EMAG – Low- to Medium-Frequency Electromagnetic Simulation

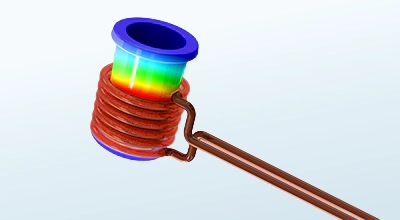

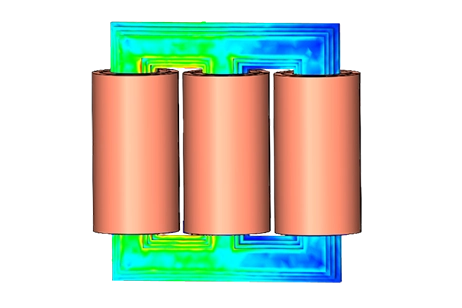

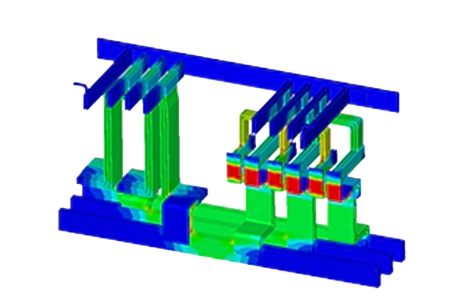

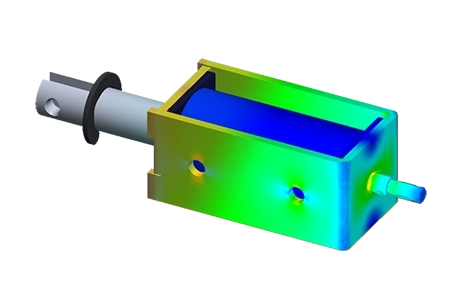

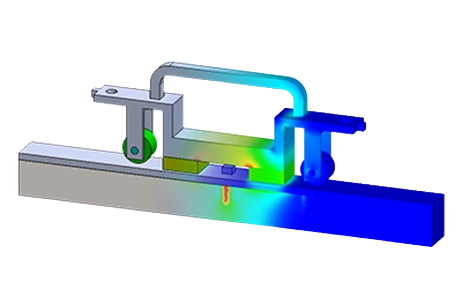

EMAG is the low- to medium-frequency electromagnetic simulation module in EMWORKS. It is used to analyze fields, losses and forces in 2D and 3D models of devices such as electrical machines, actuators, sensors and transformers, in applications across automotive, aerospace, biomedical and power systems.

.webp)

EMAG Overview

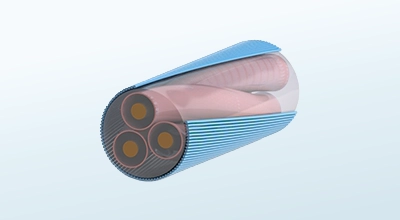

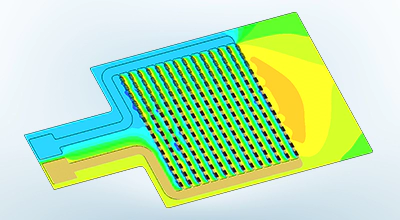

EMAG performs low- to medium-frequency electromagnetic field analysis on 2D and 3D models such as motors, actuators, transformers, and sensors. It handles coils, permanent magnets, conductors, and ferromagnetic parts in full 3D or 2D/axisymmetric setups, with optional parametric sweeps and thermal or structural coupling. Results include fields, flux density, current density, losses, forces, and torques over the geometry for direct comparison of design options.

EMAG Analysis Options

Conduction Analysis

Evaluates steady-state current flow and resistive behavior in conductive materials.

Electrostatic Analysis

Computes electric field distribution under static voltage and charge conditions.

AC Magnetic Analysis

Solves sinusoidal magnetic fields and frequency-dependent electromagnetic effects.

Transient Magnetic Analysis

Analyzes time-varying magnetic fields driven by switching waveforms or pulse excitations.

Start a Free EMAG Trial

Use EMAG to analyze electromagnetic fields, losses, and forces on your 2D and 3D designs with CAD-based workflows.

Multiphysics Coupling

EMAG couples electromagnetic analysis with motion, structural, and thermal solvers for devices where fields interact with mechanics and temperature.

Motion Coupling

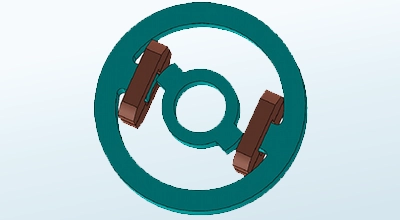

Couple electromagnetic fields with motion to compute force and torque vs position or time in motors, actuators, solenoids, relays and magnetic devices.

Structural Coupling

Map electromagnetic forces and losses to structural and thermo-mechanical analysis to evaluate displacement, stress, strain and safety factors.

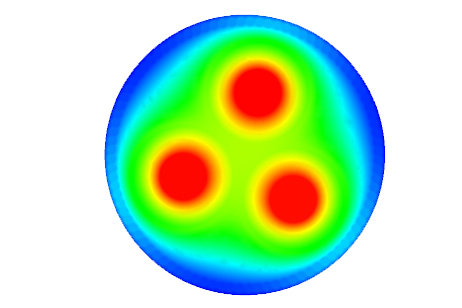

Thermal Coupling

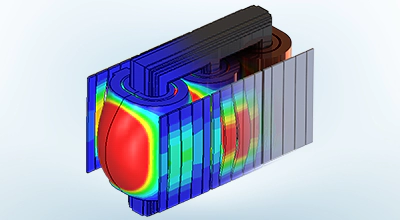

Link electromagnetic losses to steady-state or transient thermal analysis to compute temperature, gradients and heat flux, with optional temperature-dependent EM properties.

.gif)

Circuit Coupling

Circuit Coupling in EMWORKS integrates the 3D electromagnetic model with an electrical schematic. This two-way interaction accurately simulates devices like motors and transformers under transient and steady-state conditions, capturing effects such as back-EMF and saturation.

EMAG Applications

Motors and Generators

Transformers and Inductors

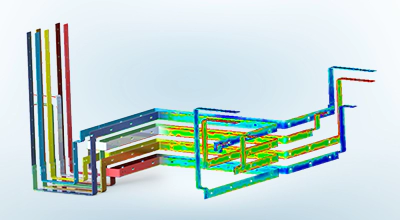

Busbars and Power Distribution

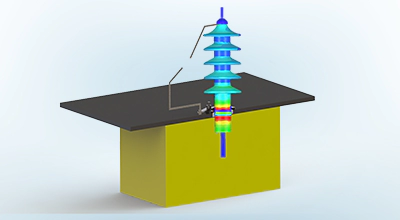

Actuators and Solenoids

Eddy-Current NDT