Why Computational Methods Matter in Engineering

Today’s engineering problems are not only complex—they’re multidimensional. A new motor design involves both electromagnetic and thermal analysis. An antenna must work across frequencies and environments. A medical device may involve electromagnetic exposure, heating, and mechanical stresses all at once.

Analytical equations cannot capture these realities. Instead, engineers rely on computational analysis methods: numerical techniques that break down physical domains into smaller elements, cells, or surfaces that a computer can solve. These methods transform Maxwell’s equations, Navier–Stokes equations, and other governing laws into results engineers can actually use.

For electrical, mechanical, mechatronics, electronic, and design engineers alike, mastering these methods means moving from guesswork to insight.

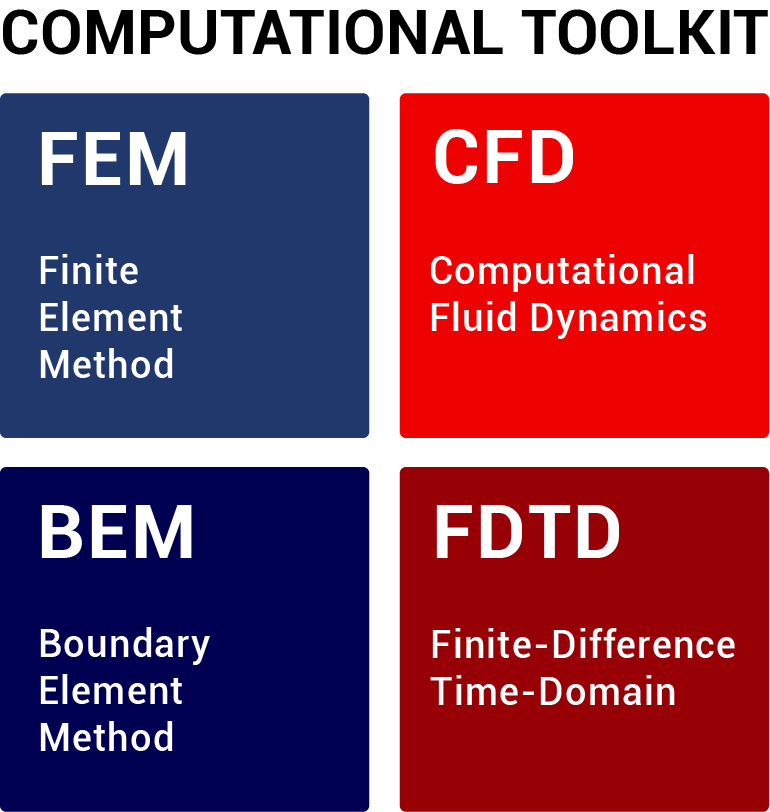

Core Methods Engineers Use

How it works

Why it matters

Example

How it works

Why it matters

Example

How it works

Why it matters

Example

How it works

Why it matters

Example

How it works

Why it matters

Example

Choosing the Right Method - Practical Reference

Application | Best Method | Alternative | Key Considerations |

.png) Static Electric Fields | FEM | BEM | FEM for complex geometries, BEM for infinite domains |

.png) Low-Frequency Magnetics | FEM | - | Nonlinear materials, irregular geometries |

.png) Antenna Design | MoM | FDTD | MoM for narrow-band, FDTD for broadband |

High-Frequency Circuits | FDTD | FEM | FDTD for transients, FEM for steady-state |

Thermal Management | CFD | FEM | CFD for fluid cooling, FEM for conduction |

EMI/EMC | MoM / FDTD | FEM | Depends on frequency and geometry |

Power Systems | FEM | BEM | FEM for equipment, BEM for grounding |

This matrix is a guide, not a rulebook. In practice, engineers often combine methods—for example, using FEM for a motor’s electromagnetic fields, then CFD for its cooling system.

Beyond the Matrix - Factors That Shape Your Choice

Accuracy Needs

FEM and FDTD can deliver highly accurate results, but they often require more computational time. The right balance depends on how precise your design must be versus how quickly you need results.

Geometry Complexity

Irregular or nonlinear geometries typically favor FEM. For problems in infinite domains, BEM can provide cleaner results with fewer resources.

Computation Time

MoM can solve open-radiation problems faster than FEM, while CFD is resource-heavy but essential for cooling analysis.

Data Type

If you need steady-state solutions, FEM is often preferred. For transient or broadband results, FDTD captures the physics more naturally.

Workflow and Toolchain

The best method is not just the most accurate one—it’s also the one that fits into your team’s workflow and available tools.

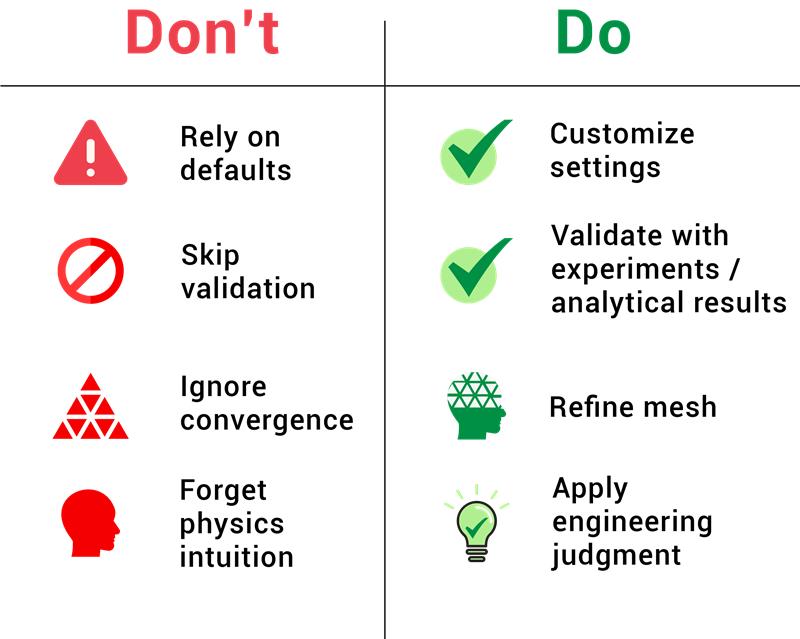

Common Pitfalls and Mistakes to Avoid

Relying on defaults can be dangerous. Automatic mesh generation and default boundary conditions rarely capture every important aspect of a problem.

Skipping validation often leads to overconfidence in results. Whenever possible, compare simulations with analytical solutions or experimental data.

Ignoring convergence is a common trap. A coarse mesh might run quickly but produce misleading results. Always refine until results stabilize.

Forgetting physics intuition may result in beautiful plots that make no physical sense. Ask yourself: Do these results align with fundamental engineering expectations?

Applications Across Industries

Electric Motors (FEM + CFD)

Used to predict torque, efficiency, losses, and cooling performance in designs such as PMSMs.

Wireless Power Transfer (FEM + MoM)

Helps evaluate coil coupling efficiency and assess potential radiation leakage.

Medical Devices (FEM + FDTD)

Simulates electromagnetic exposure and heating effects in tissues and implants.

Induction Heating (FEM + CFD)

Analyzes magnetic fields and resulting thermal distributions in industrial processes.

Sensors (FEM + BEM)

Optimizes magnetic and electromagnetic sensors for accuracy and durability in harsh environments.

Practical Tips for Getting Started

- Start simple — begin with 2D problems before attempting full 3D models.

- Validate your results — compare with hand calculations or experiments whenever possible.

- Refine your mesh — keep testing until results stabilize.

- Plan for resources — estimate computation time and memory before committing to large runs.

- Trust your intuition — remember that simulation is a tool, not a replacement for engineering judgment.

Building Your Engineering Toolkit

No single method solves every problem. The most effective engineers learn to combine FEM, CFD, MoM, BEM, and FDTD depending on context. The real advantage lies in knowing which tool matches which physics and applying them with confidence.

EMWORKS brings these methods together in one accessible platform, so engineers can focus on solving real problems—from motors and sensors to antennas and power systems—without wasting time switching tools.

Computational methods are not replacements for engineering intuition—they are amplifiers of it. By starting simple, avoiding common mistakes, and gradually building skill, you can make smarter design choices, reduce risks, and accelerate innovation.

In the end, the best method is the one that gives you trustworthy results, within your time and resource limits, for the problem you actually face.