Magnetic Levitation Vehicle Simulation

Design and optimize maglev bearings, guides, and propulsion systems in 3D.

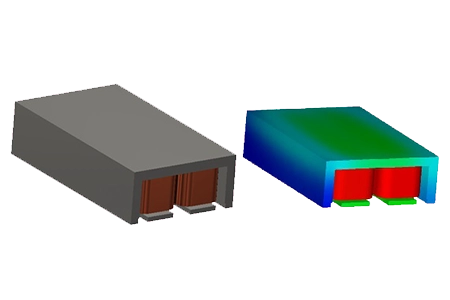

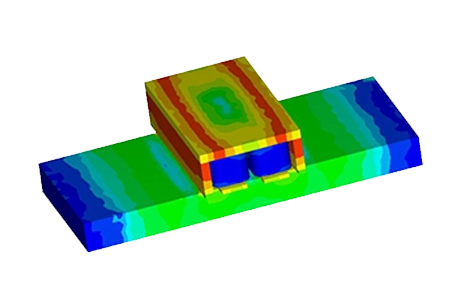

This note uses Autodesk Inventor and EMWorks to study an electromagnet lifting machine, evaluating force vs current, core saturation for different steels, and coil temperature rise.

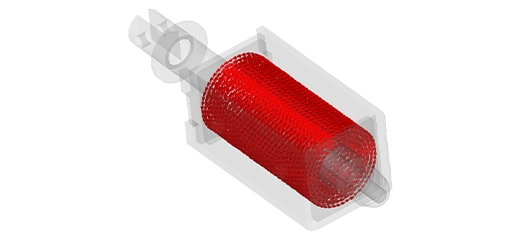

This example models a magnetic lifting machine using EMWorks’ Magnetostatic module. Stranded coils energize magnetized steel cores, and the solver computes flux density in the cores, air gap, and steel load plus the resulting lifting force. The study helps you size coils, cores, and air gaps to safely handle heavy plates and scrap in industrial environments.

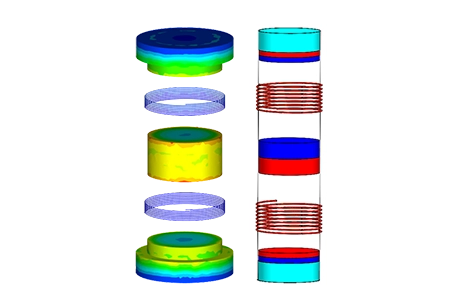

This application note explores magnetic levitation–based energy harvesters that convert ambient vibrations into electricity using floating magnets and coaxial coils. Several topologies—single-coil, bistable, and multi-coil/multi-magnet including Halbach configurations—are modeled in EMWorks to study restoring force, induced voltage, and magnetic flux density. The results show how simulation can optimize magnet layouts and coil arrangements to maximize energy capture, stability, and efficiency in compact renewable energy devices.

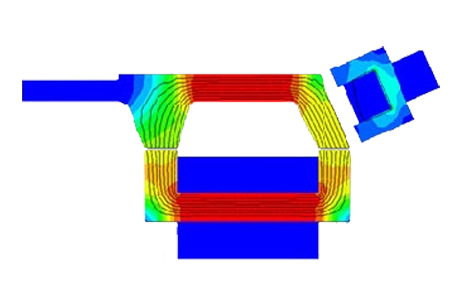

This article analyzes an electromagnetic levitation system for a semi-high-speed maglev train using EMWorks. It examines levitation and guidance forces versus airgap, current, and lateral deviation, then compares three design configurations to identify an optimized levitation layout.