Introduction

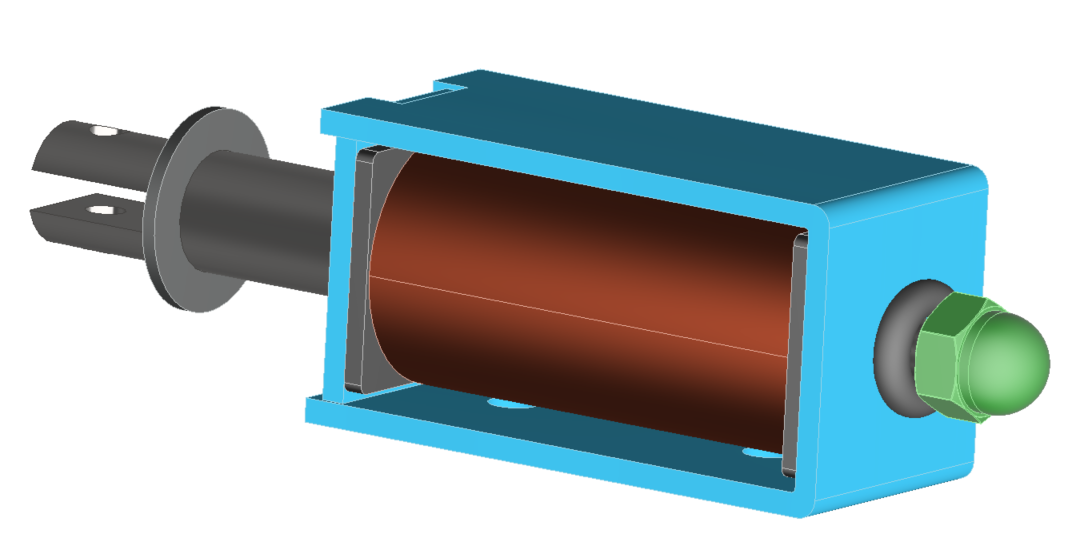

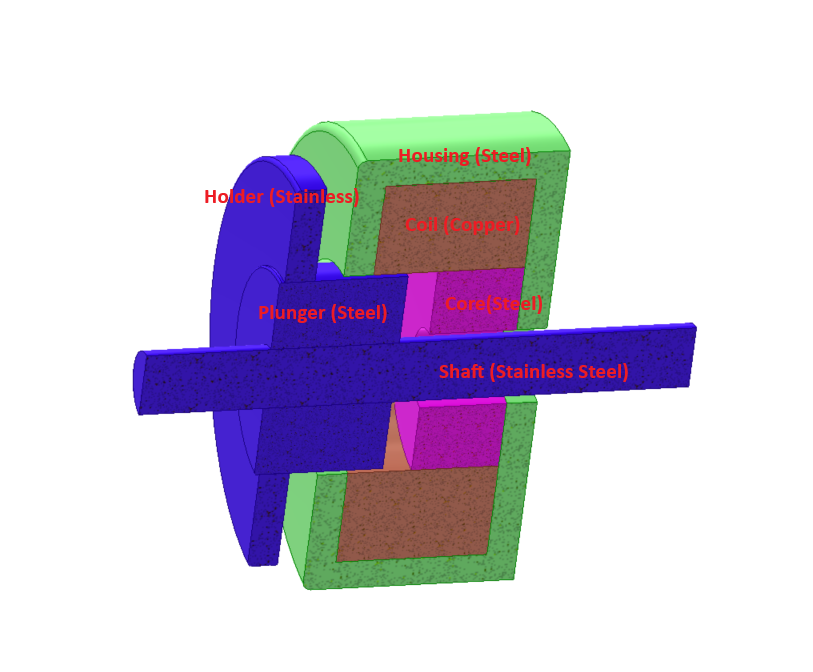

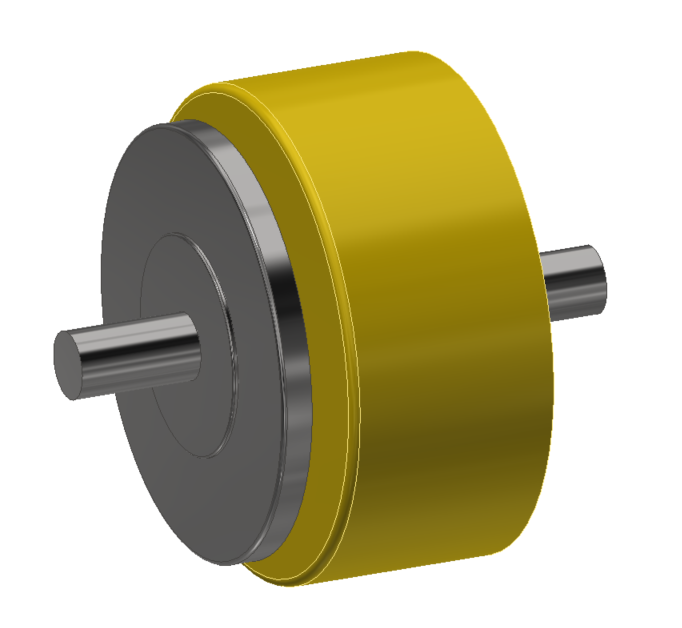

The performance of a DC solenoid depends strongly on coil design. The number of turns, wire gauge, resistance, and current determine the ampere-turns, magnetic energy, and force acting on the plunger. To isolate coil effects, the solenoid geometry and all magnetic parts (core, plunger, housing) use AISI 1010 steel. The filling factor remains nearly constant across designs, meaning each coil contains approximately the same amount of copper. All simulations were performed using EMWorks EMAG.

Model Setup

Magnetic components:

- Core, housing, plunger: AISI 1010 steel

- Shaft and holder: Stainless steel

- Coil: Copper, same geometric winding window for all configurations

Excitation:

- DC voltage: 33 V

- Magnetostatic steady-state solution

Coil Designs:

| AWG | Wire Diameter (mm) | Turns | Filling Factor |

| 30 | 0.2345 | 2582 | 0.5162 |

| 23 | 0.5733 | 432 | 0.5162 |

| 20 | 0.8118 | 215 | 0.5151 |

Table 1: Coil Configurations

Simulation Quantities

EMAG computes for each coil:

- Resistance R, Current I, Ampere-turns NI, Inductance L,

- Flux linkage λ = LI, Magnetic energy W = 1/2 L I²,

- Plunger force F, Copper loss P = R I².

Results

| AWG | Energy (J) | Force (N) | Resistance (Ω) | Inductance (H) | Flux Linkage (Wb·t) | NI (A·turns) | Current (A) | Copper Loss (W) |

| 30 | 0.075 | 13.53 | 108.635 | 1.5796 | 0.4798 | 784 | 0.304 | 10.02 |

| 23 | 1.769 | 321.57 | 3.5857 | 0.03910 | 0.3598 | 3976 | 9.203 | 303.71 |

| 20 | 3.150 | 486.68 | 0.8900 | 0.00411 | 0.1524 | 7972 | 37.08 | 1223.54 |

Table 2: Full solenoid results for all three coil configurations

Discussion

Force and Ampere-Turns:

Force trends follow NI and saturation behavior. AWG 23 provides strong force with manageable heating.

AWG 20 maximizes force but has extreme heating. AWG 30 produces negligible force.

Copper Loss and Thermal Limits:

Heating is proportional to R I². AWG 30 has minimal heating; AWG 23 moderate; AWG 20 exceeds 1.2 kW, making steady DC operation impractical.

Inductance and Flux Linkage:

Inductance correlates with N². AWG 30 shows highest inductance but low current → low magnetic output. Flux linkage does not correlate directly with force under DC excitation.

Magnetic Energy:

Energy follows W = 1/2 L I². AWG 23 and AWG 20 generate significant magnetic energy, consistent with force results. AWG 30 stores too little energy for practical actuation.

Filling Factor Significance:

Nearly identical fill factors ensure each coil uses the same copper mass. Performance differences arise solely from electrical and magnetic effects, not geometry.

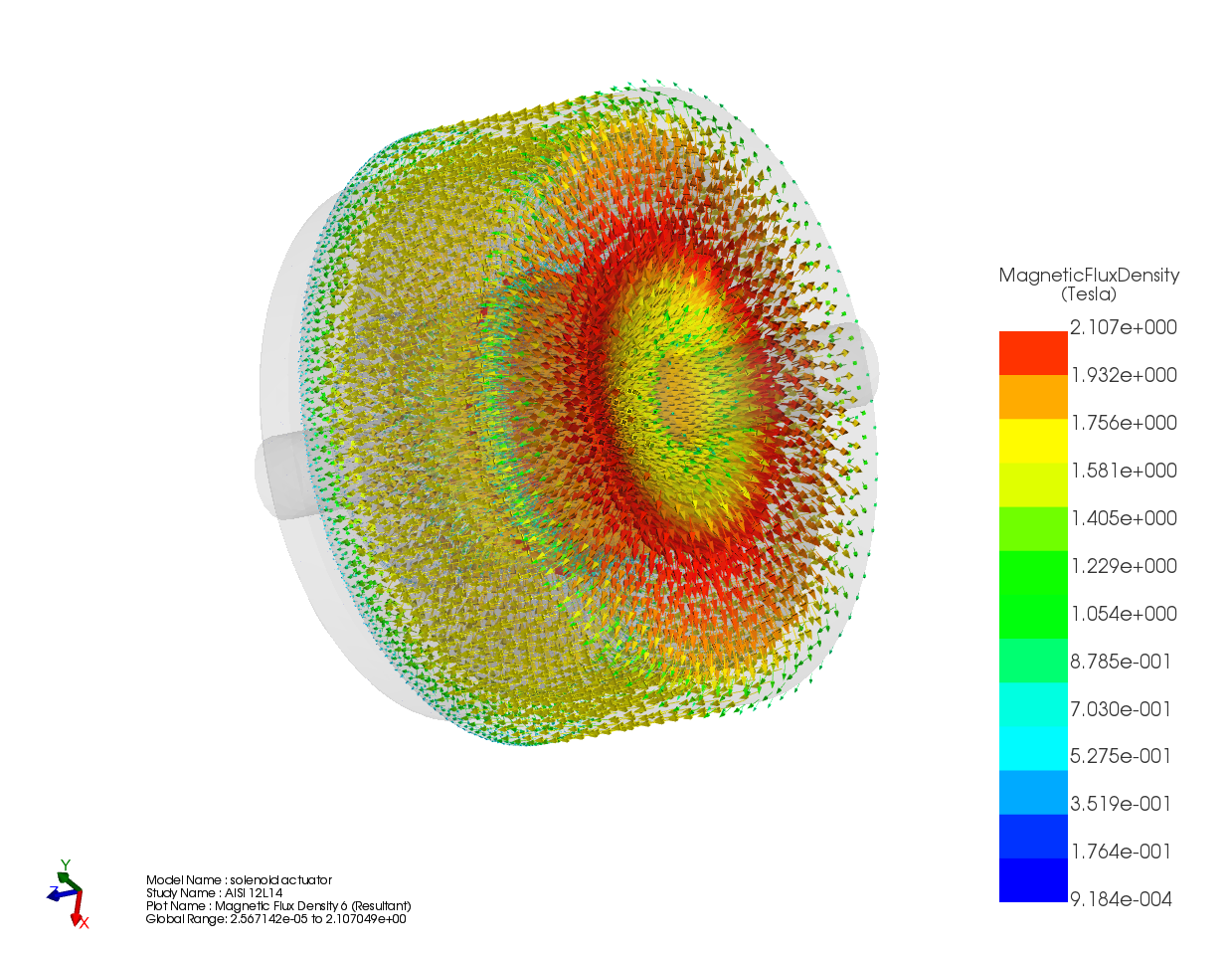

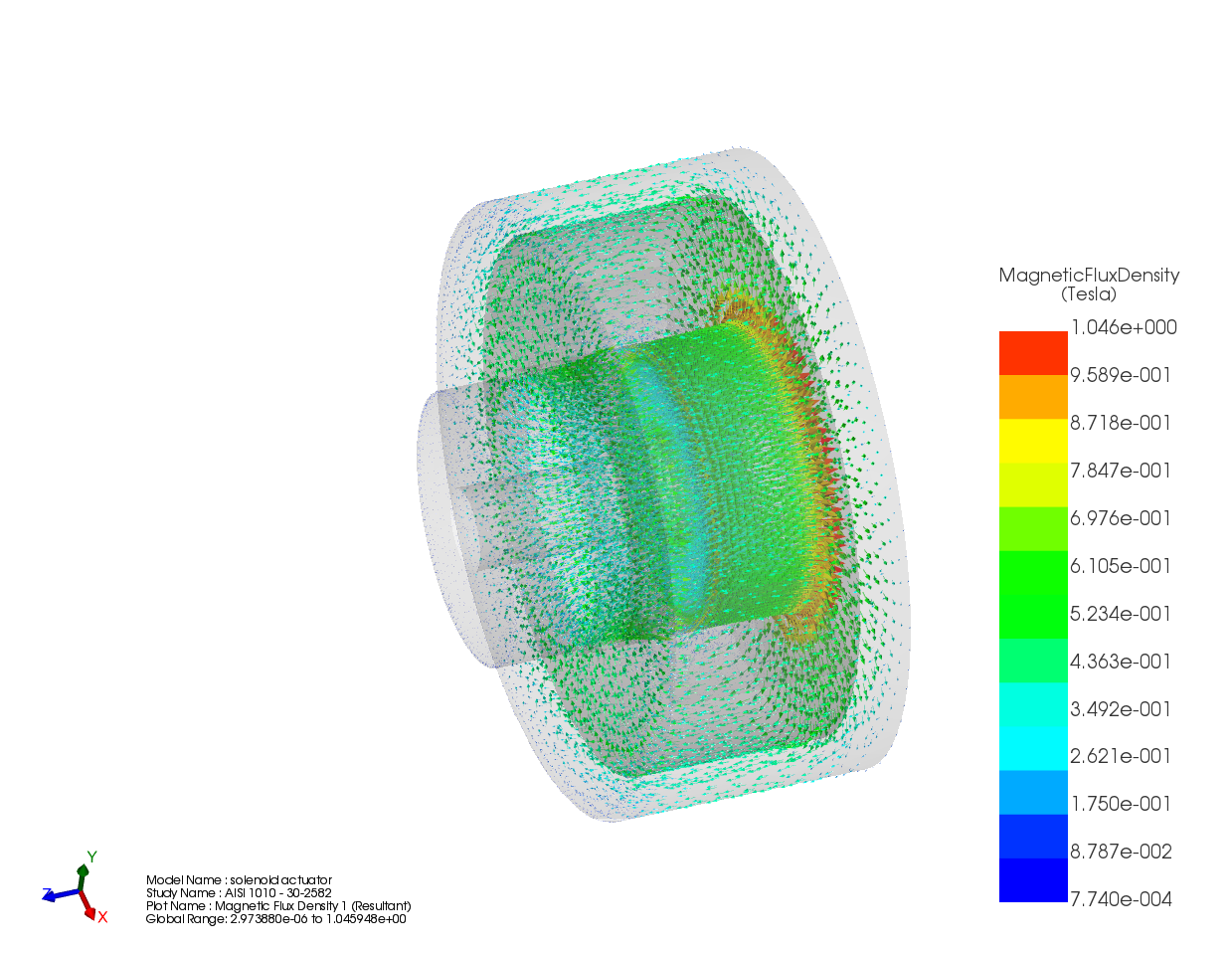

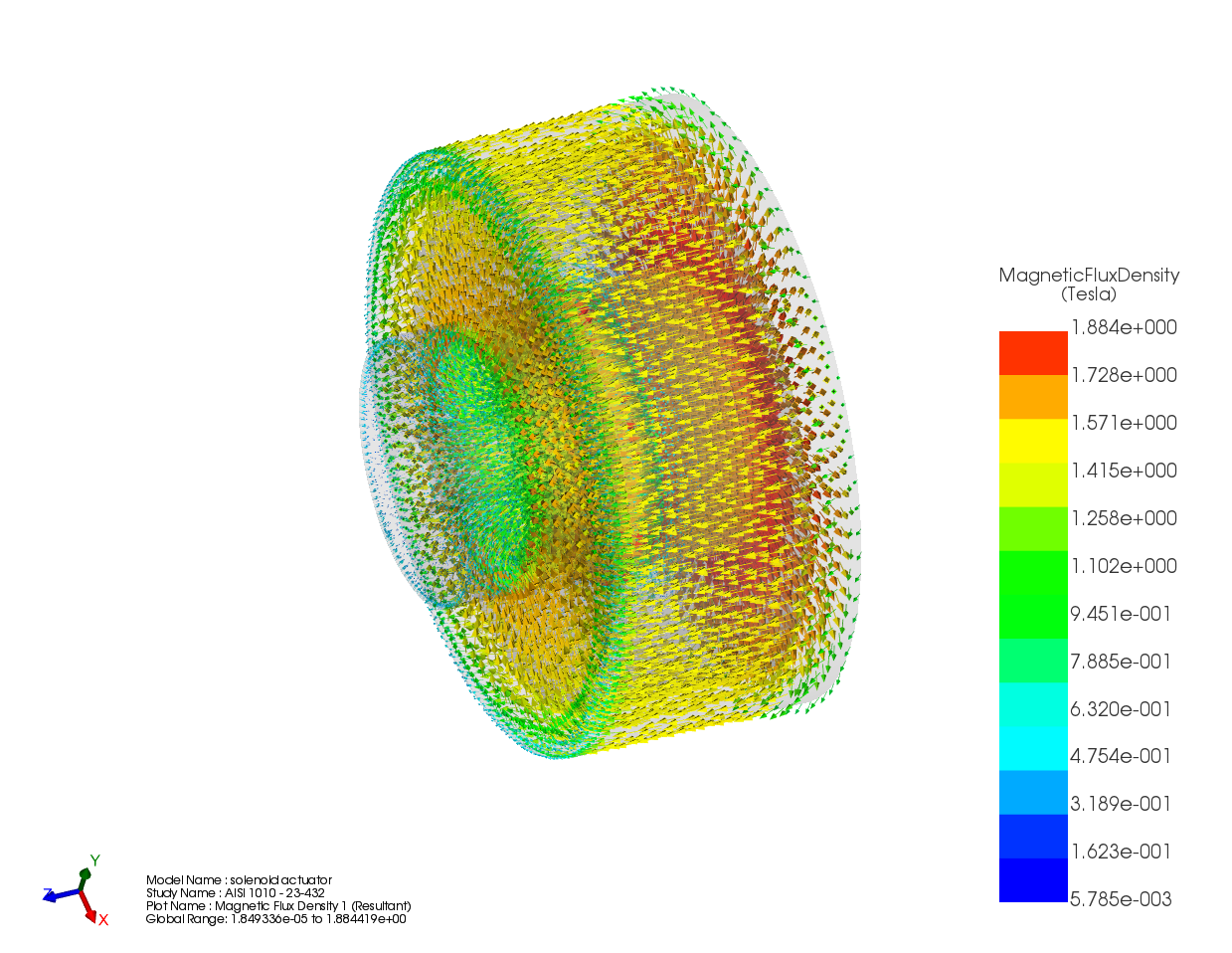

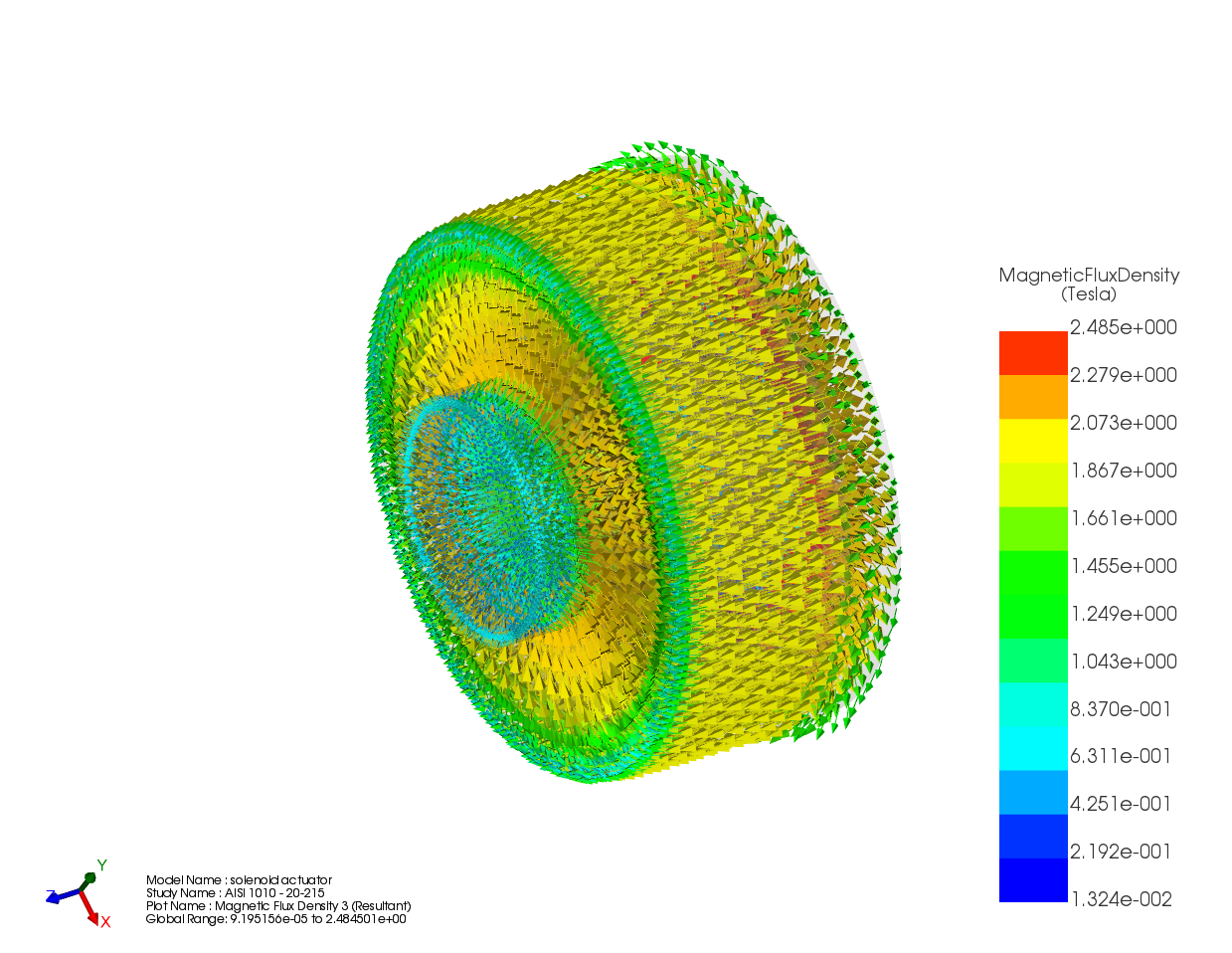

Flux Density (B-field):

AWG 30: Weak flux, fully linear regime, negligible force.

AWG 23: Strong flux, near knee of AISI 1010 saturation curve, efficient operation.

AWG 20: High flux with localized saturation, diminishing force returns.

Conclusion

This study shows that coil design for a DC solenoid has a major impact on plunger force, copper loss, inductance, and magnetic energy. With the same AISI 1010 magnetic circuit and almost identical copper filling factor, changing only wire gauge and number of turns caused the solenoid force to vary by nearly a factor of 40 and the copper loss to span more than two orders of magnitude.

The three coil options illustrate typical design choices for DC solenoids:

- AWG 30 (many turns, thin wire):

High resistance and low current give high inductance but very low magnetic energy.

The coil runs cool but produces only about 13 N of force, which is not practical for most solenoid actuator applications. - AWG 23 (medium wire, baseline design):

Offers a good balance of current, resistance, and ampere-turns.

It delivers more than 300 N of plunger force with manageable copper loss and operates the AISI 1010 core near the start of saturation.

This configuration is the most attractive choice for continuous or duty-cycled DC solenoid operation. - AWG 20 (few turns, thick wire):

Maximizes NI and magnetic energy and reaches almost 500 N of force.

However, the resulting current density produces more than 1.2 kW of I²R loss, which is only acceptable for short-pulse or heavily cooled solenoids.

Across all cases, the results confirm that magnetic energy correlates well with useful solenoid force, whereas inductance alone can be misleading. A high-inductance coil with very low current can store less energy and generate less force than a low-inductance coil with higher current. Keeping the copper fill factor constant allows designers to compare coil options on a fair basis, without bias from extra conductor volume.

For coil designers, the main conclusion is that the “best” DC solenoid coil is not the one with the most turns or the highest inductance, but the one that achieves sufficient ampere-turns and magnetic energy without exceeding thermal limits. In this example, the AWG 23 coil provides the most practical compromise between force, response time, and heating, while the AWG 20 coil is better suited to pulsed solenoid applications.

All simulations in this coil-design study were performed using EMWorks EMAG on the same 3D solenoid CAD model with AISI 1010 steel for the magnetic circuit.