Transformers are the backbone of modern power systems, enabling electricity to be transmitted over long distances and distributed at usable voltage levels. From high-capacity power transformers in transmission networks to compact units in electronics, their role is fundamental.

As energy efficiency and sustainability continue to dominate engineering priorities, improving transformer performance is no longer optional. Even a small gain in efficiency, when applied across thousands of units in service, translates into significant energy savings and cost reductions over decades of operation.

Understanding Transformer Efficiency

Transformer efficiency measures how effectively input power is converted into output power. It is calculated as:

\( \eta = \frac{P_{out}}{P_{in}} \times 100\% \)

A more practical formula includes losses:

\[\eta = \frac{P_{out}}{P_{out} + P_{losses}} \times 100\%\]

Modern industrial transformers achieve efficiencies between 95% and 99.5%, with larger units tending toward the higher end. The difference may seem small, but over a transformer’s lifetime, even a 1% loss compounds into major financial and energy costs.

What Influences Transformer Efficiency?

Losses in transformers can be grouped into two main categories:

Core (Iron) Losses

- Hysteresis Losses – Energy wasted during cyclic magnetization of the core.

- Eddy Current Losses – Circulating currents induced in the core, dissipating heat.

Copper (Winding) Losses

- I²R Losses – Resistive heating in windings.

- Stray Load Losses – Additional losses from leakage flux interacting with structural parts.

Additional Factors

Operating temperature, load variation, frequency changes, material quality, and long-term maintenance all affect real-world efficiency.

Methods to Improve Transformer Efficiency

Core Material Optimization

High-grade silicon steel or amorphous alloys reduce hysteresis and eddy current losses; nanocrystalline options push this further when budgets allow.

Winding Design Improvements

Larger conductors minimize I2R losses ; transposition smooths current distribution; geometry choices reduce stray flux.

Cooling System Enhancement

Air or liquid cooling systems stabilize temperatures and extend efficiency; improved heat exchangers extend service life.

Load Management

Transformers should operate near their design load point. If demand swings, utilities often switch units in or out to keep each within its optimal band.

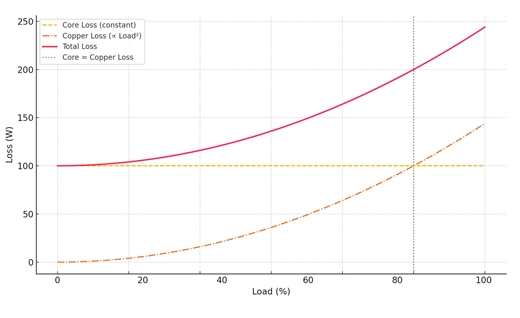

The Impact of Load on Total Efficiency - Finding the Sweet Spot

Transformer efficiency is not constant — it changes with load because:

\[P_{losses} = P_{core} + P_{cu}\]

- Light Load (10–20%) – Copper losses are minimal, but fixed core losses dominate → lower efficiency.

- Heavy Load (near 100%) – Output is high, but copper losses rise sharply, again lowering efficiency.

Point of Maximum Efficiency occurs when copper losses equal core losses.

This balance is a critical design consideration, since it determines the load range at which the transformer will operate most economically over its decades-long lifetime. Distribution transformers, for example, are often designed to peak at 50–70% of full load, reflecting their typical duty cycle.

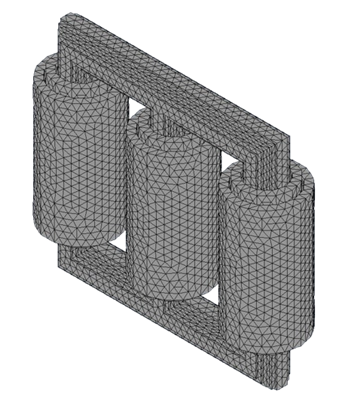

The Role of Finite Element Analysis in Transformer Design

Traditional design methods struggle to balance materials, winding layout, cooling, and load profiles. This is where Finite Element Analysis (FEA) becomes indispensable.

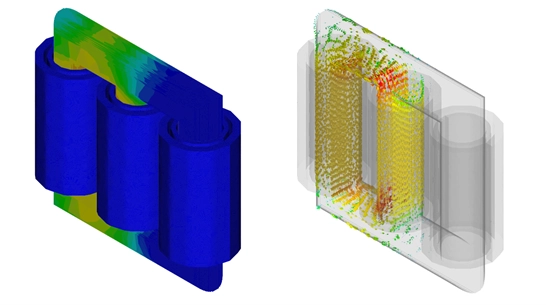

What FEA Offers Engineers

- Visualization of magnetic flux distribution.

- Loss calculation under different materials and geometries.

- Thermal analysis to test cooling strategies.

- Mechanical stress and insulation behavior.

With simulation, engineers can validate designs before committing to prototypes, reducing development costs and accelerating time to market.

Why Use Simulation Tools Like EMWORKS EMAG?

Simulation tools provide a virtual testbed to:

- Compare core and winding materials.

- Evaluate cooling methods under realistic duty cycles.

- Pinpoint the load range where efficiency peaks.

- Reduce prototyping costs and development time.

By modeling different load cases before committing to production, engineers gain confidence that designs will remain efficient and reliable across the transformer’s lifetime.

Design Implications & Next Steps

Improving transformer efficiency is ultimately a design-load problem: the goal is to align copper and core losses in the range where the transformer will spend most of its service life. Simulation with EMWORKS EMAG helps engineers test materials, winding strategies, and cooling systems early in the process, reducing risk and enabling cost-effective designs.