Introduction

Magnetic gears are often perceived as low-loss devices because they contain no electrical windings. This perception has led many engineers to assume that eddy currents are negligible or nonexistent in magnetic gear systems. As a result, magnetic gears are frequently analyzed using purely magnetostatic models or transient models that neglect conductive effects.

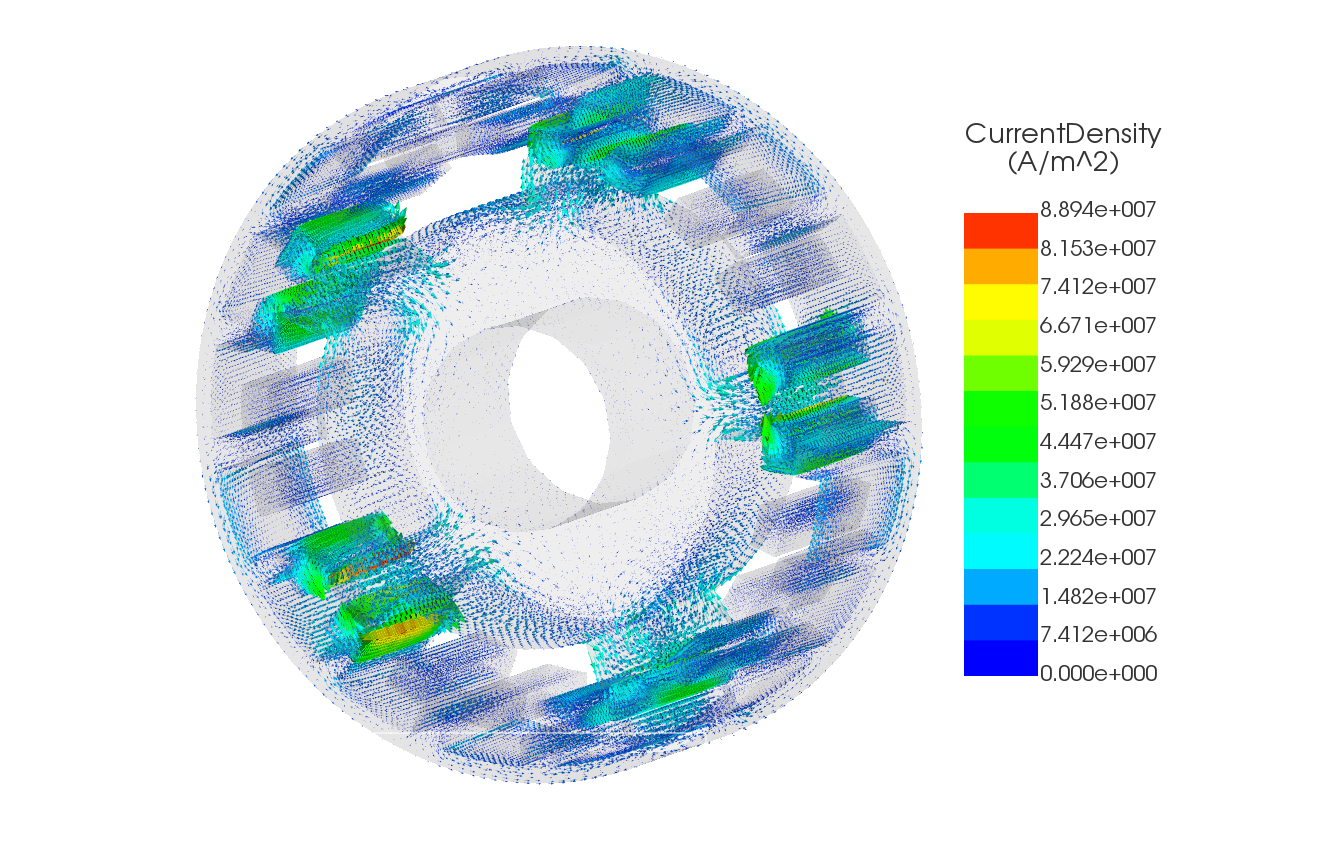

This application note demonstrates that this assumption is incorrect. Even in the absence of coils, relative motion between permanent magnets and conductive steel components induces significant eddy currents, which directly affect the transmitted torque. Ignoring these motion-induced eddy currents can lead to substantial overestimation of torque and unrealistic performance predictions.

Common Modeling Assumption and Its Consequences

A typical magnetic gear analysis often makes one or more of the following assumptions:

- Magnetostatic analysis is sufficient

- Conductive effects in steel can be ignored

- Eddy currents only arise if there is a time varying excitation in copper windings

The implicit assumption is that, because no coils are present, there is no mechanism for current induction. In reality, any time-varying magnetic field interacting with conductive materials will generate eddy currents, regardless of whether coils exist.

Model Description

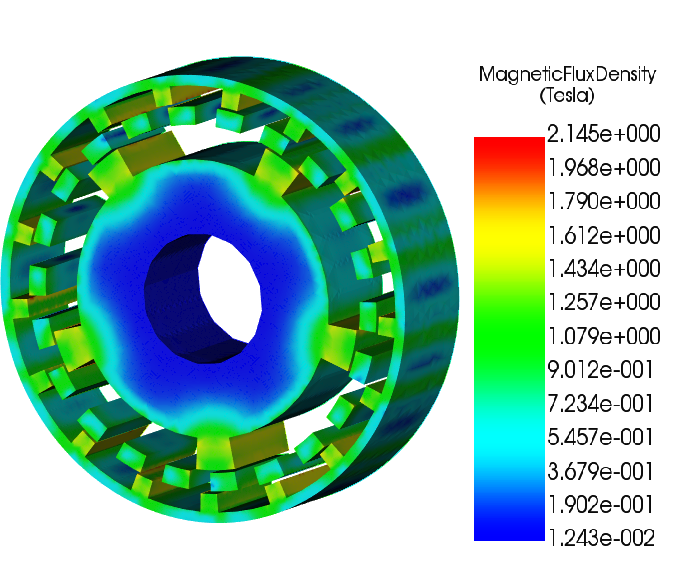

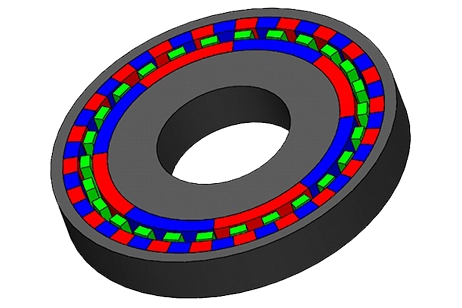

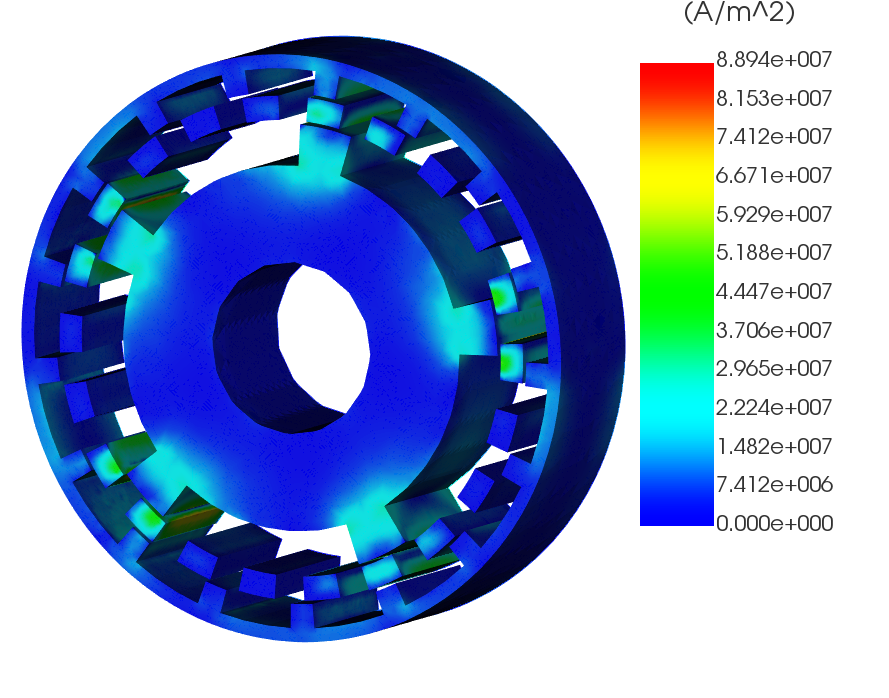

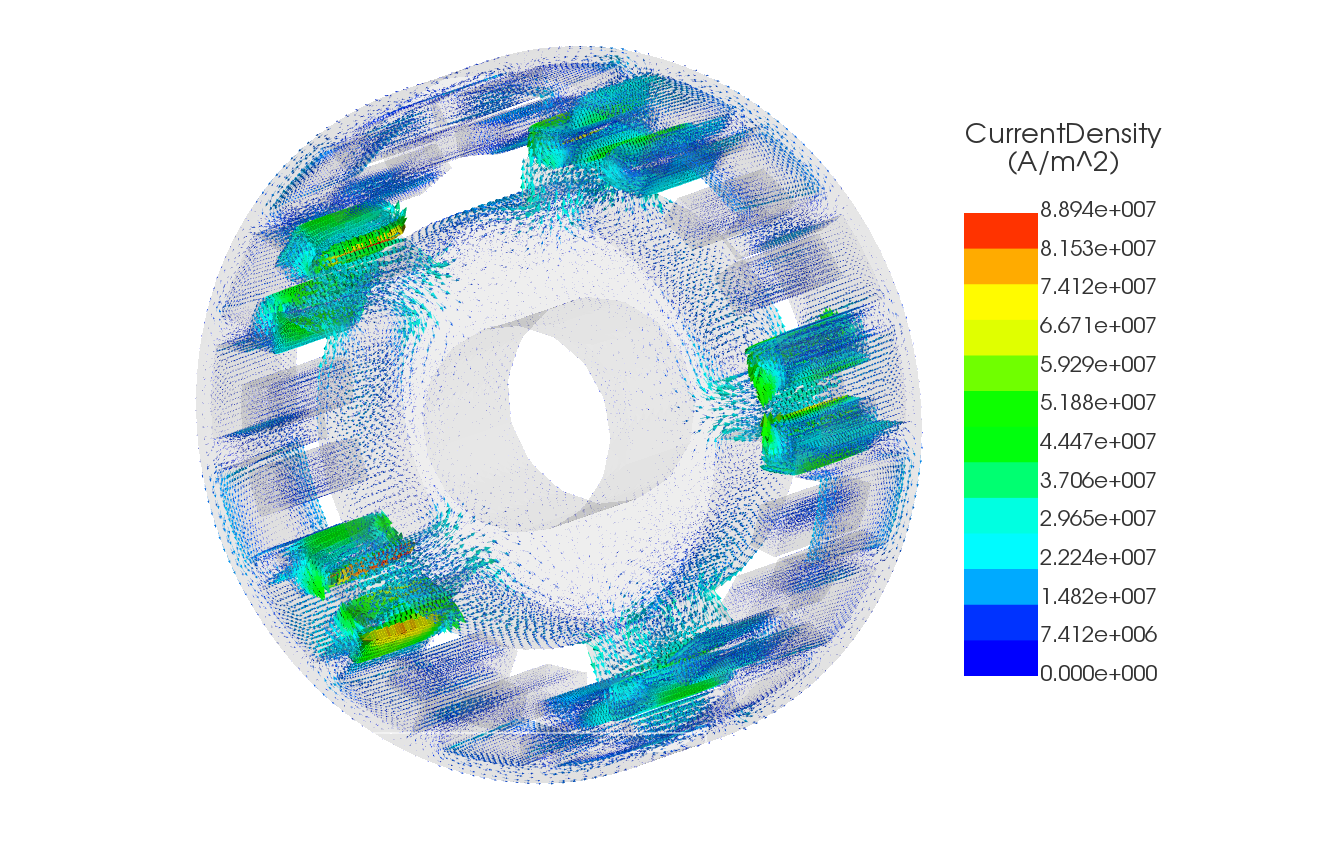

The model considered in this study is a coaxial permanent-magnet magnetic gear consisting of:

- An inner rotor with permanent magnets and steel back-iron

- A stationary ferromagnetic modulation ring

- An outer rotor with permanent magnets and steel back-iron

- Speed of rotation 3000 rpm.

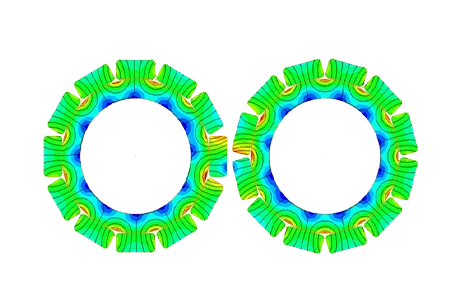

Two simulations are performed using identical geometry, materials, mesh, and operating conditions:

1. Motion ON, eddy currents OFF

2. Motion ON, eddy currents ON

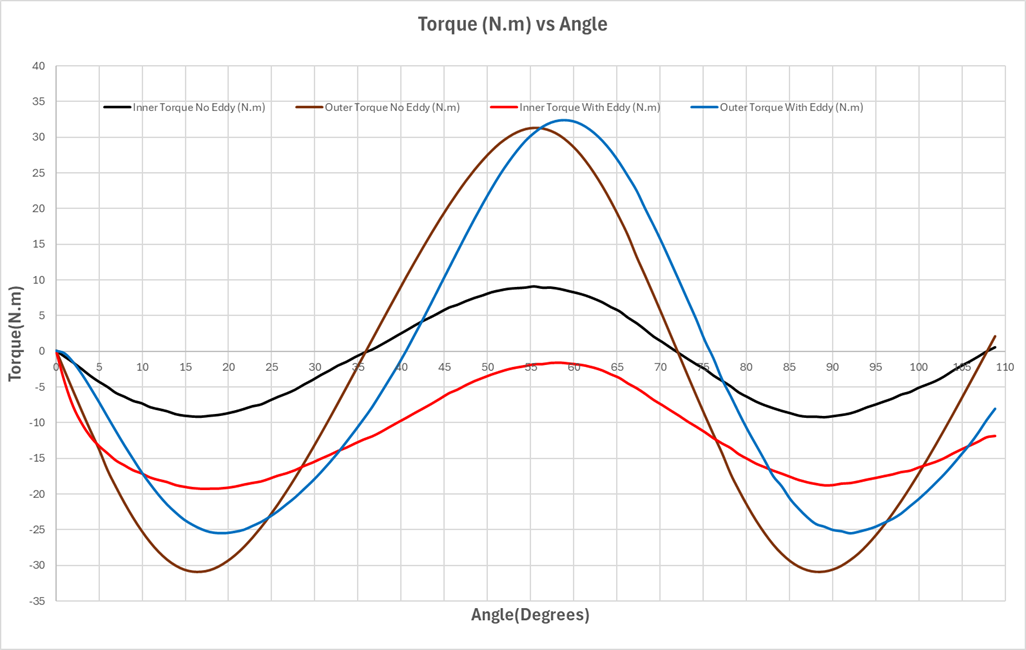

Torque Results: With and Without Eddy Currents

At a rotational speed of 3000 rpm, including motion-induced eddy currents results in a measurable reduction in both peak and average transmitted torque compared to a non-conductive transient model, despite identical geometry, materials, and magnet properties.

Origin of Eddy Currents in Magnetic Gears

Relative mechanical motion causes time-varying magnetic fields in conductive steel components. These induce circulating eddy currents that oppose the magnetic flux variation.

Engineering Implications

- Magnetic gears are not inherently free of eddy current effects

- Ignoring eddy currents can overestimate torque and underestimate losses

- Transient magnetic analysis with motion is required

- Torque predictions based on magnetostatic or non-conductive models should be interpreted as upper bounds.

Conclusion

The absence of coils does not imply the absence of eddy currents. Accurate magnetic gear analysis requires transient simulation with motion and conductivity.