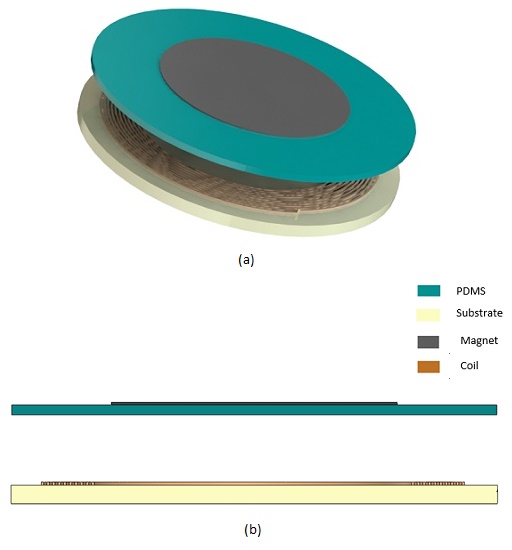

This application note investigates a micro-valveless pumping mechanism comprising an electroplated permanent magnet and a fixed micro coil. By applying current to the coil, fluid is propelled through the pump via electromagnetic force. PDMS is selected for its flexibility, allowing for precise flow rate control with minimal electrical input. Figure 1 showcases the prototype and actuation mechanism.

![A picture of the fabricated micro-pump [1] a). and its schematic illustration b).](/ckfinder/userfiles/images/A-picture-of-the-fabricated-micro-pump-%5B1%5D-a%29-and-its-schematic-illustration-b%29.jpg)

CAD Model

In this analysis, the magnetostatic module of EMS, coupled with structural study, computes and visualizes the mechanical deflection of the flexible membrane subjected to magnetic loads from the coil-magnet interaction. Figure 2 illustrates the design of the micro-pump.

The following tables define the dimensions of the main model components:

| Material | Radius (µm) | Thickness (µm) | Elastic limit force (µN) |

| PDMS | 1950 | 80 | 315 |

| Material | Inner Radius (µm) | Outer Radius (µm) | Width (µm) | Turns | Resistance (?) |

| Copper (Cu) | 1250 | 1725 | 25 | 10 | 3.23 |

| Material | Radius (µm) | Thickness (µm) | Distance from coil base (µm) |

| CoNiMnP | 1150 | 20 | 620 |

Material Properties

| Material | Density (Kg/$$ \text{m}^3 $$) | Magnetic permeability | Electrical conductivity (S/m) | Elastic Modulus (Pa) | Poisson’s ratio | Magnetization Coercivity (A/m) Remanence (T) |

| Copper (Cu) | 8900 | 0.99 | 5.7 E+07 | Not required | Not required | |

| PDMS | 1030 | 1 | 0 | 0.75 E+6 | 0.49 | |

| Glass | Not required | 1 | 0 | Not required | ||

| CoNiMnP | 1.88 | 0 | 47700 0.3 | |||

Electromagnetic Inputs

The inductor coil is modeled as a solid coil supporting a current input range of 0.4 to 1 A RMS.

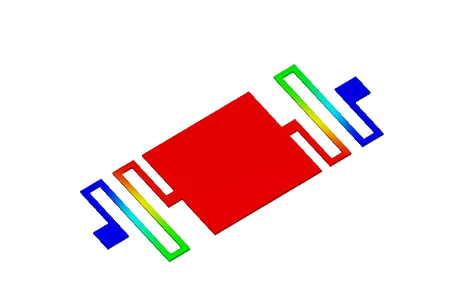

Mechanical boundary conditions

Fixed boundary conditions are applied to the lateral cylindrical surface of the PDMS membrane, as depicted in Figure 3.

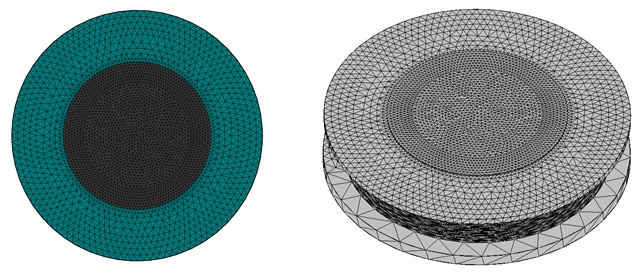

Meshing

Figure 4 - Top and isometric view of the meshed model

Results

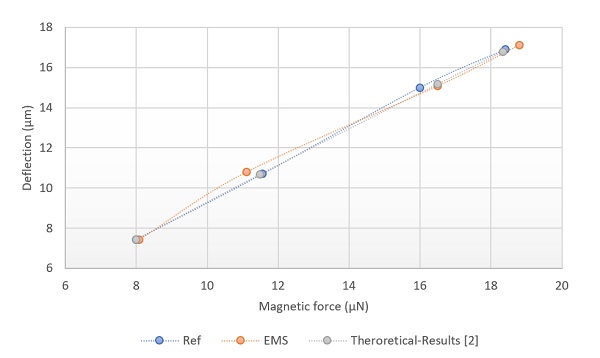

To achieve the required actuation force and diaphragm deflection as specified in reference [2], numerical simulations were conducted using the EMS tool. Various current inputs ranging from 0.4A to 1A were applied, and the corresponding results are depicted in the figures below. Figure 5 illustrates the variation of the resultant magnetic force concerning the applied current inputs. Remarkably, there is a high coherence between the results obtained from the EMS tool and those referenced in [2].

![Magnetic force variation versus current inputs for both Reference [2] and EMS results.](/ckfinder/userfiles/images/Magnetic-force-variation-versus-current-inputs-for-both-Reference-%5B2%5D-and-EMS-results..jpg)

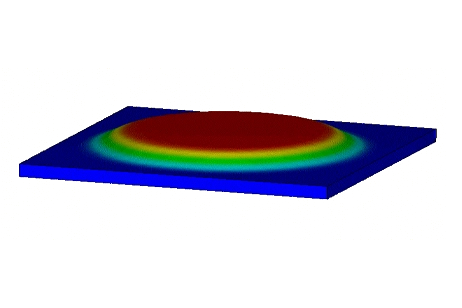

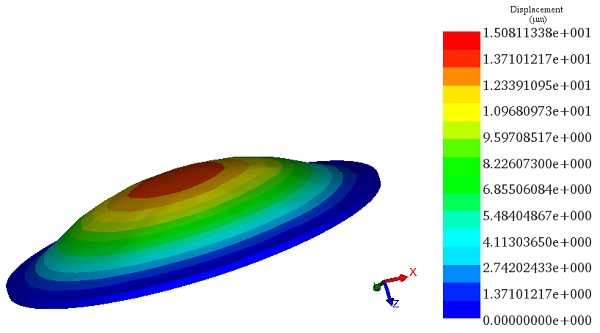

Under the influence of the magnetic force, the PDMS diaphragm bends upwards, reaching a maximum deflection of 15.08 µm under 16.5µN, corresponding to a current input of 0.9A (Figure 6). These findings closely align with the desired membrane displacement specified in Reference [2], enhancing the micro-scale pump's capability to achieve substantial membrane deflection while minimizing energy consumption.

Figure 7 provides a secondary comparison between the simulation results from Reference [2], analytical [2], and EMS. It illustrates the 2D plot variation of membrane deflection against the magnetic force obtained for the current range [0.4A..1A]. This comparison reaffirms the excellent agreement among the various results and underscores EMS's capability to accurately estimate the magneto-mechanical behavior of micro-pump actuation, particularly under low currents.

Conclusion

This application note delves into the advancement of Micro-Electro-Mechanical Systems (MEMS), particularly focusing on a micro-valveless pumping mechanism for applications in drug delivery and chemical analysis. The mechanism, leveraging electromagnetic actuation, features a unique design incorporating an electroplated permanent magnet and a fixed micro coil. The use of Polydimethylsiloxane (PDMS) for the flexible membrane allows for controlled fluid propulsion through electromagnetic forces with minimal electrical input, highlighting the pump's efficiency and precision.

The study employs the magnetostatic module of EMS, coupled with structural analysis, to compute the mechanical deflection of the flexible membrane under magnetic loads, showcasing the interaction between the coil and the magnet. This analysis provides insights into the operational dynamics of the micropump, demonstrating its potential for precise flow rate control in microfluidic applications.

Results from various current inputs ranging from 0.4A to 1A reveal a direct correlation between the applied current and the resultant magnetic force, as well as the membrane's deflection. These findings not only validate the EMS tool's accuracy compared to the referenced data but also emphasize the micropump's capability to achieve significant membrane deflection with optimized energy use.

In conclusion, this application note illustrates the effectiveness of electromagnetic-thermal NDT in advancing MEMS technology for biomedical applications. By accurately simulating the magneto-mechanical behavior of micro-pump actuation, it underscores the potential of MEMS devices in enhancing drug delivery systems and chemical analysis through innovative microfluidic solutions.

References

[1]- Lee, Chia-Yen, Hsien-Tsung Chang, and Chih-Yung Wen. "A MEMS-based valveless impedance pump utilizing electromagnetic actuation." Journal of Micromechanics and Microengineering 18.3 (2008): 035044.

[2]- Chang, Hsien-Tsung, et al. "Theoretical analysis and optimization of electromagnetic actuation in a valveless microimpedance pump." Microelectronics journal 38.6-7 (2007): 791-799.