High-Power Cable Simulation

Design and validate high-power cables with 3D EM and thermal analysis

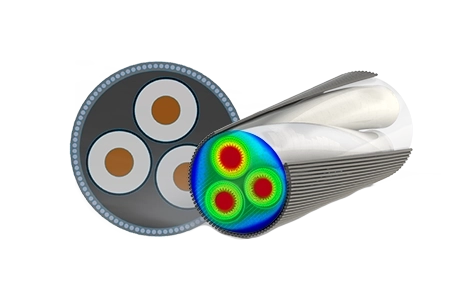

This application note analyzes a 135 kV three-phase submarine power cable buried 1 m below the seabed using AC electric simulation. The study models copper conductors, XLPE insulation, metallic sheaths, armor, and surrounding soil to compute electric field, potential, and shielding behavior at 50 Hz. Results show that grounded metallic sheaths confine the electric field inside each core, with the maximum field occurring at the conductor surface in the XLPE layer. These quantities help engineers verify insulation margins and optimize submarine cable designs for high-voltage underwater transmission.

Learn how to simulate a two-wire shielded cable at 500 kHz, capturing frequency-dependent losses, skin and proximity effects, and eddy current distribution to assess overvoltage, overcurrent, and long-term reliability in underground transmission.

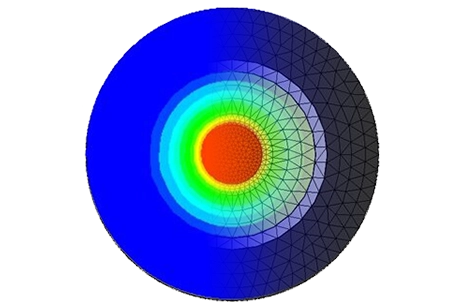

This application note studies the thermal performance of a crosslinked polyethylene (XLPE)–insulated power cable subjected to load currents from 300 A to 1600 A. A simplified 3D model includes the copper conductor, XLPE insulation, polyethylene layer, and external PVC sheath, with Joule losses in the conductor used as heat sources for the thermal calculation. The analysis predicts magnetic flux density, temperature distribution, and maximum operating temperature as a function of current, showing peak temperature at the conductor surface and a radial decay toward the outer jacket. Computed temperatures agree closely with published 2D reference results, confirming the suitability of finite element modelling for rating XLPE cables and checking thermal margins under service conditions.