WHAT IS WIRELESS POWER TRANSFER?

Wireless Power Transfer (WPT) is a technique to transmit electric power without connecting wires using electromagnetic fields and waves. Generally speaking, WPT methods can be categorized to either non-radiative –near field- or radiative –far field. A power transfer is considered non-radiative if the maximum diameter of both the receiver and transmitter is less than half of the operating wavelength (𝐷𝑚𝑎𝑥 < 𝜆/2) and the transfer distance 𝑟 is less than the wavelength (𝑟 < 𝜆). Similarly, if 𝐷𝑚𝑎𝑥 > 𝜆/2 and 𝑟 < 2𝐷𝑚𝑎𝑥2 / 𝜆, it is still considered a non-radiative situation. However, a transfer is considered radiative if 𝐷𝑚𝑎𝑥 < 𝜆/2 and 𝑟 > 2𝜆 or if 𝐷𝑚𝑎𝑥 > 𝜆/2 and 𝑟 > 2𝐷𝑚𝑎𝑥2 / 𝜆. In terms of frequencies, the aforementioned conditions, translate to a frequency range of 10kHz-200MHz, and 300MHz-300GHz for non-radiative and radiative, respectively.

IMPLANTABLE BIOMEDICAL DEVICES

Nowadays, implantable biomedical devices such as cardiac defibrillators, pacemakers, and cochlear implants are widely used in old and young patients. Most of such devices are powered by batteries which constitute the bulk of the implant. Changing the batteries most often requires surgical intervention which is very undesirable, especially for the elderly population. Moreover, the batteries can become contaminated and cause serious damage because most of them are made of Lithium Iodine. Hence, the urgent need to replace the battery systems by mechanisms that use the WPT. Indeed, there is fast-growing interest in WPT for implantable devices.

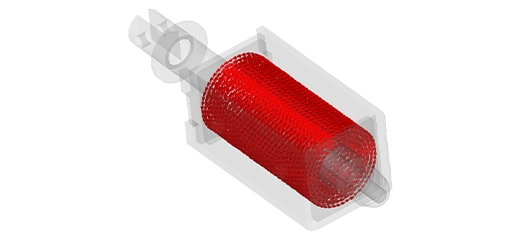

A schematic of a WPT for a pacemaker

WPT DESIGN CHALLENGES

Most of the implantable devices operate in the frequency range of 100kHz-50MHz. Therefore, the WPT can safely be considered nonradiative which uses inductive power transfer (IPT). IPT is based on two coils system where one is called the transmitter which lays outside the body and a receiver which is implanted inside the body. An implantable device such as a pacemaker requires high power, which, in turn, necessitates larger coils. In addition, the thickness of the chest varies considerably among patients which makes the IPT even more challenging to design. Other devices such as cochlear implants heavily depend on the distance between the transmitter and receiver. In some other situations, the two coils system may not be sufficient to focus the power which may necessitate the addition of a ferromagnetic cores that close the magnetic circuit. Placing ferromagnetic cores inside the body could have health implications. Furthermore, the non-planar structures of some target organs could cause the receiving coil to bend which may lead to relatively lower power transfer efficiency. In addition to technical challenges, there are regulation hurdles imposed by regulatory bodies such as the FDA. Therefore, the WPT engineers have no choice but to use simulation to validate and optimize their design long before making it. After all, the regulatory bodies' requirements often include simulation results.

Coupling coefficient between the transmitting and receiving coils vs distance

Induced voltage in the receiving coil vs distance between coils

SIMULATE IT BEFORE YOU MAKE IT

Whether your WPT design is inductive, capacitive, or radiative, use the popular EMWorks’ virtual prototyping workbench, EMS, to simulate and optimize your design. Because EMS is an add-in to SolidWorks and Inventor, virtual prototyping your WPT has never been this easy. EMS is equipped with the best-in-class postprocessor to view your results such as force, capacitance, resistance, inductance, losses, electric field, magnetic field, flux, current, voltage, and more.

Flux density around the coils

SUMMARY AND TAKEAWAYS

Wireless Power Transfer is set to revolutionize implantable medical devices, offering a safer alternative to battery-powered implants. With the help of EMWorks’ EMS simulation, designers can overcome the technical and regulatory challenges involved in WPT implementation, ensuring efficient, compliant power solutions. This advancement not only enhances device reliability but also significantly improves patient safety and convenience, marking a significant step forward in medical technology.

Current flow in the transmitting coil