In electromagnetic (EM) simulation, the quality of your results is only as good as the quality of your geometry. While simulation software has grown increasingly sophisticated, it still relies on a clean, well-prepared CAD model to generate accurate, stable, and fast results. Yet, many engineers underestimate just how much flawed geometry can compromise simulation outcomes—even when the design looks “correct” at first glance.

Why Geometry Quality Matters So Much

EM simulation solves Maxwell’s equations over a 3D domain, and that domain is defined by your CAD geometry. When the geometry is messy—filled with gaps, overlaps, or unnecessary fine features—the simulation can fail in three fundamental ways:

Accuracy - Modeling the Wrong Physics

Even a tiny gap between conductive parts can break electrical continuity, leading to unrealistic field results. A simulation can only analyze what it sees, and if your model doesn’t represent the actual structure faithfully, the fields it calculates won’t match reality.

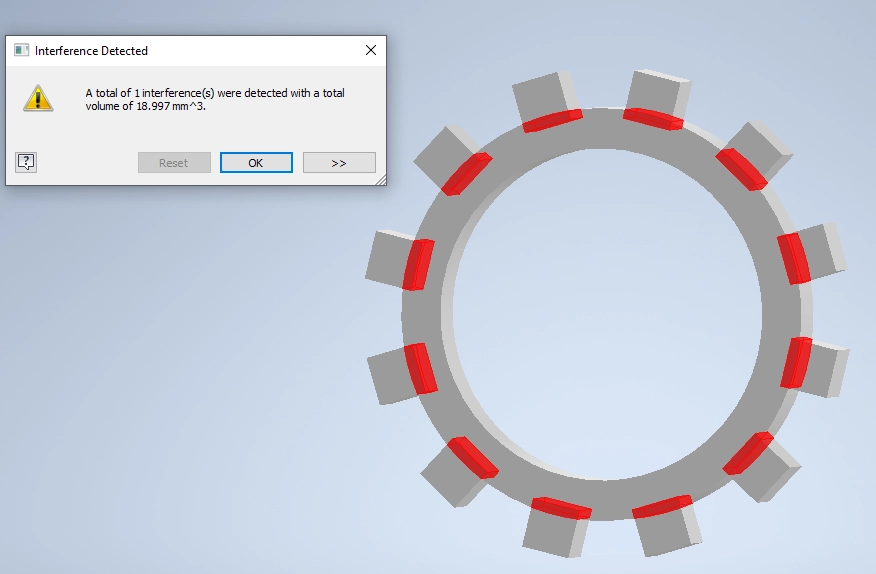

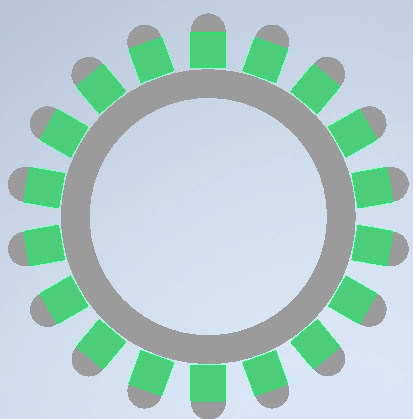

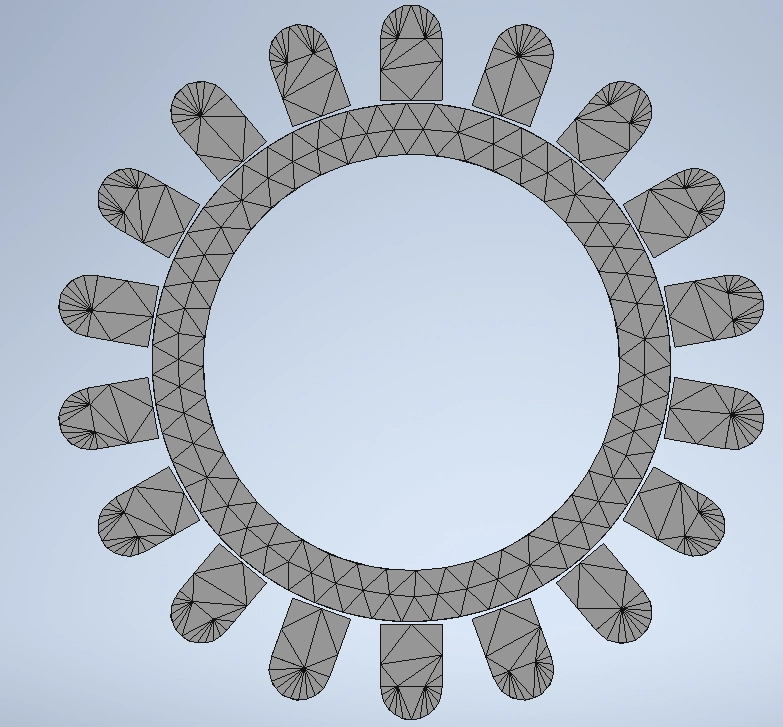

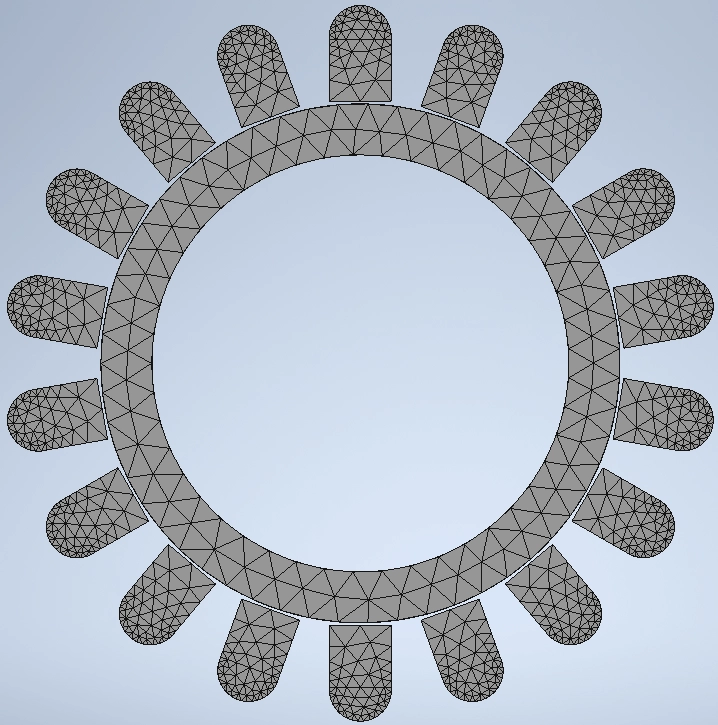

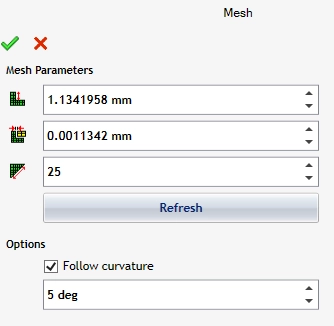

Stability - Poor Mesh = Poor Results

Simulators rely on meshing the geometry into discrete elements. Bad geometry often leads to distorted mesh cells—thin slivers, non-manifold faces, or overlapping elements—that make the solver unstable or unable to converge. You could spend hours trying to fix “solver errors” that are really just CAD problems in disguise.

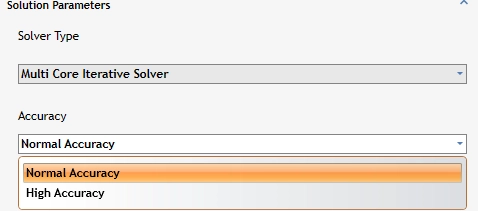

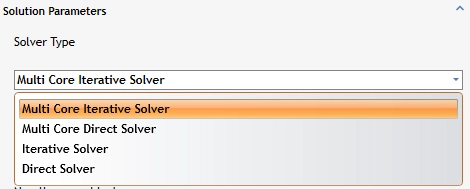

Performance - Wasteful Meshes, Slower Runs

Unnecessary small features balloon the number of mesh elements, draining memory and computing time. A logo engraving or 0.1 mm fillet might not affect EM behavior, but it can add thousands of elements to your mesh. Worse, it can force your simulation to resolve physics where none exist, slowing things down without adding accuracy.

Why This Matters More Than You Think

In practice, bad geometry doesn’t just hurt performance—it undermines confidence. Engineers end up rerunning models, applying unnecessary design margins, or chasing ghost problems caused by nothing more than a flawed mesh. Clean CAD helps reduce uncertainty, not just errors.

Tools like EMWORKS depend on accurate geometry to deliver field results that engineers can trust. When the geometry is clean, the simulation setup is smoother, the meshing is more efficient, and the solver results are more meaningful.

Up Next

In Part 2, we’ll explore the common CAD problems that sabotage simulations—and how to spot them before they slow you down.