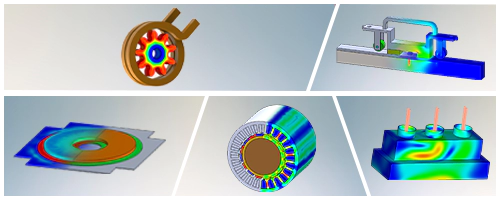

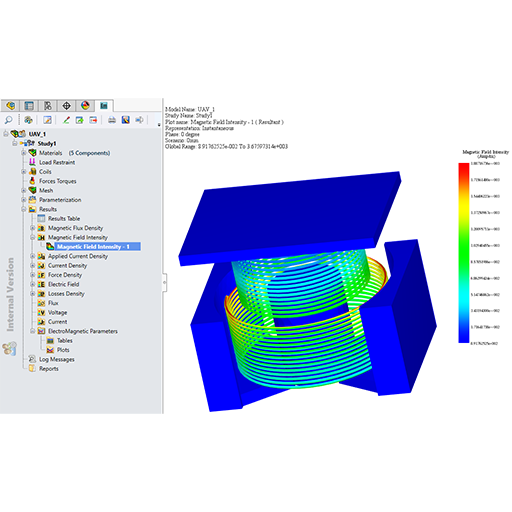

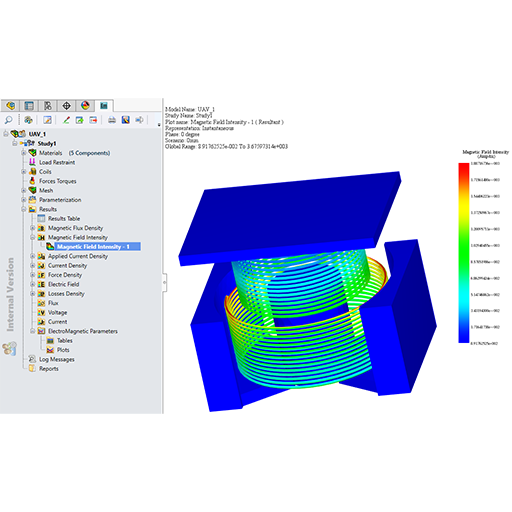

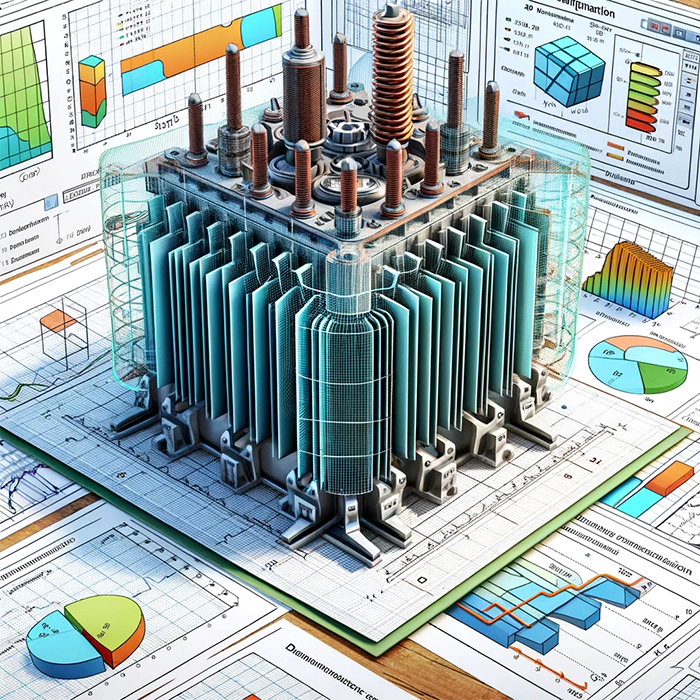

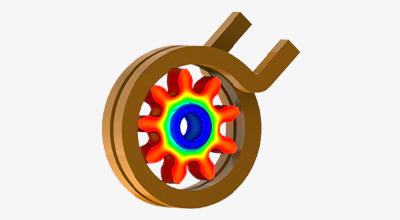

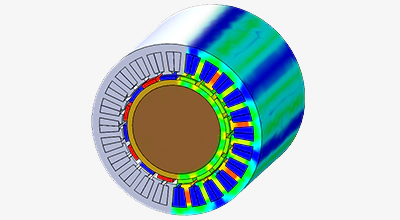

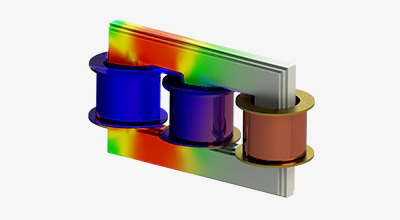

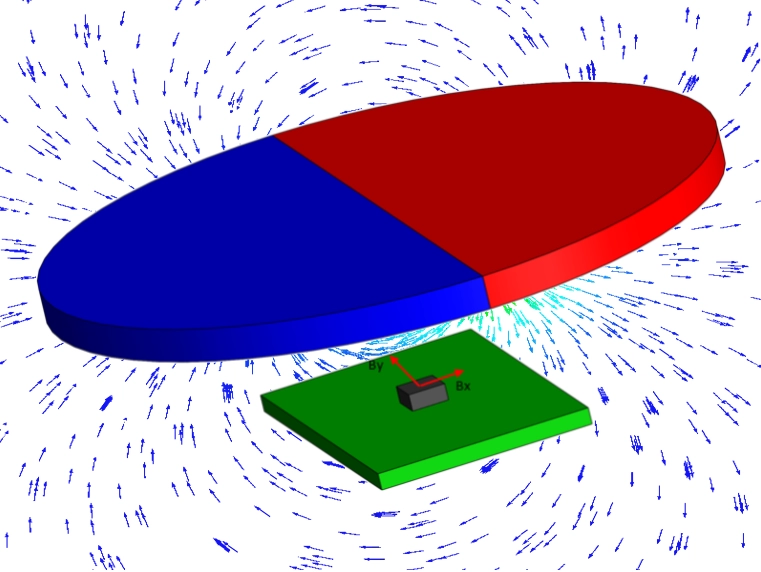

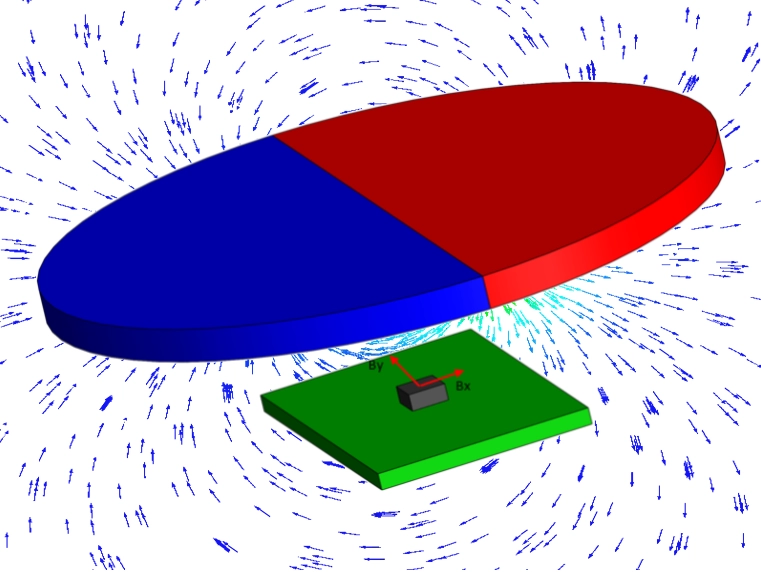

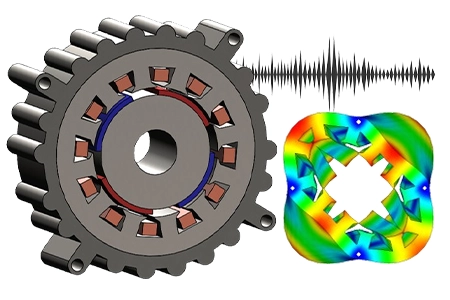

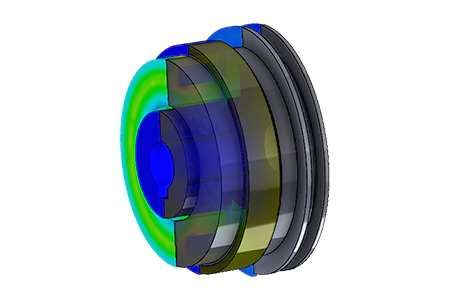

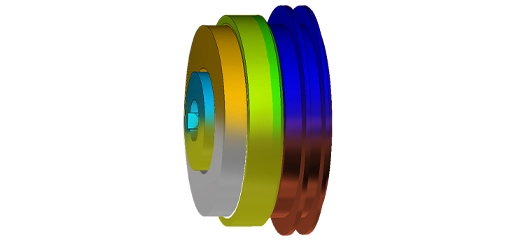

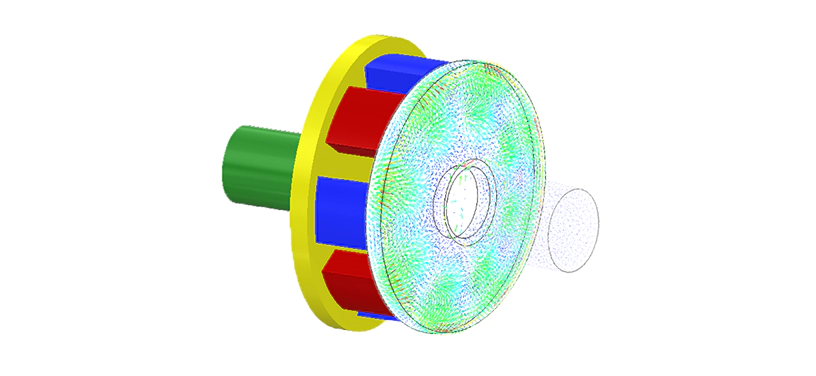

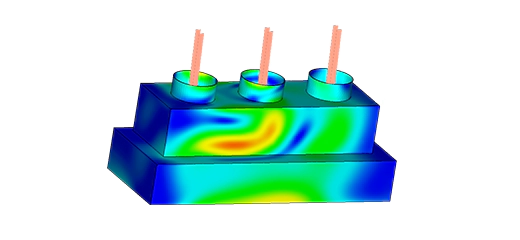

EMS, Unsere vielseitige elektromagnetische Simulationssoftware steht als leistungsstarkes Finite-Elemente-Paket mit breit gefächerten Anwendungen in Schlüsselindustrien wie Automobil, Energie, Energie, Luft- und Raumfahrt und Verteidigung. Ihre Fähigkeiten erstrecken sich über verschiedene Anwendungsfälle, darunter Leistungselektronik, Motoren, Transformatoren, magnetische Feldanalyse, elektrische Feldanalyse sowie Hochspannungs- und Hochleistungssysteme. Ingenieure und Forscher vertrauen auf EMS, um ihre Designs zu optimieren, die Effizienz zu steigern und das elektromagnetische Verhalten in diesen anspruchsvollen Umgebungen zu analysieren. Ob Ihr Ziel darin besteht, die Leistung eines Elektromotors zu feinabstimmen, Transformatoren für Hochleistungsanwendungen zu bewerten oder Herausforderungen durch elektromagnetische Interferenzen zu bewältigen, EMS stellt Ihnen robuste Werkzeuge und unerschütterliche Präzision zur Verfügung, um Ihre Ziele effektiv zu erreichen.

EMS trägt die renommierte Goldzertifizierung als SOLIDWORKS®-Add-In und integriert sich nahtlos mit Autodesk® Inventor®, um Ihre CAD-Design-Workflows zu verbessern. Importieren Sie Millionen kostenloser 3D-CAD-Modelle aus Online-Repositories und führen Sie sofortige elektromagnetische Feldsimulationen durch. Passen Sie Parameter an, um mehrere Designszenarien zu erkunden und Ihre Leistung mühelos zu optimieren.

EMS präsentiert eine intuitive, benutzerfreundliche grafische Benutzeroberfläche für mühelose Navigation und Zugänglichkeit. Erkunden Sie umfangreiche Schulungsmaterialien durch den integrierten Demo-Viewer. Durch den Einsatz modernster Finite-Elemente-Löser und fortschrittlicher Netzgenerierungstechnologien garantiert EMS präzise und zuverlässige Ergebnisse.

The EMWorks engineers were not only very collaborative and available, but have offered great consulting support, building the models and running all required simulation scenarios, as well as preparing final reports, delivering a summary of the work results and the fine-tuned 3D models. I appreciate all the help and support from EMWorks, and I will recommend EMS to colleagues of my team specialized in FEA, as this would be a precious tool to have in-house.

The EMWorks engineers were not only very collaborative and available, but have offered great consulting support, building the models and running all required simulation scenarios, as well as preparing final reports, delivering a summary of the work results and the fine-tuned 3D models. I appreciate all the help and support from EMWorks, and I will recommend EMS to colleagues of my team specialized in FEA, as this would be a precious tool to have in-house.

Giorgio Giovanni Battista Zaffaroni

EMWorks played a pivotal role in facilitating our research and development efforts, and we extend our gratitude to the team for providing us with a tool that greatly contributed to our project's accomplishments. We look forward to the opportunity to explore its capabilities further in future endeavors.

EMWorks played a pivotal role in facilitating our research and development efforts, and we extend our gratitude to the team for providing us with a tool that greatly contributed to our project's accomplishments. We look forward to the opportunity to explore its capabilities further in future endeavors.

Truls Nilsson

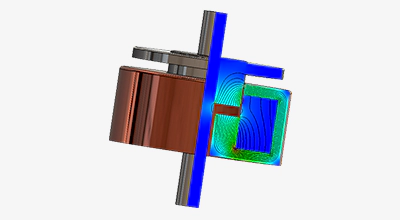

EMS helped us design our Lorentz force electromagnet to determine the strength of the system. We augmented our power input and placed our permanent magnets to optimize force output. EMS was easy to update through our many iterations of SOLIDWORKS models. We produced nearly a dozen different CAD configurations and tested several of them, leveraging theoretical EMS models and practical setups with 3D printed parts.

EMS helped us design our Lorentz force electromagnet to determine the strength of the system. We augmented our power input and placed our permanent magnets to optimize force output. EMS was easy to update through our many iterations of SOLIDWORKS models. We produced nearly a dozen different CAD configurations and tested several of them, leveraging theoretical EMS models and practical setups with 3D printed parts.

Team 3 - Virginia Tech