Microwave Heating

Conventional heating relies on thermal conduction and convection, leading to slow, inefficient heat transfer due to material properties and energy loss. In contrast, microwave heating uses electromagnetic radiation to directly convert energy into heat within the sample, based on its dielectric properties, ensuring rapid, volumetric heating and minimizing energy waste. This method, advantageous for its efficiency and suitability for hazardous environments, has been widely adopted in industry. This study employs HFWorks to model the microwave heating process of coal, demonstrating the technique's effectiveness through numerical analysis of coupled electromagnetic and heat transfer equations.

Problem description

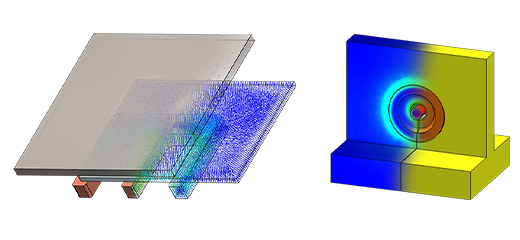

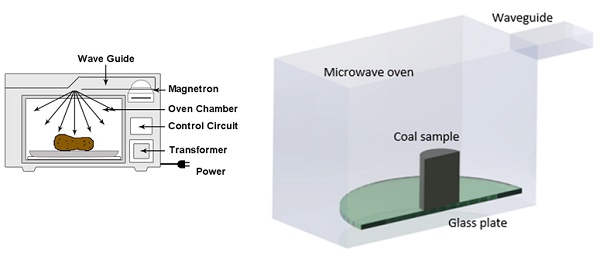

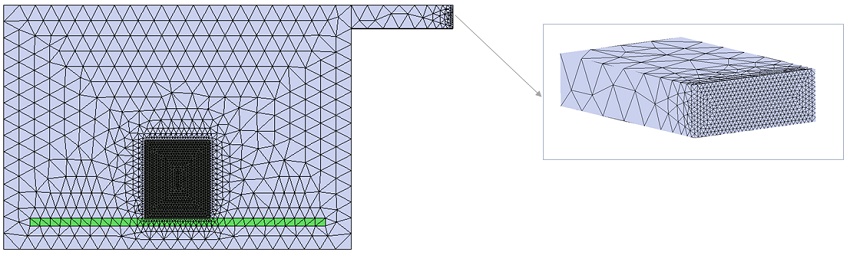

The microwave oven, now a kitchen essential, also offers significant potential for industrial heating applications. Designed to operate at 2.45 GHz, these ovens achieve deeper material penetration and uniform heating. The examined setup includes a rectangular microwave oven, aired and linked to a 2.45 GHz source through a waveguide in TE10 mode, with a glass plate and cylindrical coal sample near its base. Key model parameters and material properties are outlined in Tables 1 and 2. To enhance efficiency, the simulation leveraged a symmetrical half-model approach, depicted in Figure 1.

| Part | Dimension (mm) | |||

| Coal sample | Radius: 25 | Height: 60 | ||

| Glass plate | Radius: 113.5 | Height: 6 | ||

| Microwave oven | Width:267 | Depth:270 | Height:188 | |

| Waveguide | Width:50 | Depth:78 | Height:18 | |

| Material | Relative permittivity | Dielectric loss tangent | Thermal conductivity (W/m. K) |

| Coal | 2.86 | 0.17 | 0.189 |

| Glass | 2.5 | 0 | 0.23 |

| Air | 1 | 0 | 0.024 |

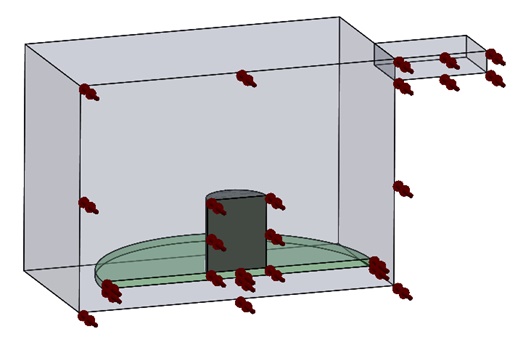

Electromagnetic boundary conditions

The waveguide's entry is equipped with a wave port boundary, designed for transverse electric (TE) waves, and is supplied with 500-Watt power at 2450 MHz. The exterior of the oven and waveguide adopts an Imperfect Electric Conductor (IEC) boundary condition, reflecting copper's conductivity. For the model's vertical symmetry, Perfect Magnetic Conductor (PMC) Symmetry boundaries are applied, streamlining the simulation by focusing on a mirrored segment of the setup.

Mesh

Results

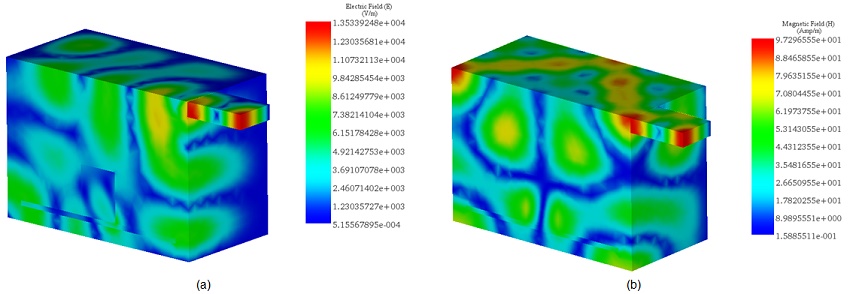

The analysis reveals that the coal sample's absorption of microwave power significantly alters the distribution of electric and magnetic fields in the oven's air space, resulting in an uneven electromagnetic field characterized by areas of both low and high energy. This phenomenon is vividly illustrated in the following figure at 2.45 GHz, showcasing the dynamic energy landscape within the oven.

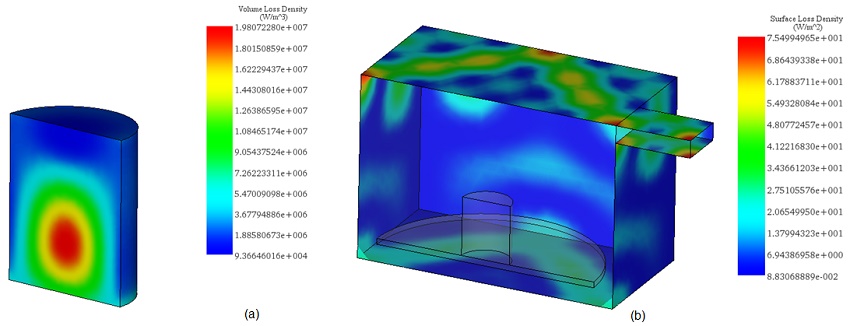

After microwave irradiation, the coal sample heats up due to generated dielectric losses, detailed in Figure 5-a. These losses are negligible in the glass plate and air but are most significant in the sample's center, totaling about 321 Watts or 64.2% of the excitation power.

Conductor losses from the oven's metallic walls, presented in Figure 5-b, are minor in comparison, amounting to only 75 W/m² for a 500-watt input power. This contrast highlights the targeted efficiency of microwave heating in the coal, minimizing waste through the oven's structure.

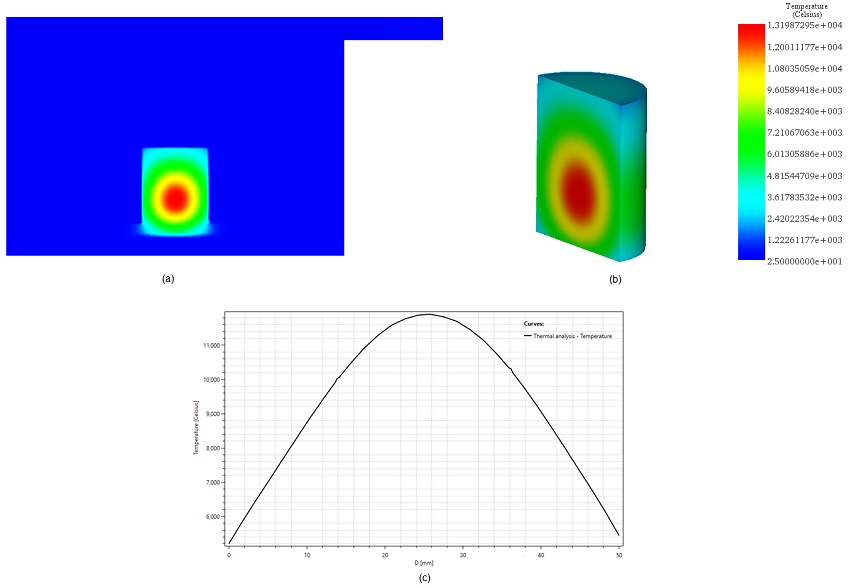

In the steady-state thermal analysis of the microwave heating process, a convection boundary was set around the air cavity, assuming an ambient temperature of 25°C and a convection coefficient of 10 W/m²·°C. This analysis pinpointed that solely the coal sample achieved a peak temperature of around 13,100°C. This outcome emphasizes microwave heating's ability for selective heating, efficiently focusing energy on the target sample and illustrating its suitability for precise thermal applications.

Conclusion

References

[1]. Huang, Jinxin, et al. "Simulation of microwave’s heating effect on coal seam permeability enhancement." International Journal of Mining Science and Technology 29.5 (2019): 785-789.

-Techniques.webp)