Optimize Magnetic Gears with EMWorks Software

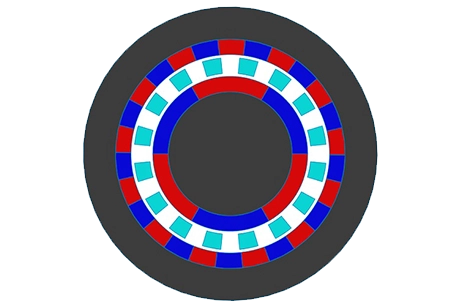

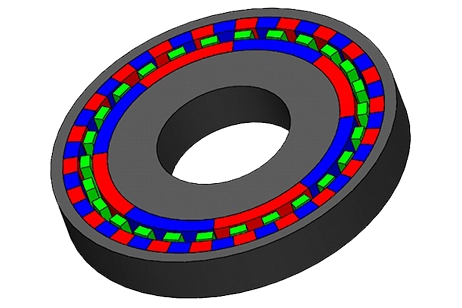

Empowering Magnetic Gear Innovations through Electromagnetic Design

Learn how magnetic gears outperform traditional gears with zero friction, lower maintenance, and unmatched efficiency in our comprehensive analysis.

Learn how magnetic gears offer a frictionless, maintenance-free alternative to traditional gears, enhancing efficiency and reliability in the automotive and marine sectors.

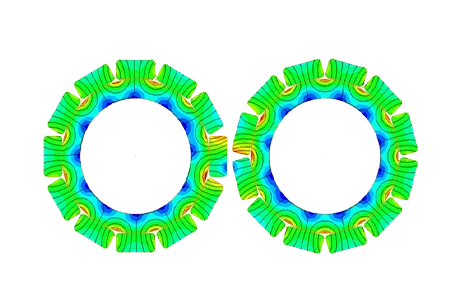

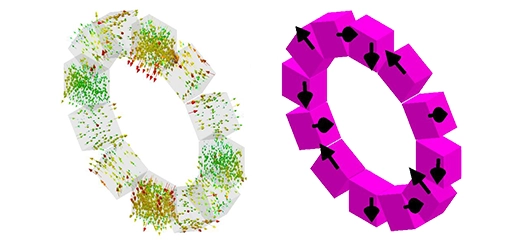

Learn how air gap lengths and magnet shapes influence torque transmission and efficiency in magnetic gears, as revealed in our latest EMWorks2D simulation study.