Structural Coupling in EMWORKS

Structural Coupling in EMWORKS

Structural coupling in EMWORKS links electromagnetic solvers with mechanical stress/deflection analysis. It lets you transfer electromagnetic forces, pressures, and losses to a structural or thermal–structural model to evaluate deformation, stress, and fatigue.

Typical use:

Map magnetic, electric, or Lorentz forces from EM analysis onto solid bodies

Compute resulting displacement, stress, strain, and safety factors

Assess stiffness, deformation, and contact behavior under electromagnetic loading

Features of Structural Coupling with EMWORKS

Electromagnetic → structural load transfer

Map magnetic, electric, or Lorentz forces and pressures from EM analysis onto solid bodies or assemblies.Static and modal stress analysis

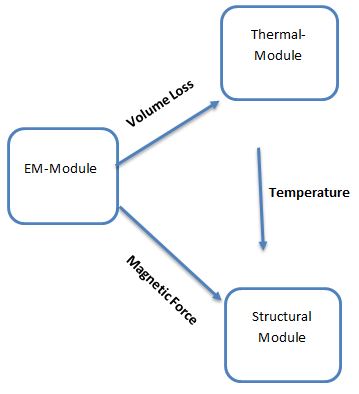

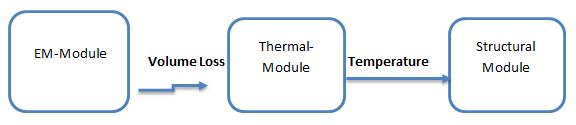

Compute displacement, stress, strain, safety factor, and natural frequencies under electromagnetic loading.Thermo-mechanical coupling

Use EM losses (J·E, core loss, dielectric loss) as heat sources and evaluate thermally induced deformation and stress.Multiphysics workflow

Electromagnetic → thermal → structural chaining in one environment for consistent geometry, mesh, and materials.Material and geometry checks

Compare alternative materials and cross-sections against stress limits, stiffness targets, and fatigue constraints.

Applications of Structural Coupling

Typical use cases:

Electric machines (motors, generators)

Magnetic forces on teeth, yokes, and rotors; deformation, vibration, and noise risk.Transformers and reactors

Core and winding forces under load, inrush, and short-circuit; clamping stress and tank loading.Solenoids and actuators

Plunger/armature forces, contact impact, and housing deformation during operation.Busbars, conductors, and rails

Electrodynamic forces under fault currents; mechanical support and bracing requirements.Magnetic bearings and levitation systems

Stiffness, deflection, and stress in rotor and stator parts under electromagnetic loads.High-power and HV equipment

Structural impact of electromagnetic forces and thermal expansion in switchgear, HV terminals, and clamps.

Results of Structural Coupling with EMWORKS

After running a study with the structural solution option, the following structural quantities can be visualized:

Displacement

Ux : Displacement in x direction

Uy : Displacement in y direction

Uz : Displacement in z direction

Ur : The resultant displacement

Stress

Von Mises Stress

SXX : Normal stress in the X direction

SYY : Normal stress in the Y direction

SZZ : Normal stress in the Z direction

SXY : Shear stress in the Y in the YZ plane

SYZ : Shear stress in the Z in the XZ plane

SZX : Shear stress in the Z in the YZ plane

PS1 : First principal stress

PS2 : Second principal stress

PS3 : Third principal stress

Stress intensity (P1-P3)

Strain

Von Mises Strain

EXX : Normal strain in the X direction

EYY : Normal strain in the Y direction

EZZ : Normal strain in the Z direction

EXY : Shear strain in the Y in the YZ plane

EYZ : Shear strain in the Z in the XZ plane

EZX : Shear strain in the Z in the YZ plane

PE1 : First principal strain

PE2 : Second principal strain

PE3 : Third principal strain

Tresca

Reaction Force

RFX : Reaction Force in the X direction

RFY : Reaction Force in the Y direction

RFZ : Reaction Force in the Z direction

3D Safety Factor

Von Mises Stress Failure Criterion

Maximum shear stress Failure Criterion

Maximum Normal Stress Failure Criterion

Mohr Coulomb Failure Criterion