Introduction

Material selection has a direct impact on the performance of DC solenoids and electromagnetic actuators. The magnetic properties of the core, housing, and plunger determine how much flux the coil can generate and how much force the solenoid can produce. This application note evaluates how six different magnetic materials influence the plunger force in a DC solenoid actuator.

This study compares low-carbon steels, free-machining steels, electrical steels, and soft‑magnetic composites using the same geometry, same excitation, and identical boundary conditions. The results show how permeability, saturation flux density, and B–H curve shape affect solenoid force.

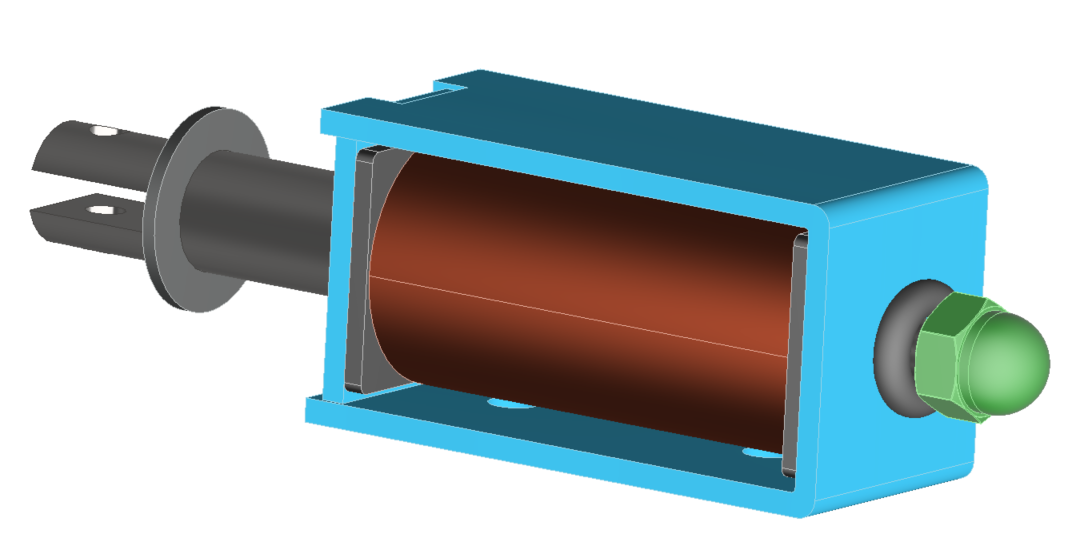

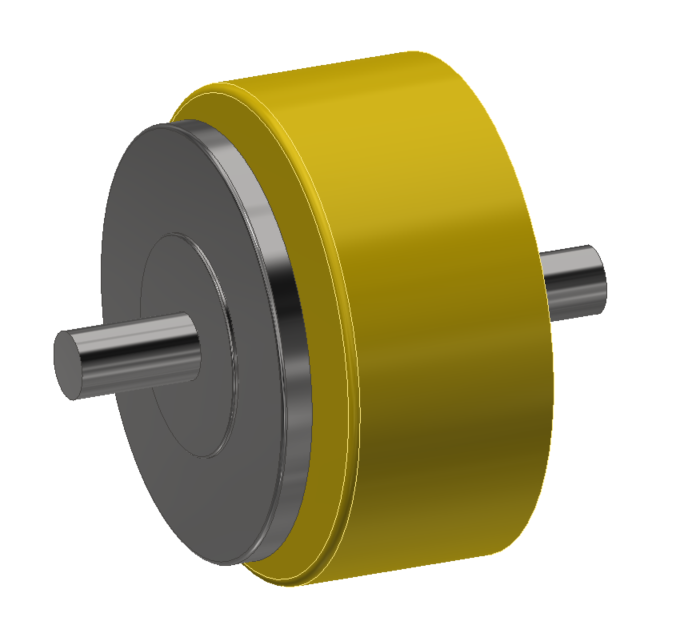

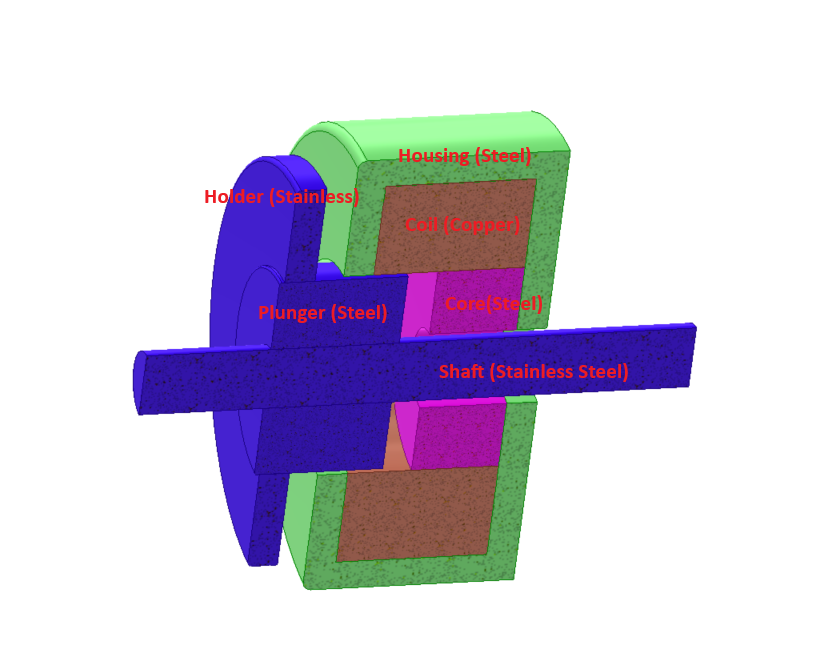

Model Setup

The solenoid includes a copper coil, a steel core, a steel plunger, and a steel housing. The shaft and front holder are stainless steel and do not carry magnetic flux.

Coil excitation:

- DC voltage: 33 V

- Turns: 432

- Wire gauge: AWG 23 copper

- Coil DC Resistance = 3.586 Ohms

- Steady‑state current: I = 9.202 A

- Magnetomotive force: NI = 432 × I = 3975.84 At;

Only the magnetic material of the core, plunger, and housing is changed between cases.

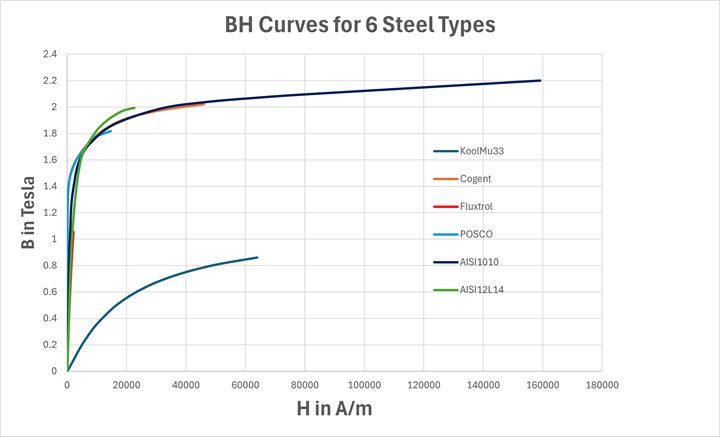

Magnetic Materials and B–H Curves

Six materials were evaluated:

- AISI 12L14

- AISI 1010

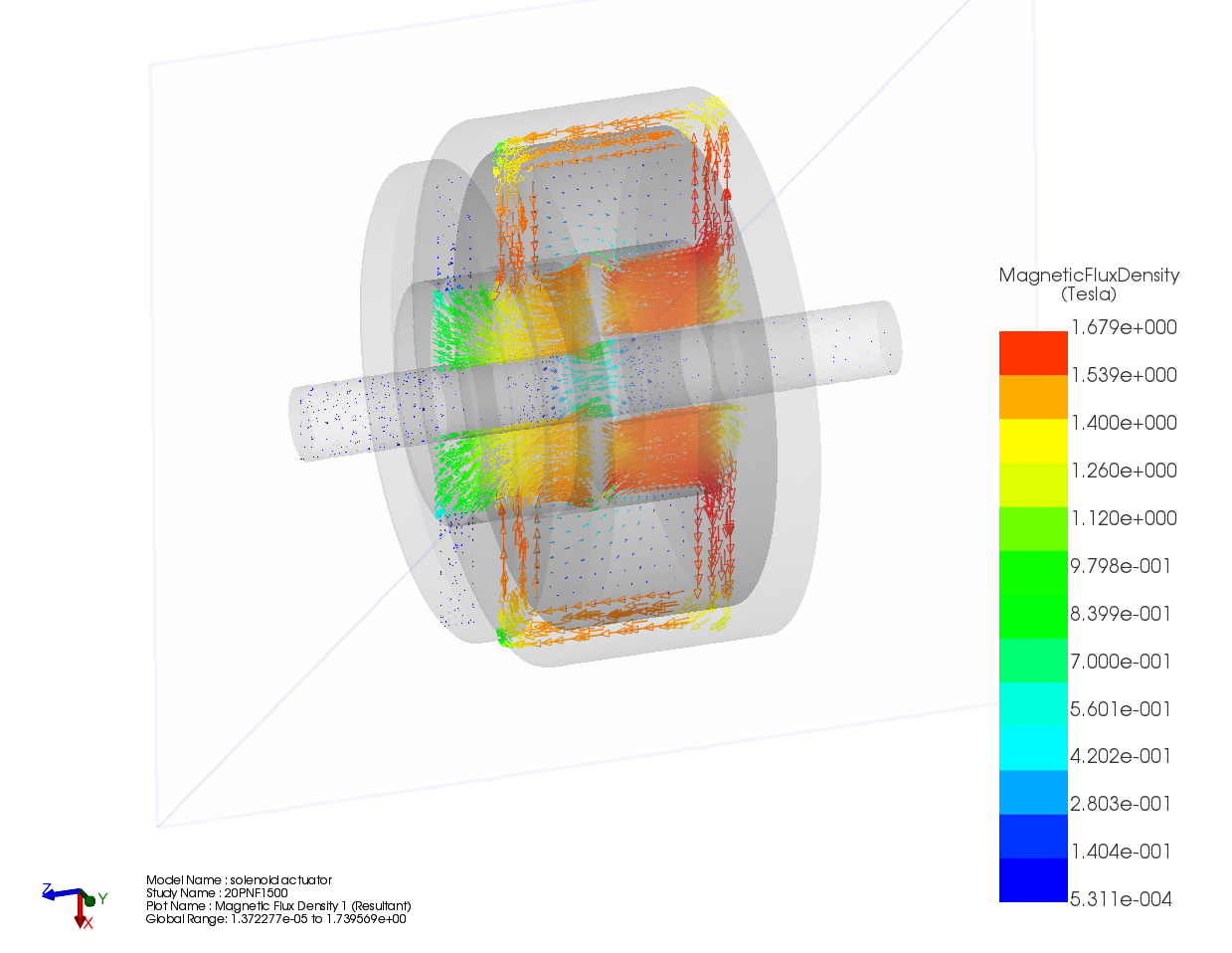

- 20PNF1500 electrical steel made by POSCO

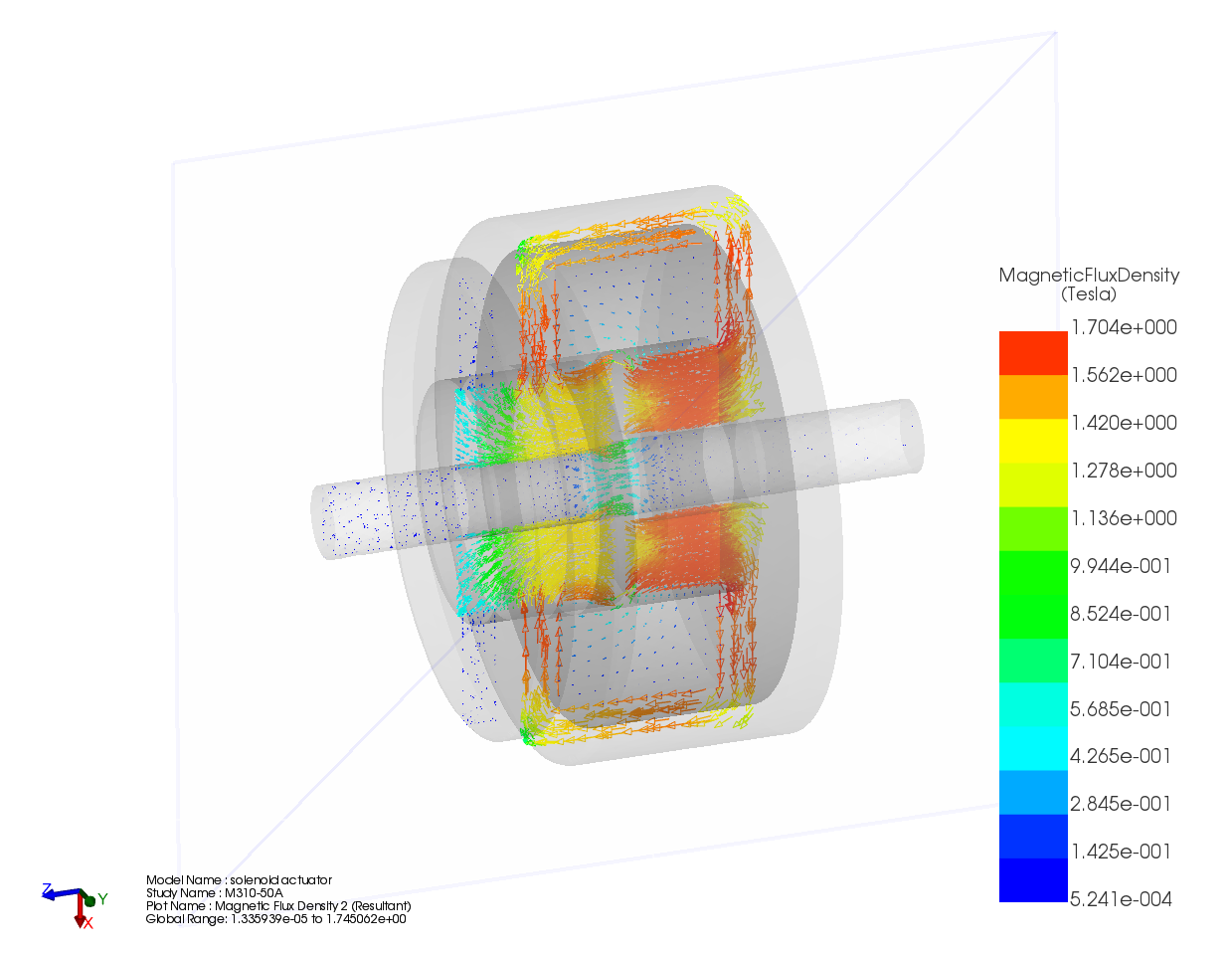

- M310‑50A electrical steel made by Cogent

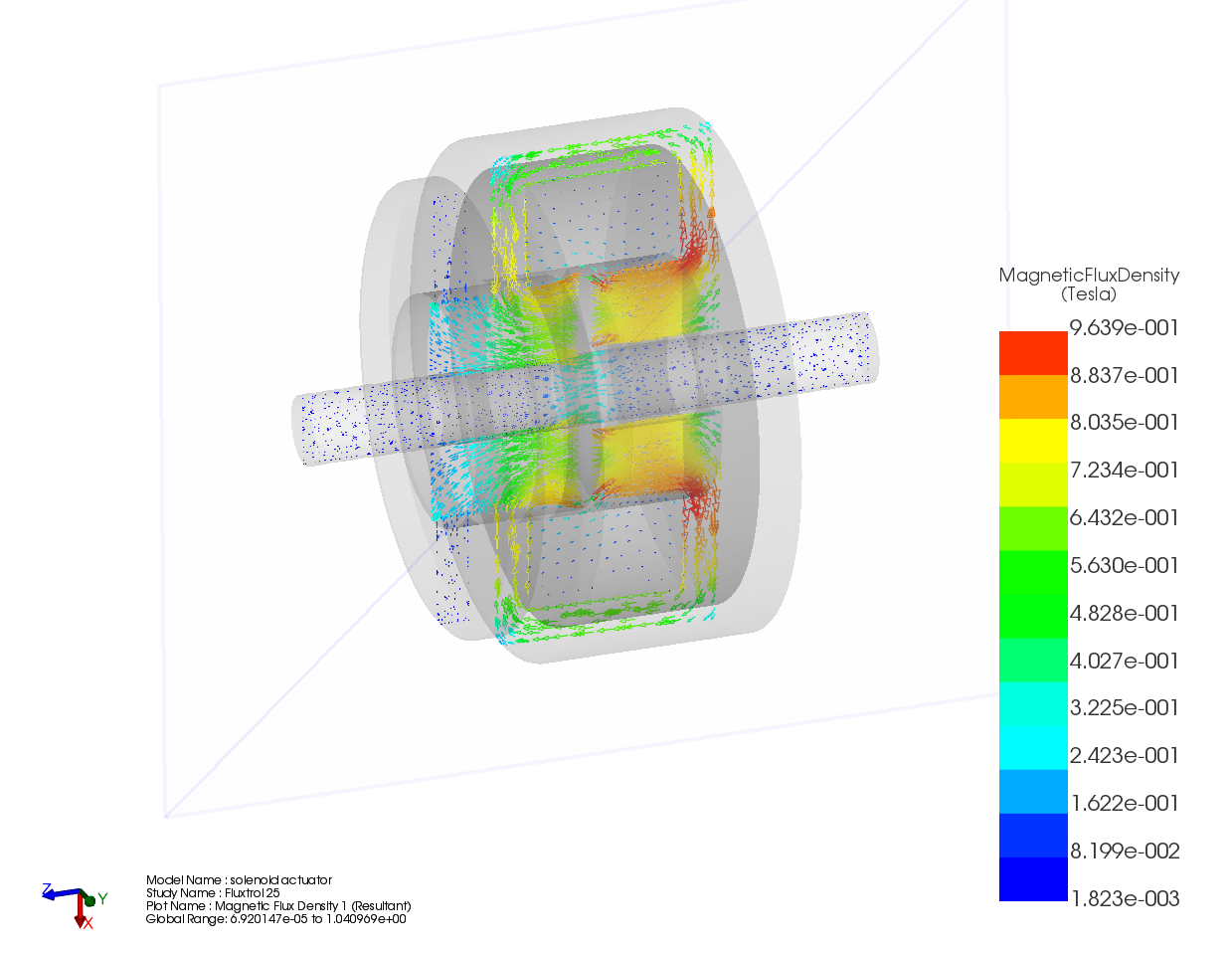

- Fluxtrol 25 made by Fluxtrol

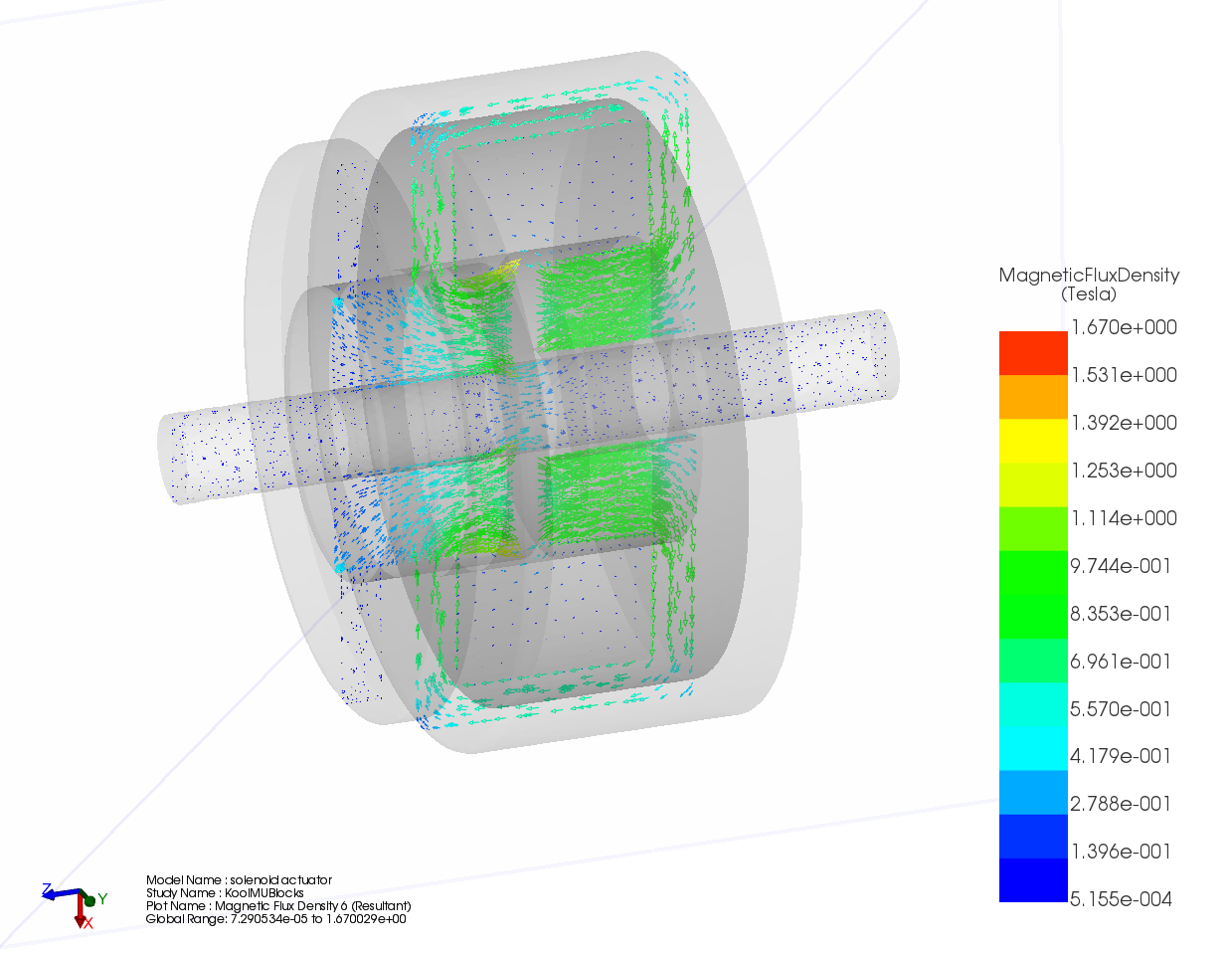

- KoolMuBlocks 33µ made by Magnetics

Simulation Procedure

All simulations were solved as steady‑state magnetostatic problems. Only the magnetic material changed—geometry, NI, and boundary conditions remained identical.

Plunger force was computed using the Virtual Work force method.

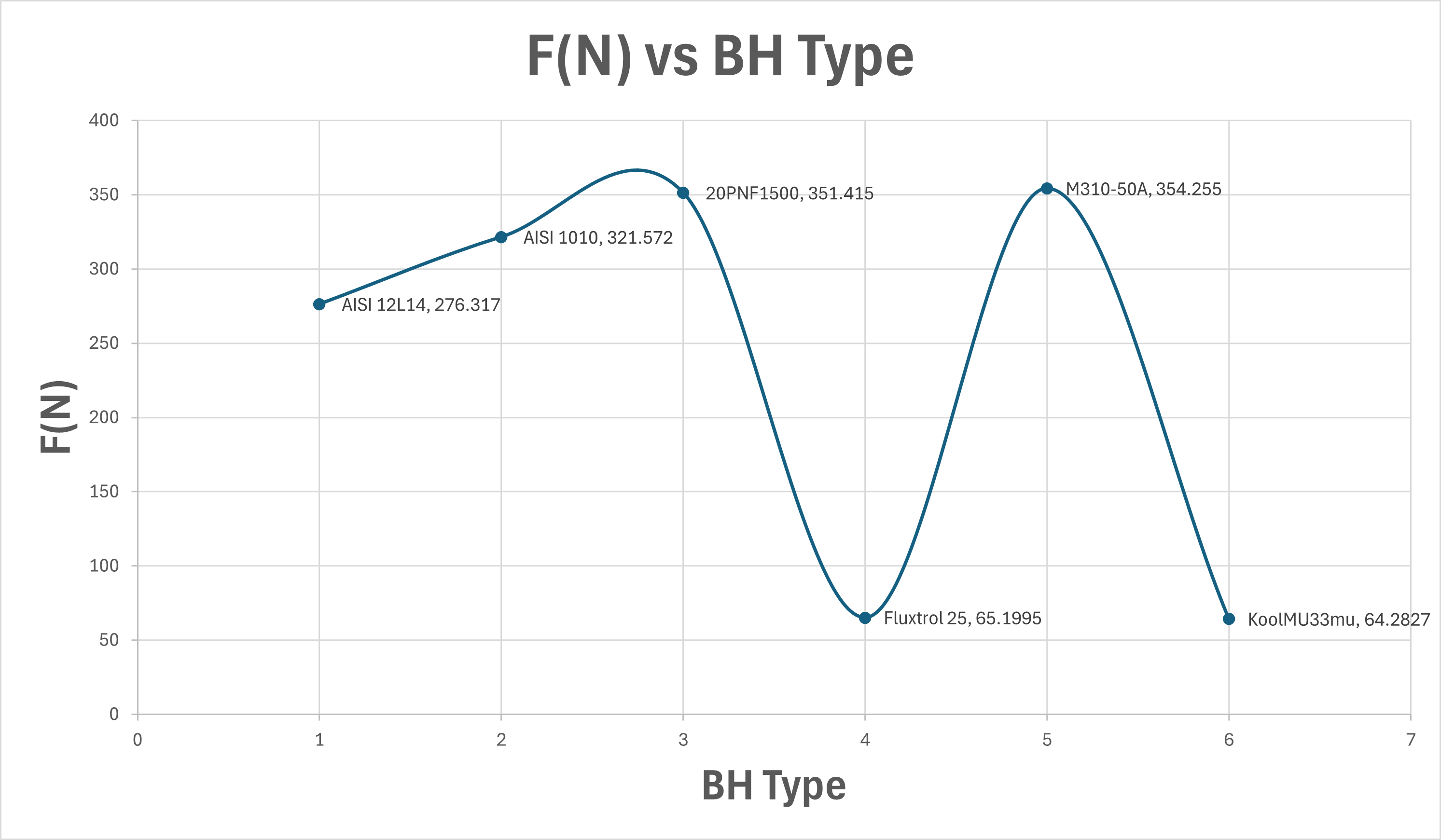

Plunger Force Comparison

Force Results:

- AISI 12L14 — 276.317 N

- AISI 1010 — 321.572 N

- 20PNF1500 — 351.415 N

- M310‑50A — 354.255 N

- Fluxtrol 25 — 65.200 N

- KoolMu 33µ — 64.283 N

Electrical steels provide the highest force. Low‑carbon steel is intermediate. Free‑machining steel and soft magnetic composites produce much lower force.

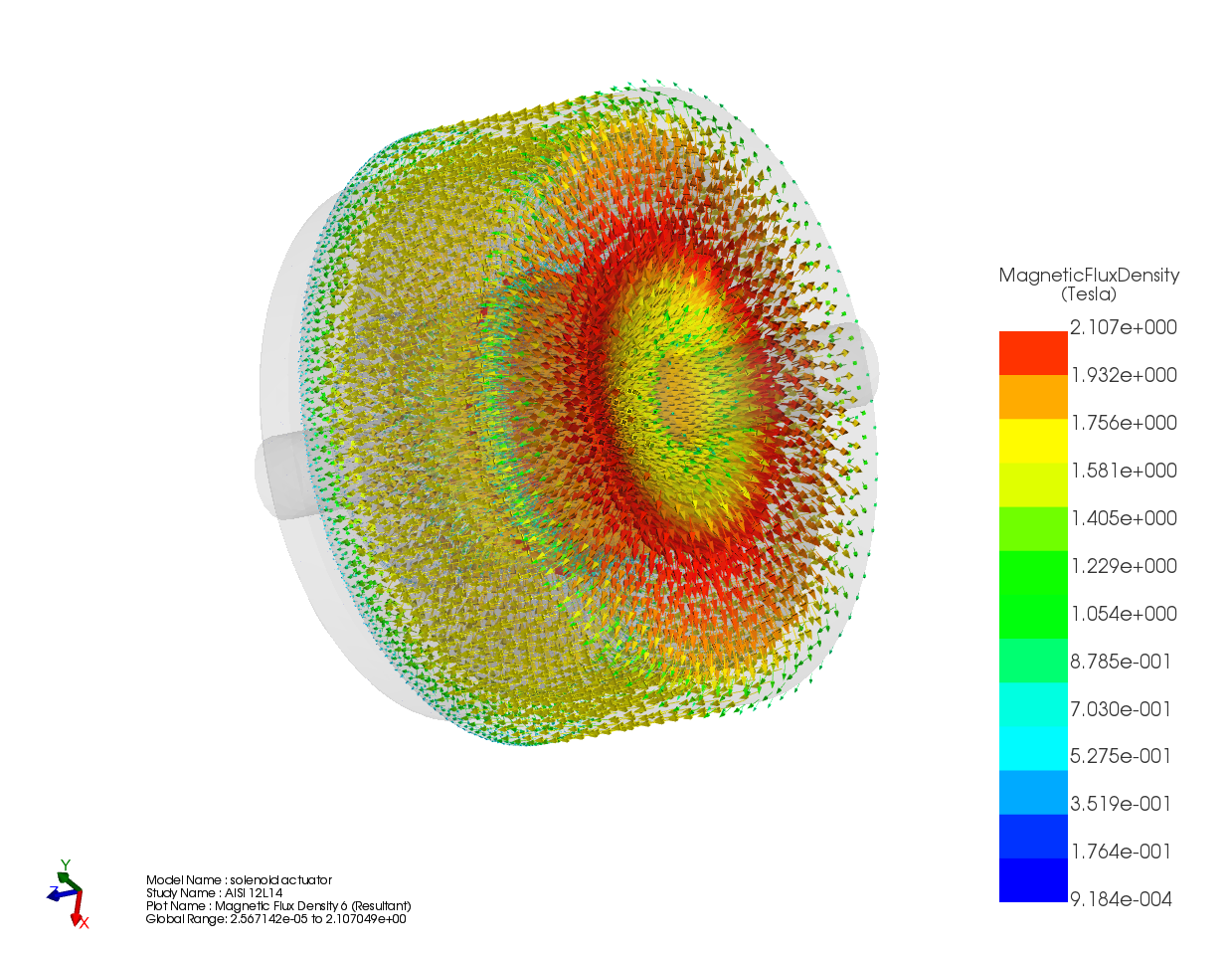

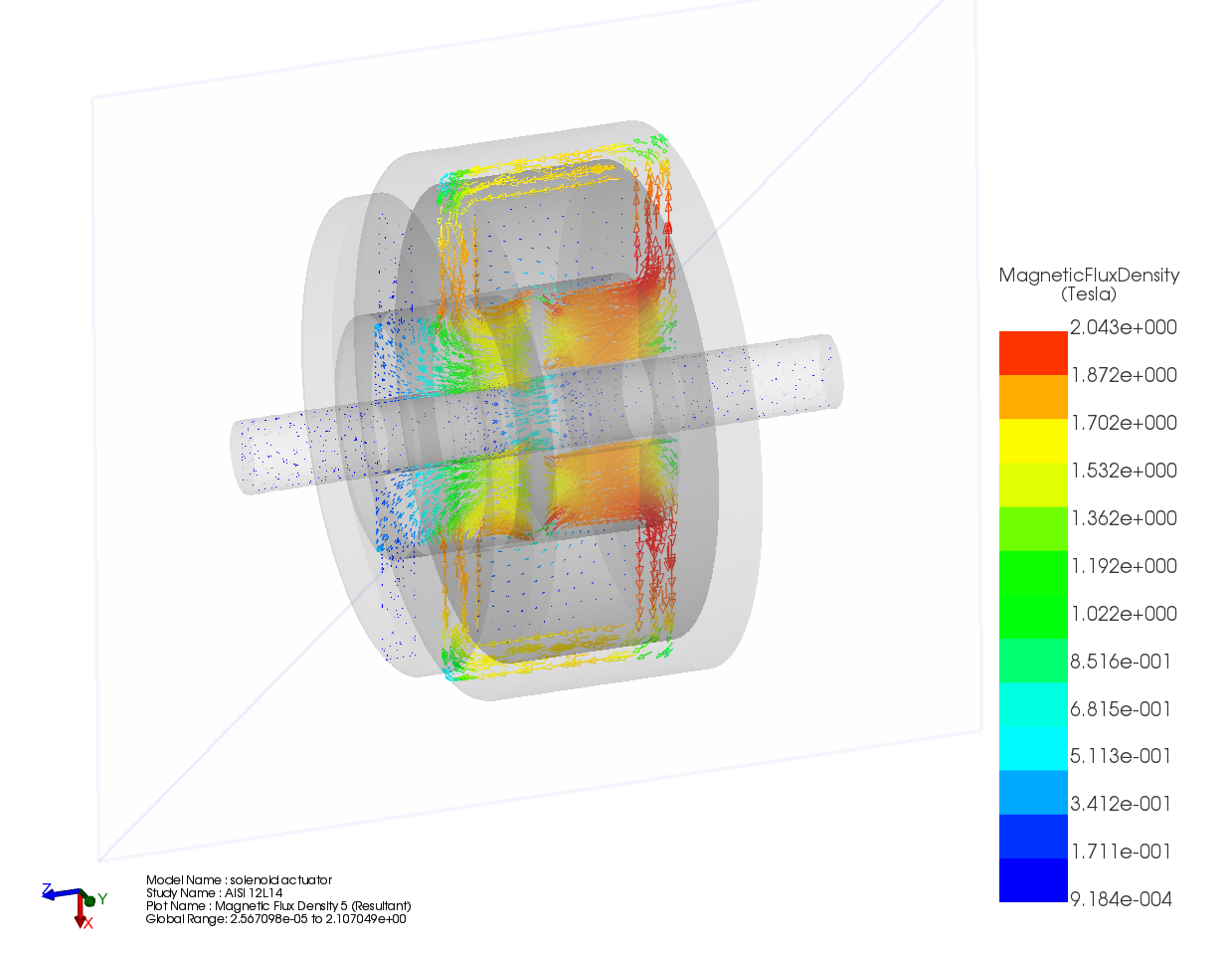

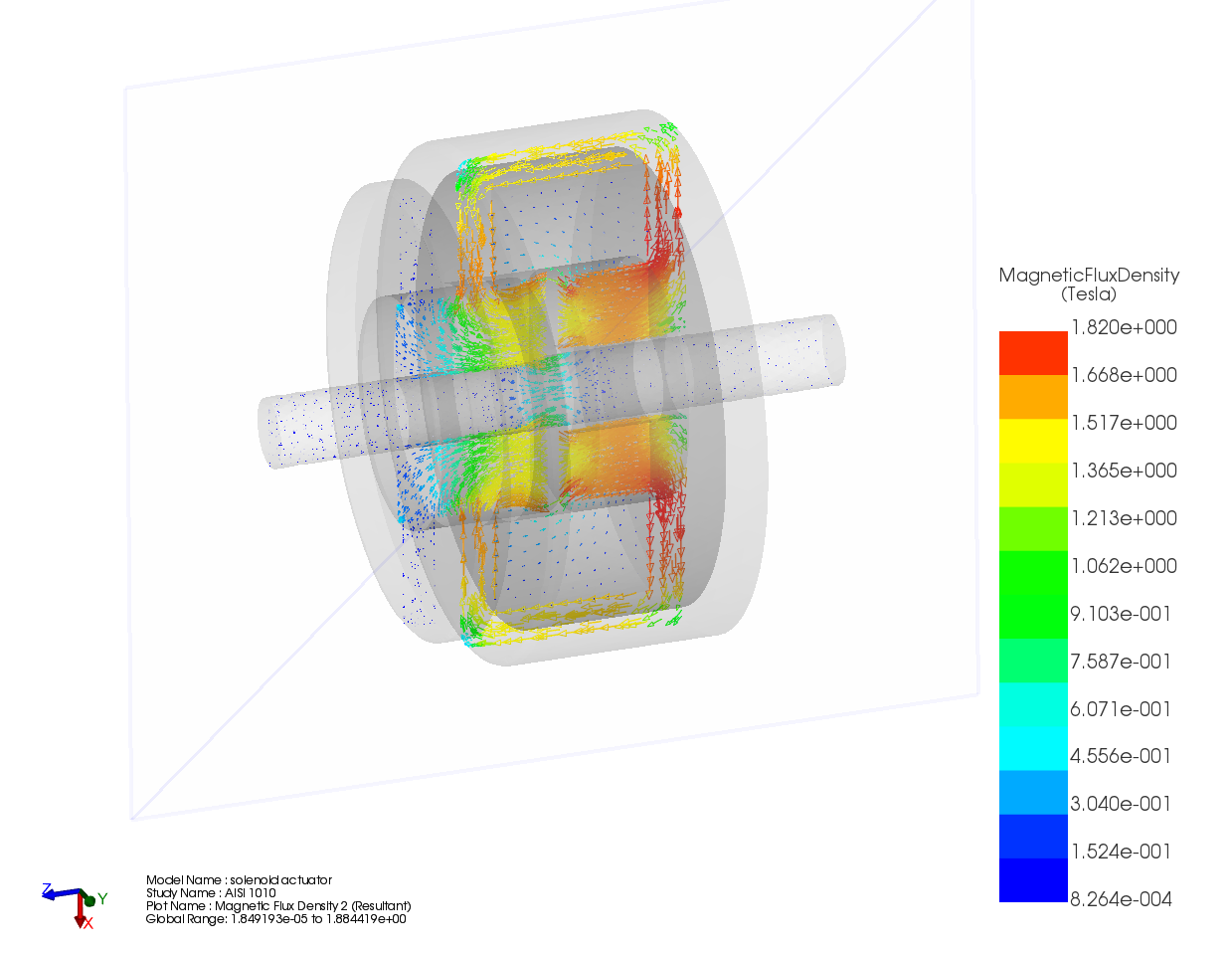

Flux Distribution

Electrical steels produce the highest and most concentrated flux in the air gap. AISI 1010 shows slightly lower flux. AISI 12L14 shows earlier saturation. Fluxtrol 25 and KoolMu 33µ produce low and diffuse flux patterns, which reduces force.

Discussion

High permeability and high saturation directly increase air‑gap flux and plunger force.

- Electrical steels → highest performance

- AISI 1010 → good practical choice

- AISI 12L14 → avoid for magnetic circuits

- Soft magnetic composites → not suitable for DC solenoids requiring high force

Conclusion

Material selection has a direct impact on DC solenoid performance. In this study, the plunger force varied by almost a factor of five depending on the magnetic material used for the core, plunger, and housing. Electrical steels such as 20PNF1500 and M310-50A produced the highest force due to their high permeability and high saturation levels. Low-carbon steel (AISI 1010) provided good performance at lower cost. Free-machining steel (AISI 12L14) showed reduced force, and soft magnetic composites such as Fluxtrol 25 and KoolMu 33µ produced very low force under DC excitation.

All computations were performed using EMWORKS – EMAG, with identical geometry, excitation, and boundary conditions for each material case. The results demonstrate how B–H curve characteristics directly govern flux levels and force output in DC solenoid actuators.