PMSMs

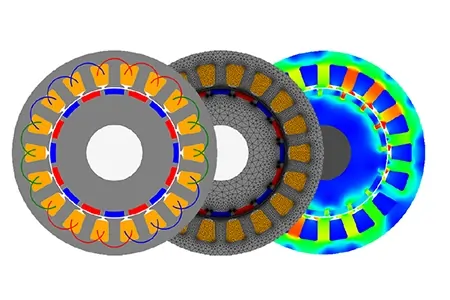

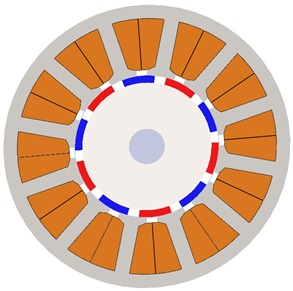

Permanent Magnet Synchronous Machines (PMSMs) are essential in electric vehicles and traction applications for their steady-state operation, high efficiency, and torque density, exemplified by models like the Toyota Prius. This application note presents the computation and validation of cogging torque in a Surface-Mounted PMSM using EMWorks2D, as shown in Figure 1. It further explores the effect of permanent magnet segmentation on cogging torque utilizing the "multi-configuration" feature.

Simulation and results

1- No-Load analysis of the original model

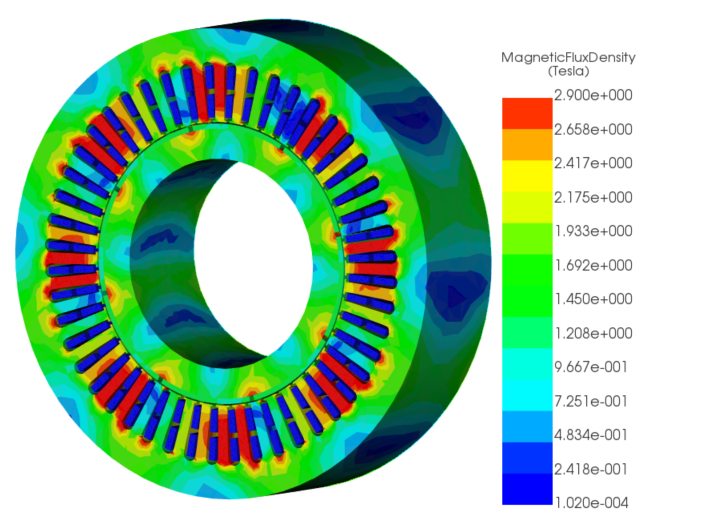

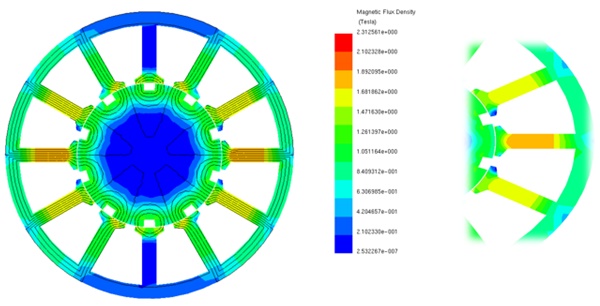

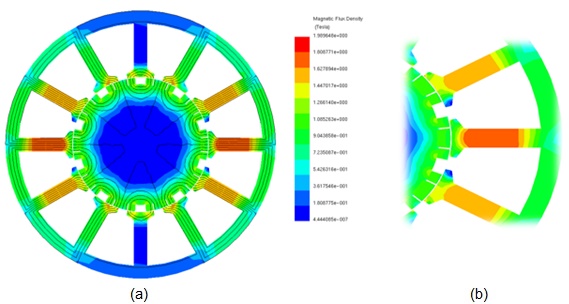

The magnetic field mapping for the original surface-mounted PMSM motor at an initial 0-degree angular position is simulated using EMWorks2D, as depicted in Figure 2.

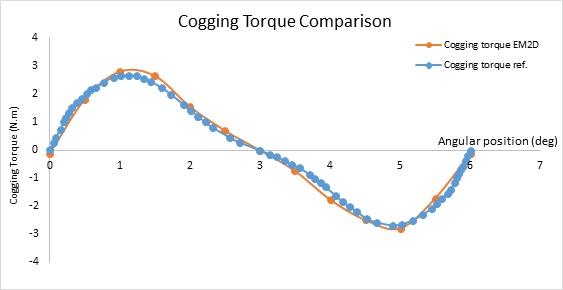

The magnetic field reaches its maximum when the stator tooth aligns fully with the pole. The cogging torque of the original PMSM, plotted against angular position over one period, is computed and validated using EMWorks2D, as demonstrated in Figure 4.

The original PMSM's cogging torque exhibits a peak-to-peak value of 5.58N.m and an average value of -0.0185N.m.

2- Effect of magnet segmentation on the cogging torque of the PMSM

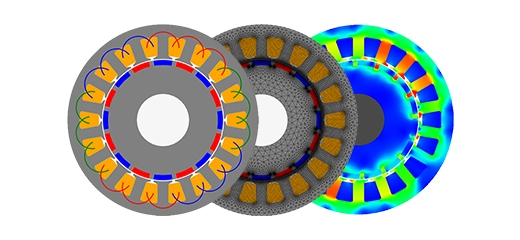

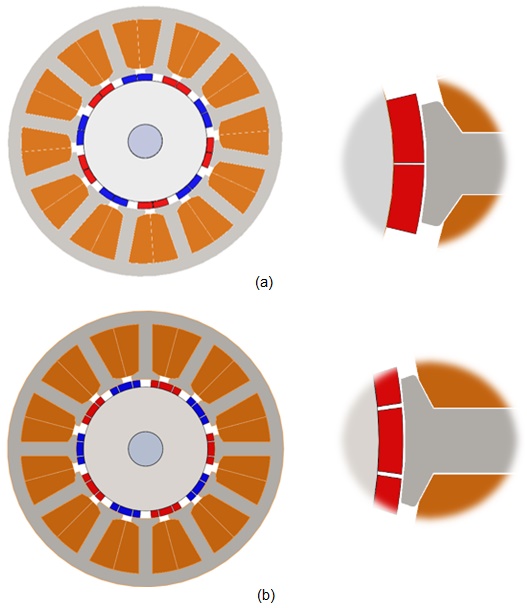

Two case studies using EMWorks2D investigated the effect of magnet segmentation on no-load torque, with permanent magnets segmented into two and then three blocks each, as shown in Figure 5.

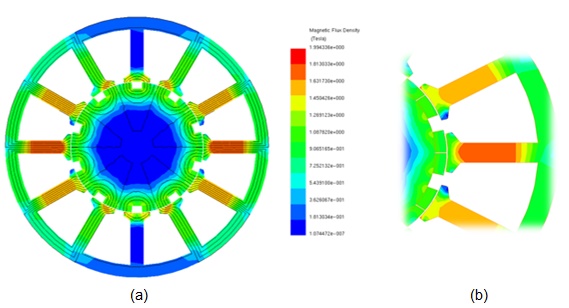

The magnetic field mappings for the PMSMs with one and two segmentations of the permanent magnets are depicted in Figures 6 and 7, respectively.

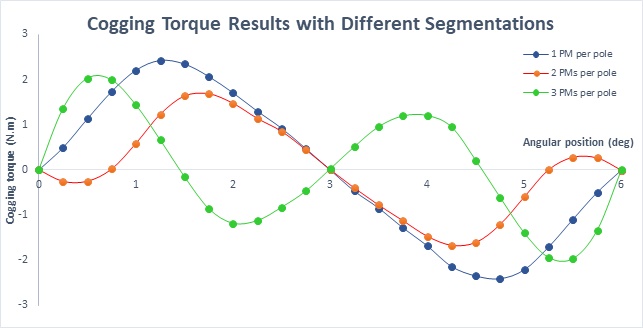

The cogging torque for different segmentation cases of the PMSMs was computed using EMWorks2D, with results presented in Figure 8. To emphasize the impact of permanent magnet segmentation on cogging torque, both peak-to-peak and average values are detailed in Table 1.

| Cogging torque | 1 PM per pole | 2 PMs per pole | 3 PMs per pole |

| Peak-to-peak value (N.m) | 5.4629 | 3.355 | 3.99478 |

| Average value (N.m) | 0.01486 | 0.011802 | 0.029759 |

From Table 1, it's apparent that the average cogging torque across the configurations is nearly zero, suggesting any differences might be attributed to computational errors. Notably, in the second configuration with two PMs per pole, the peak-to-peak cogging torque significantly decreases, while it slightly increases in the third configuration.

Conclusion

The application note delves into Permanent Magnet Synchronous Machines (PMSMs), vital components in electric vehicles and traction systems due to their efficiency and torque density. Focused on a Surface-Mounted PMSM, it investigates cogging torque using EMWorks2D simulations and examines the impact of magnet segmentation. Initial analysis of the original model reveals cogging torque patterns, with subsequent studies exploring the effect of permanent magnet segmentation. Results showcase variations in cogging torque values across different magnet segmentation configurations. Notably, while average cogging torque remains minimal across configurations, significant changes are observed in peak-to-peak values. The note concludes by noting the potential computational errors affecting results and highlighting the significance of magnet segmentation in mitigating cogging torque.

References

[1] A. Frikha, “Contribution to the Multiphysics Modelling of Permanent Magnet Synchronous Machines”, Master Thesis, National Engineering School of Sfax, Tunisia, 2019.