The term “DC motor” is traditionally used to refer to “brushed DC motors” which consist of a stator, rotor, brushes,

and field windings. The function of brushes and commutators is to switch the polarity whereas field winding is used to produce the magnetic field required for energy conversion.

If the winding is replaced by permanent magnets, the rotating magnetic field is then generated without the need for separate winding. Moreover, the losses in the field will be eliminated.

There has been a significant improvement in permanent magnet technology in the last few years.

Permanent magnets like Neodymium Iron Boron (NdFeB) and Samarium Cobalt (SmCo) are the most popular.

Now, if permanent magnets are placed on the rotor, the armature winding will be stationary and hence brushes can be removed. This has two advantages,

- Resistive losses in brushes are eliminated

- Maintenance and safety issues are also taken care of

Thus, the DC motor with permanent magnets without brushes is called a brushless DC motor or simply a BLDC motor.

How does the BLDC Motor Work?

BLDC motor works on the same principle as brushed DC motor. The Lorentz force law states that whenever a current-carrying conductor is placed in a magnetic field it experiences a force. When the stator coils are excited, they become an electromagnet and start producing the uniform magnetic field in the air gap. Even though the source of supply is direct current, the inverter switches such that it generates an AC voltage waveform. Hence, due to the force of interaction between the electromagnet stator and permanent magnet rotor, the rotor continues to rotate as shown below.

Working of BLDC Motor [1]

BLDC Motor Applications

Due to declining costs and better performance, brushless motors are gaining popularity in various applications such as varying loads, constant loads, and positioning applications in the fields of industrial control, automotive, aviation, automation systems, health care types of equipment, etc.

BLDC Motor Applications

Types of Conduction Modes

There are two types of conduction modes: 120° and 180° modes as shown below.

(a) 120° Conduction Mode, (b) 180° Conduction Mode [2]

In the 120° conduction mode, the current flows through the two phases at any time. Let us consider, that the current flows through phases A and B; from the positive end to the negative end of the DC bus then the remaining third phase C is kept floated. In this switching scheme, each phase per arm is turned on for 120 electrical degrees and turned off for another 60 electrical degrees. Therefore, the peak magnitude of phase voltage in this conduction mode is Vdc/2.

For the 180° conduction mode, all three phases A, B, and C, are turned on at any time. This means that either the upper-side or lower-side power transistors of the same arm are turned on at any one time. Moreover, the phase A current is equal to the sum of both phase B and C currents but of course with the inverse sign. The magnitude of the phase voltage in this conduction mode at two different steps is Vdc/3 and 2Vdc/3.

EMWorks Solution

To simulate the BLDC motors, the first step is to obtain it CAD model, then assign materials to all the parts of the motor, set the excitation - either voltage driven or current driven, and lastly adjust the advanced parameters for each model under different case studies.

EMWorks2D is an electromagnetic simulation software that uses the finite element to solve magnetic, electric, and transient problems. EMWorks2D is fully embedded in SOLIDWORKS and Inventor platforms which allows users to solve complicated designs and to carry out electromagnetic and multi-physics studies hence achieving results efficiently and accurately.

The design specifications of the BLDC motors used for further analysis are shown below.

2D CAD of BLDC Motor (a) 24 Slots and 16 Poles (b) 24 Slots and 20 Poles

Design specifications:

| Specifications | BLDC motor |

| Configuration (slots/poles) | 24/16 and 24/20 |

| Based speed | 766.66 rpm |

| DC bus voltage | 150 V |

| Stack length | 100 mm |

| Stator and rotor core material | M27 steel |

| Permanent magnet | NdFeB (N28UH) |

| Conductor material | Copper |

The following figures show some of the results obtained using EMWorks2D for BLDC motors under the no-load and full-load conditions.

No-Load Results

- No-load flux linkage

No-Load Flux Linkage Waveform vs Time – 16 Poles and 20 Poles BLDC Motor

- Back-EMF

No-Load Back-EMF Waveform vs Time – 16 Poles and 20 Poles BLDC Motor

- Magnetic flux density

Magnetic Flux Density Mapping – 16 Poles and 20 Poles BLDC Motor

The back-EMF obtained for 20 poles BLDC motor is more sinusoidal compared to 16 poles design. This mainly depends on the slots per pole per phase (SPP) ratio and winding configuration selected. Here, the SPP ratio for 20 poles design is 0.4 whereas for 16 poles design is 0.5. It was also observed that due to the high amount of magnets volume, the peak magnetic flux density for the 20 poles design increased to 1.63 T compared to the 16 poles design which has 1.51 T.

On-Load Results (16 Poles Design)

- Input voltage

Input Voltage for 16 Poles Design in 120° and 180° Conduction Modes

For 120° conduction mode, the peak input voltage is equal to 75 V which represents Vdc/2. Whereas in the 180° conduction mode, the peak input voltage is equal to 100 V, which represents 2Vdc/3.

- Induced current

Induced Current for 16 Poles Design in 120° and 180° Conduction Modes

- Electromagnetic torque

Electromagnetic Torque for 16 Poles Design in 120° and 180° Conduction Modes

During a steady-state operation, the magnitude of peak induced current under 180° conduction mode is higher compared to the 120° conduction mode. This is because the input supply voltage, for the same DC bus voltage, was higher for the 180° conduction mode i.e., 2Vdc/3. Hence the on-load average electromagnetic torque obtained for 180° conduction mode is 80.1 Nm whereas for 120° conduction mode is 73.9 Nm.

On-Load Results (20 Poles Design)

- Input voltage

As the number of poles increases from 16 to 20, for the same base speed of 766.66 rpm, the frequency of an input voltage also increases as shown below.

Input Voltage for 20 Poles Design in 120° and 180° Conduction Modes

- Induced current

Induced Current for 20 Poles Design in 120° and 180° Conduction Modes

- Electromagnetic torque

Electromagnetic Torque for 20 Poles Design in 120° and 180° Conduction Modes

As observed in the 16 poles design, similarly in the 20 poles design during a steady-state operation, the magnitude of peak induced current under 180° conduction mode is higher compared to the 120° conduction mode. The on-load average electromagnetic torque obtained for 180° conduction mode is 86.9 Nm whereas for 120° conduction mode is 61.0 Nm.

Thermal Study

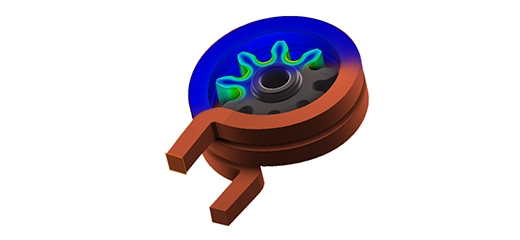

Temperature Rise in 16 Poles and 20 Poles BLDC Motor Designs

The rise in temperature due to the current carrying stator coils is around 141.8° C and 144° C for 16 poles and 20 poles designs, respectively. The overall rise in temperature in both designs is almost the same and well within the insulation’s maximum permissible limit.

Conclusion

Brushless DC (BLDC) motors represent a significant advancement in the world of electric motors, combining enhanced efficiency, reliability, and reduced maintenance needs into a compact form factor. Their versatility allows them to excel in diverse applications, from industrial machinery to electric vehicles, offering a sustainable and powerful alternative to traditional brushed motors. The transition to BLDC motors not only marks a step forward in motor technology but also aligns with the broader movement towards more sustainable and efficient electrically powered solutions.