Why Demagnetization Matters in PMSM Design

Permanent Magnet Synchronous Motors (PMSMs) rely on the stability of their rotor’s magnetic field to deliver efficient torque and consistent performance. When that field weakens, the result is more than a minor drop in output—it’s a loss of the motor’s fundamental strength.

Demagnetization isn’t a temporary fault. It represents a gradual or sudden reduction in magnetic strength that cannot be restored once it occurs. Even a small, demagnetized region disrupts torque balance, introduces vibration, and lowers overall efficiency. In some topologies, the only solution is to replace the entire rotor assembly —a costly process that most design engineers aim to prevent through better material choices and early-stage simulation.

What Triggers Demagnetization

A magnet’s stability depends on both its intrinsic properties and the electromagnetic environment around it. Several factors contribute to the loss of magnetization, often interacting in ways that accelerate the fault.

Thermal Stress

As operating temperature rises toward the magnet’s Curie point, its ability to retain magnetization weakens. Sustained exposure to heat, even below that threshold, can cause permanent degradation.

Reverse Magnetic Fields

During overload or short-circuit conditions, the stator may generate a reverse magnetic field that opposes the rotor’s. If the opposing field strength exceeds the magnet’s coercivity, localized demagnetization occurs.

Combined Effect

Temperature and reverse flux reinforce one another. As the magnet heats up, its resistance to reverse fields drops, meaning a current surge that is harmless at room temperature can cause irreversible damage when the motor is hot.

Why It’s More Than a Local Fault

Demagnetization doesn’t remain isolated to one spot. A single weakened pole alters the rotor’s flux balance, which increases local heating and introduces unbalanced forces. Over time, these effects can lead to mechanical stress and progressive degradation across the magnetic circuit.

In industries that depend on precision and efficiency, this gradual imbalance can quickly become critical.

- Electric Vehicles: High current peaks during acceleration or regenerative braking, combined with elevated temperatures, can repeatedly stress the magnets.

- Industrial Automation: Torque ripple reduces positional accuracy, leading to deviations and production defects.

- Aerospace Systems: Magnetic imbalance in safety-critical actuators affects reliability and response precision.

- Consumer and HVAC Motors: Efficiency losses accumulate, raising energy consumption and shortening service life.

Engineering the Design Trade-Off

Avoiding demagnetization is a challenge of balance. Engineers must weigh performance, thermal stability, and cost simultaneously.

High-performance rare-earth magnets such as NdFeB offer strong magnetic fields but are vulnerable to heat and corrosion. Ferrite magnets are cheaper and more stable at high temperature but produce lower magnetic flux density. Selecting the right material depends on the motor’s environment, duty cycle, and expected thermal behavior.

Predicting how the rotor behaves under real-world stress is complex because the problem spans multiple physics domains. Electrical losses cause heating; temperature changes magnetic properties; mechanical forces add vibration and stress. The interaction between these effects determines whether a motor remains magnetically stable or begins to degrade over time.

Using Simulation to Reduce Uncertainty

Because physical testing is both expensive and destructive, simulation has become essential for identifying demagnetization risks during the design phase.

With simulation tools such as EMWORKS EMAG, engineers can analyze the interaction between electrical loading, temperature rise, and material coercivity before a prototype is ever built. Related case studies on PMSM design and analysis show how similar coupled electromagnetic-thermal simulations are carried out using EMWORKS software.

A detailed simulation workflow enables engineers to:

- Recreate rotor geometry with accurate magnet material properties.

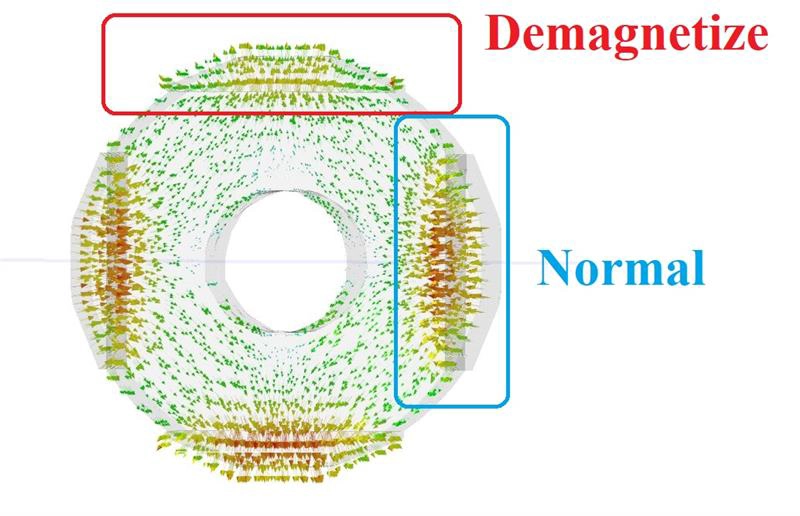

- Visualize temperature gradients and magnetic flux paths under both normal and faulted operation.

- Evaluate whether transient reverse fields exceed coercivity at elevated temperatures.

- Test alternative magnet grades or designs to identify configurations that maintain long-term stability.

By resolving these questions early, engineers can refine their designs to achieve better durability without overcompensating through excessive safety margins.

Toward More Reliable PMSMs

Demagnetization remains one of the most overlooked failure modes in permanent magnet motors. Yet it directly impacts performance consistency, maintenance cost, and system longevity.

Understanding its causes—and applying simulation to study them—helps engineers design motors that retain their magnetic integrity over time.

Simulation tools such as EMWORKS EMAG make it possible to visualize electromagnetic and thermal interactions before building physical prototypes, enabling data-driven decisions and improved motor reliability.