Introduction

With the rapid growth in global energy needs, wind turbines have emerged as a reliable solution to face the problem of climate and ecological changes. Direct-drive permanent magnet synchronous machines (PMSMs) used in wind turbines have received significant attention thanks to the elimination of gearbox noise and their low maintenance cost. PMSMs provide high energy efficiency and a better permanent magnet yield. In addition, the absence of a circuit exciter reduces the maintenance cost of the generator’s rotor and minimizes its losses, which helps achieve better thermal effectiveness and higher performance.

Machines Used for Energy Conversion of Wind Systems

The most popular wind generators currently used in wind conversion chains are asynchronous generators (such as squirrel cage generators, and double-fed asynchronous generators) and permanent magnet synchronous generators. How to choose the right machine for your wind turbine conversion chain?

Squirrel Cage Induction Generators (SCIGs)

SCIGs operate at a fixed speed. They are standardized and have a low maintenance cost thanks to the use of a simple electrical interface and the elimination of power electronics. They are used for high power wind turbines (above 100KW). High speed wind turbines use gearbox which affects their mass. Besides, the energy captured is not optimal because the speed is not controllable, and its range of variation is limited. The concept of fixed speed inspired wind turbine manufacturers to use alternative types of machines adequate for the variable speed such as doubly-fed induction generators (DFIGs) and permanent magnet generators (PMSGs).

Doubly-Fed Induction Generators (DFIGs)

The DFIGs have the same operating principle of the SCIGs with a wound rotor instead of squirrel cage rotor. They are innovative compared to SCIGs working with variable speed. However, the design of the DFIGs is a complex task due to the presence of brush-ring assembly and the mechanical speed multiplier. They demand regular maintenance. In addition, their connection with the network requires power electronic interface and converters which are expensive, sensitive to over-current, and present complex control strategies during the network disturbances. To overcome the drawbacks of DFIGs, wind turbine designers used PMSGs.

Permanent Magnet Synchronous Generators (PMSGs)

The PMSGs operate at a variable speed with reduced cost and volume. They can be used directly or via mechanical gearbox. The absence of the gearbox eliminates noise problems and reduce maintenance costs. The use of the permanent magnets (PMs) provides a strong magnetic field in the air gap. In fact, the absence of the excitation circuit at the level of the rotor minimizes the losses by Joule effect which improves the energy efficiency of the generator. The brush-ring assembly is eliminated, and the design of the machine becomes simpler especially for the rotor thanks to the PMs. PMSGs with a large number of poles provide considerable mechanical torques. They use power electronics interfaces, which make them economically viable and real competitors to DFIGs. The major downside of this type of machine is the high cost of PMs.

Popular Topologies of PMSGs

The topologies of PMSGs are determined by the types of flux, rotor, and permanent magnet.

Flux Types:

There are two types of PMSGs which are axial flux and radial flux generators.

Rotor Types:

Permanent Magnet Types:

Analytical Modelling of a Surface PMSG with Internal Rotor

| Generator Specifications | Value |

| Rated power (W) | 1100 |

| Rated angular speed (rpm) | 382 |

| Pole pairs number | 6 |

| Stator yoke induction (T) | 1.4 |

| Slot number per pole per phase | 1 |

| Current surface density (A.mm2) | 2.7 |

- Bore radius

- Machine length

- Air gap thickness

- Slot width

- Magnet Angular Width per pole

- Magnet thickness

- Stator yoke thickness

- Induced flux

- Back EMF

- Induced current

| Geometric Parameters | Dimension (mm) |

| Bore radius | 83.16 |

| Air gap | 1.18 |

| Magnet thickness | 4.49 |

| Active length of the machine | 41.07 |

| Slot width | 9.68 |

| Stator yoke thickness | 11.29 |

| Rotor yoke thickness | 11.29 |

| Magnet width for one pole | 36.28 |

| Tooth width | 9.68 |

| Slot depth | 30.44 |

| Electromagnetic parameters | Value |

| Maximum vacuum flux (Wb) | 0.34 |

| Maximum vacuum induced EMF (V) | 82.5 |

| Magnetic flux density in the air gap (T) | 0.85 |

Results & Discussion

EMWorks2D Validation of the Reference PMSG

Using the virtual prototyping software EMWorks2D, we designed the indicated machine. Then, we moved to the electromagnetic analysis to determine the following parameters:

- Magnetic flux density in the air gap

- Field lines and the magnetic flux density in the machine

- Induced flux

- Back EMF

- Cogging torque

| Parameters | Analytical value | Numerical value using EMW2D | Error (%) |

| Magnetic flux density (T) | 0.846 | 0.875 | 3.3 |

| Maximum vacuum-induced flux (Wb) | 0.34 | 0.344 | 1.3 |

| Maximum vacuum-induced voltage (V) | 82.5 | 63.47 | 30 |

Analytical vs. Numerical Results

The percentage values are tolerable. The error for the flux and the maximum vacuum-induced flux is low. The back EMF error is caused by the effect of the winding technique on the PMSG. The windings are wound in a trapezoidal fashion and produce a trapezoidal back EMF. In fact, it is a BLDC machine used as a generator that has such back EMF waveform as shown in the corresponding figure.

Optimization of the PMSG

We suggest keeping the reference PMSG’s characteristics while modifying only the pole pair number and the magnet width, i.e., we kept the same volume of magnets used in the reference PMSG. The following table shows the parameters for all the used models.

| Pole pairs number of the PMSG | P = 6 | P = 8 | P = 10 | P = 12 |

| Frequency (Hz) | 38.5 | 38.5 | 38.5 | 38.5 |

| Angular velocity (rpm) | 382 | 289 | 231 | 192.5 |

| Model length (mm) | 41.07 | 41.07 | 41.07 | 41.07 |

| Magnet width (°) | 27 | 20.25 | 16.2 | 13.5 |

| Other geometric parameters | Same geometry for the 4 simulations, only the poles number and magnet width changed | |||

Models Parameters

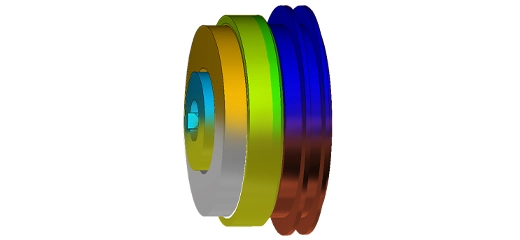

• The magnetic flux density of the optimized PMSGs

Magnetic Flux Density for PMSG with p = 8

Magnetic Flux Density for PMSG with p = 10

Magnetic Flux Density for PMSG with p = 12

• Flux linkage of the optimized PMSGs

Magnetic Flux Linkage for PMSG with p = 8

Magnetic Flux Linkage for PMSG with p = 10

Magnetic Flux Linkage for PMSG with p = 12

• Back EMF of the optimized PMSGs

Back EMF for PMSG with p = 8

Back EMF for PMSG with p = 10

Back EMF for PMSG with p = 12

FFT of the Back EMF of the Studied PMSGs

• Cogging Torque of the optimized PMSGs

Summary

| Characteristics | Reference Machine | Optimal Machine |

| P | 6 | 10 |

| Slots number | 36 | 36 |

| Slot number per pole per phase | 1 | 0,6 |

| Winding type | Distributed | Concentric |

| Machine type | BLDC | BLAC |