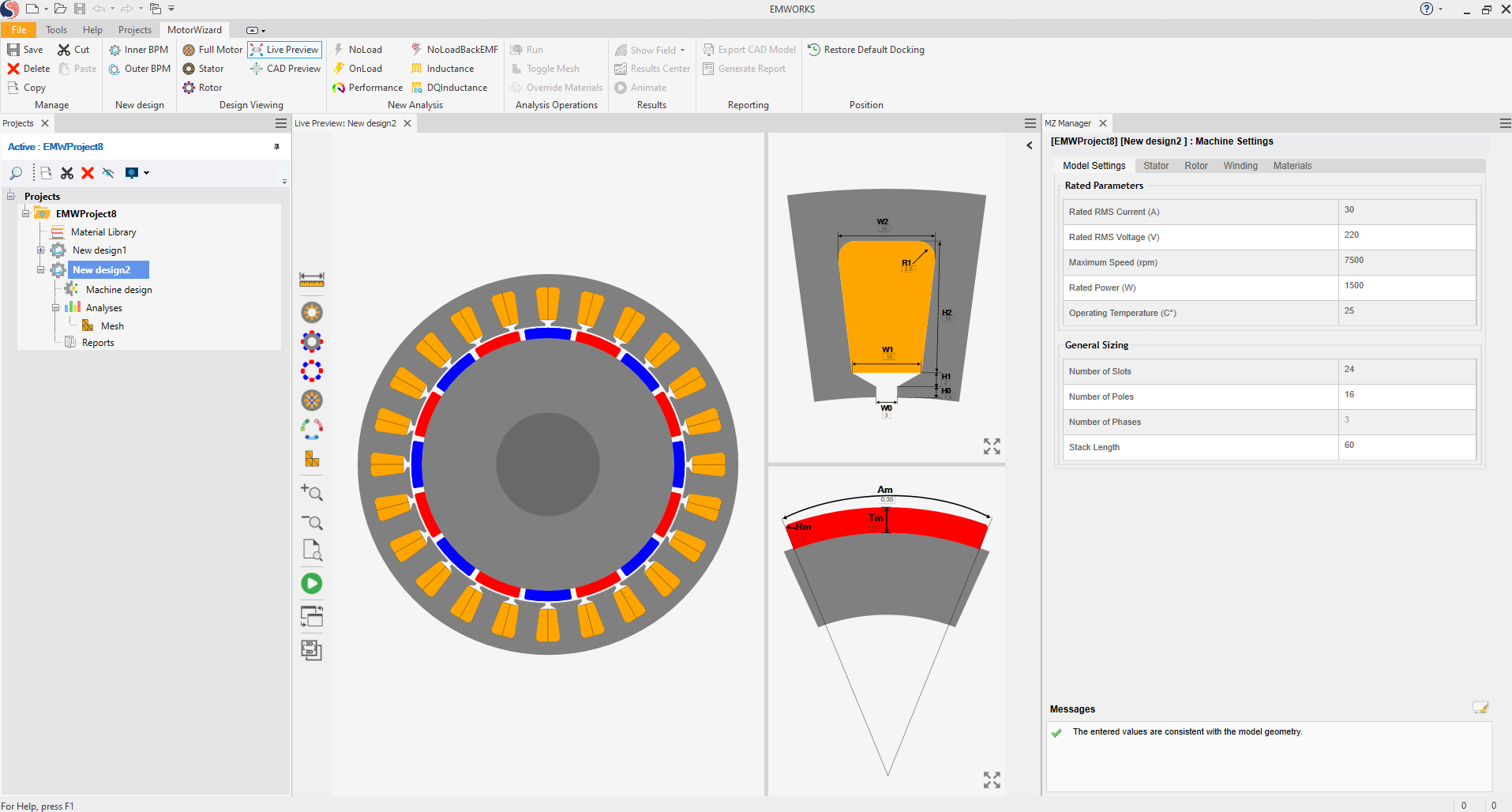

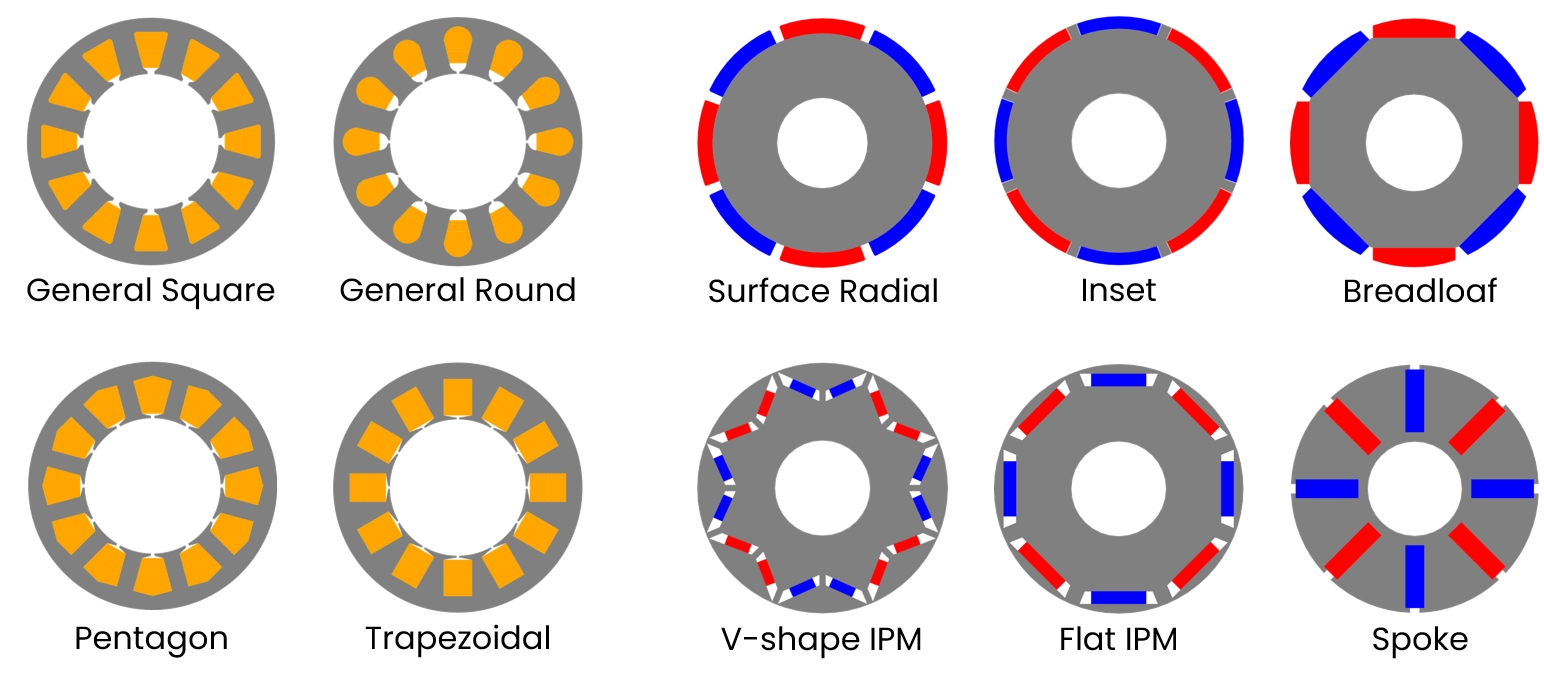

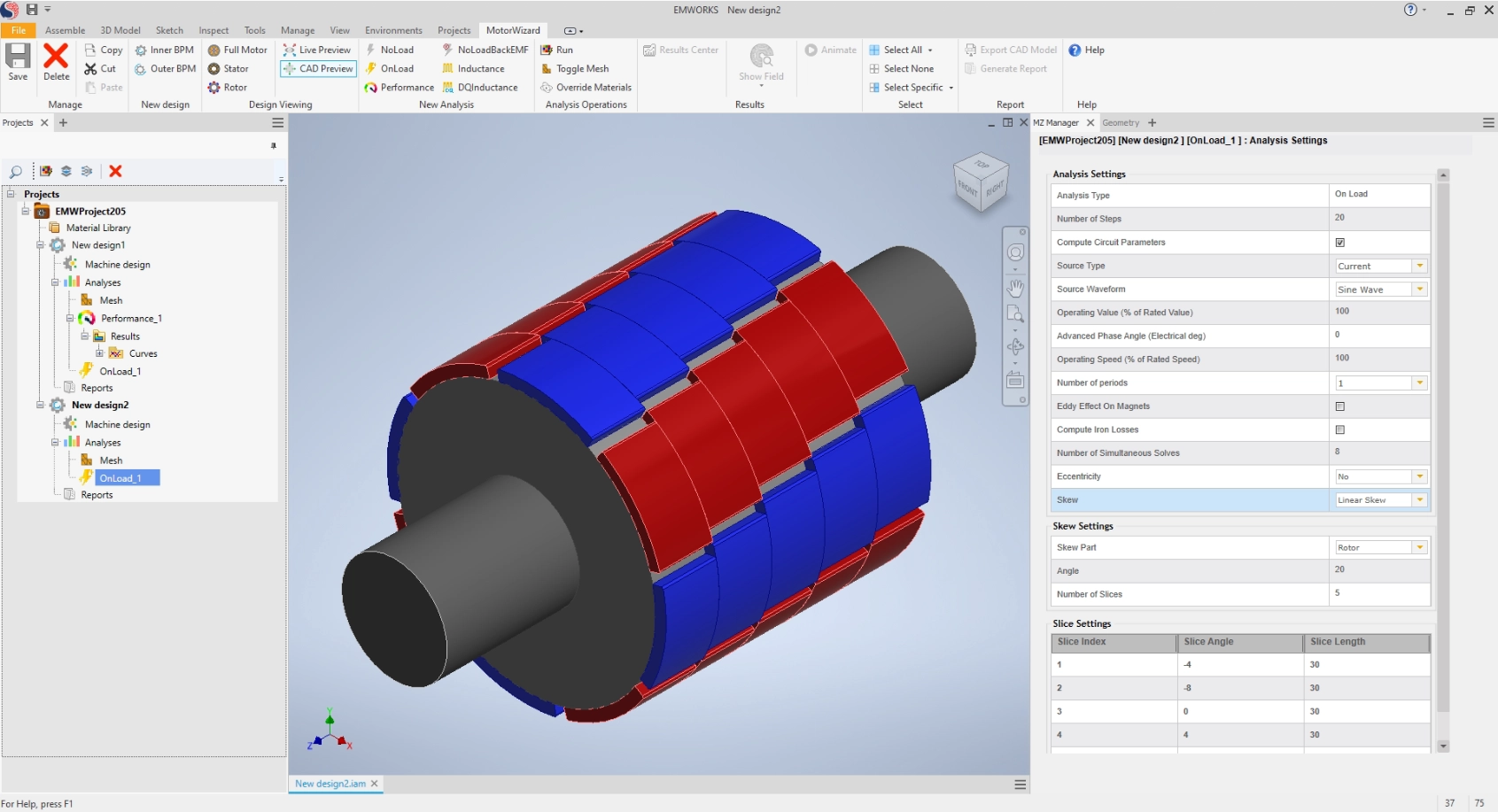

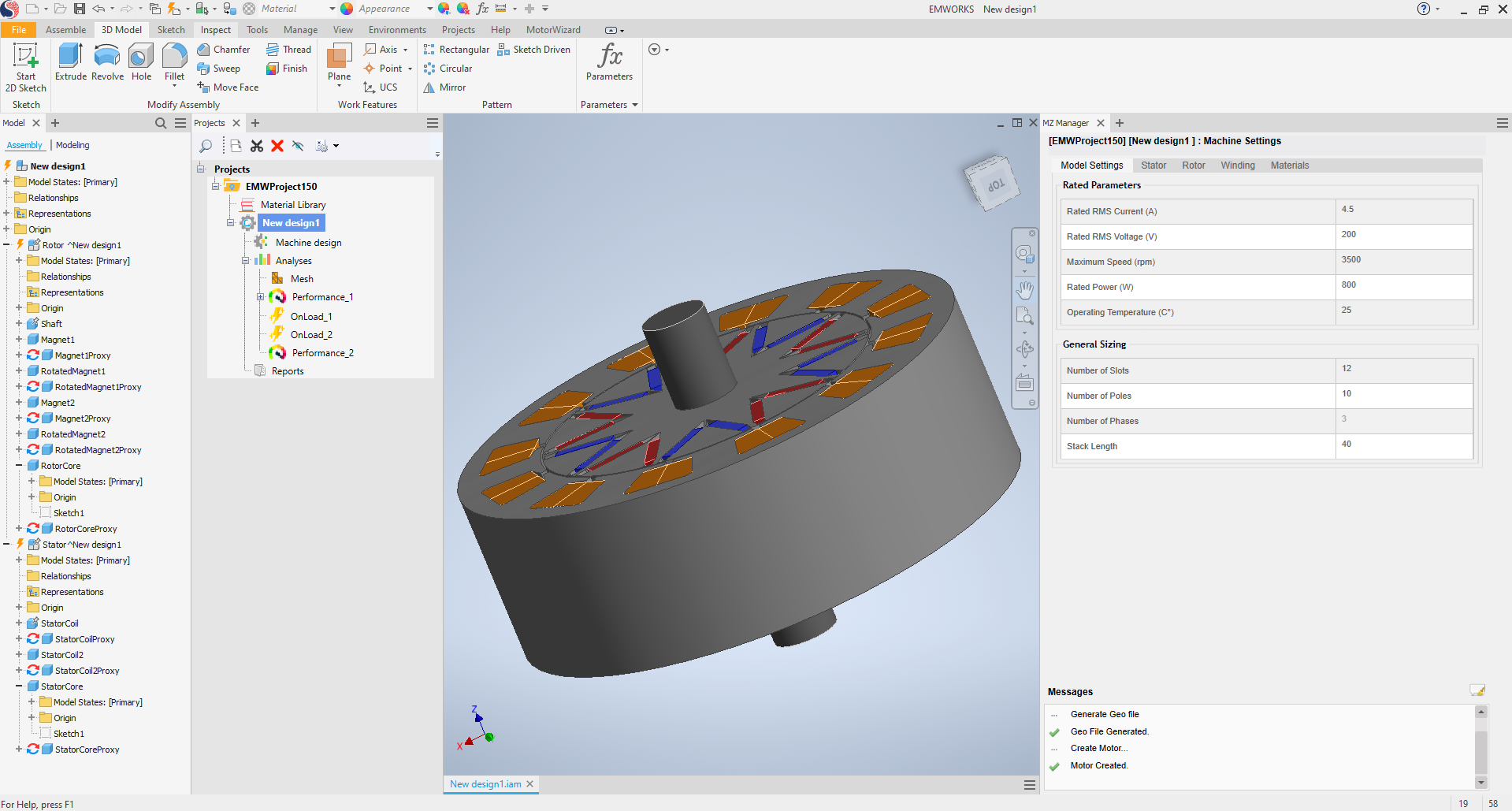

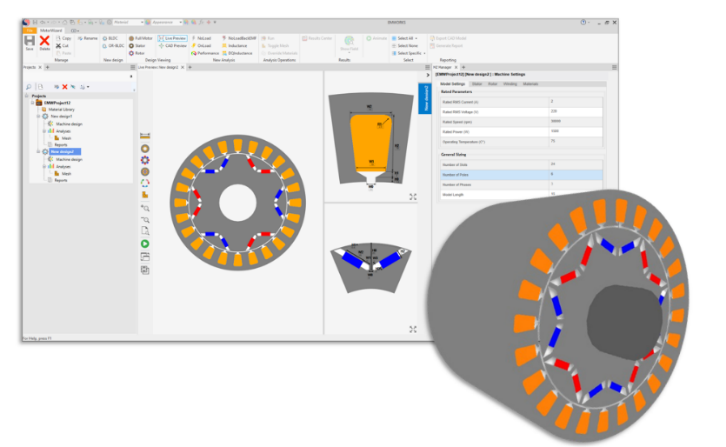

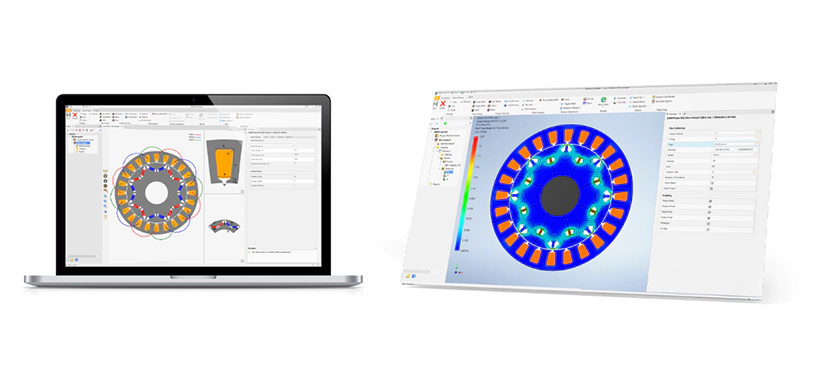

EMWORKS Motors is a template-based software designed to streamline the design and analysis of electric motors. Built on Autodesk Inventor, it features an integrated CAD environment that allows users to make real-time adjustments during the design process. This seamless integration eliminates delays, providing a smooth and efficient path from initial concept to final design.

Unlike other tools, EMWORKS Motors does not require users to purchase or have experience with Autodesk Inventor. Designers can fully leverage its advanced features, enabling faster iterations and a simplified transition from design to prototyping and manufacturing—all within a single, user-friendly platform.

-(1).webp)