|

Eddy current pulsed thermography ECPT : Active Infrared thermography method, based on induction heating phenomenon, is immensely developing for NDT due to its reliability and accuracy in material defect inspection.

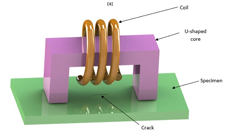

In this study, the effectiveness of ECPT technique has been investigated numerically using FEM method. The analyzed model consists of spiral coil enrolled around a U-shaped ferrite core. A schematic illustration of the ECPT technique with the studied 3D design are shown respetively in Figures 1a) and 1b).

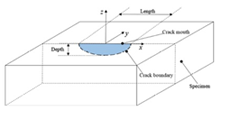

The AC magnetic module of EMS is used in this analysis, coupled to the transient thermal solver, to compute and visualize the eddy current and temperature distribution around the specimen crack. The semi-elliptical crack shape is illustrated in the Figure 2.

Figure 2 - Geometry of the tested plate containing a semi-elliptical surface-breaking crack [1]

After 500 ms of induction heating, the simulation revealed the results shown below. The current density distribution around the crack on the specimen surface shows a clear perturbation of eddy currents. The flow directions of currents are changed by the crack, leading to the surface being unevenly heated.

The generated temperature is shown in the Figure 5. The temperature of the central region of the U-shaped core on the specimen is almost evenly distributed. The maximum value is dedicated to the crack contours, reaching 23.13 °C, which is in a good coincidence with Reference [1] results (23.5 C).

|

Figure 1 - a) Schematic illustration of the ECPT [1]

b) 3D design of the studied model

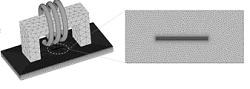

Since eddy current are localized across the skin depth of the tested plate, a fine mesh was applied to the top surface of the specimen and to the crack using the mesh control feature of EMS.

Figure 3 - Meshed model

Figure 4 - Vector plot of current density distribution

|

|

The Figure 6 shows the heated air part delimited by the crack. The temperature at the end points of the defect is much higher than that at the other parts, and it sharply decreases in the depth direction. These characteristic features are used to predict the length of the crack from the two peak temperature points of the edges, and to determine the temperature difference between the crack and the other parts.

|